Detection device for valve machining

A detection device and valve technology, which is applied in measuring devices, liquid tightness measurement using liquid/vacuum degree, fluid tightness test, etc., can solve the problem of inaccurate valve detection and achieve accuracy assurance and enhanced accuracy , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

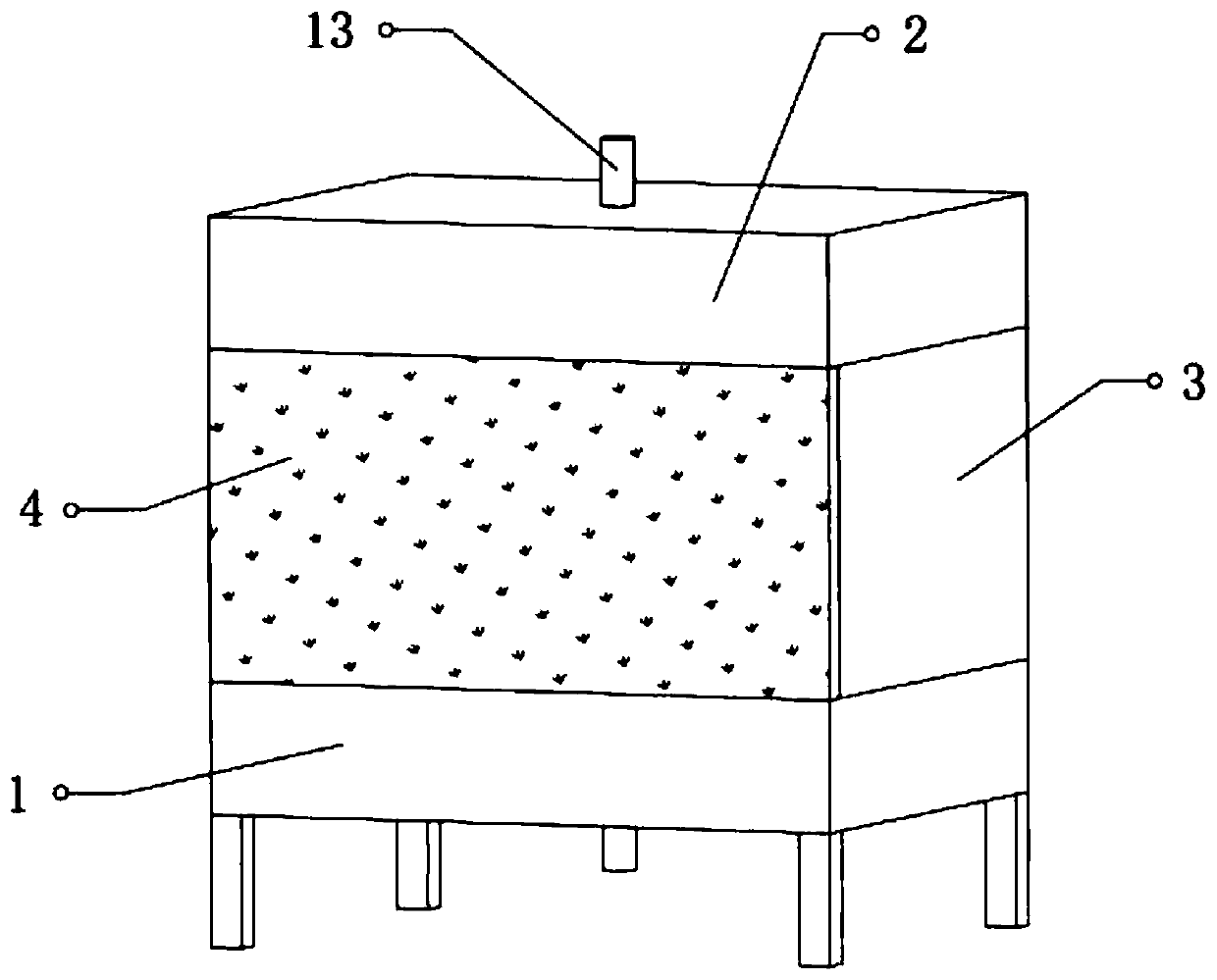

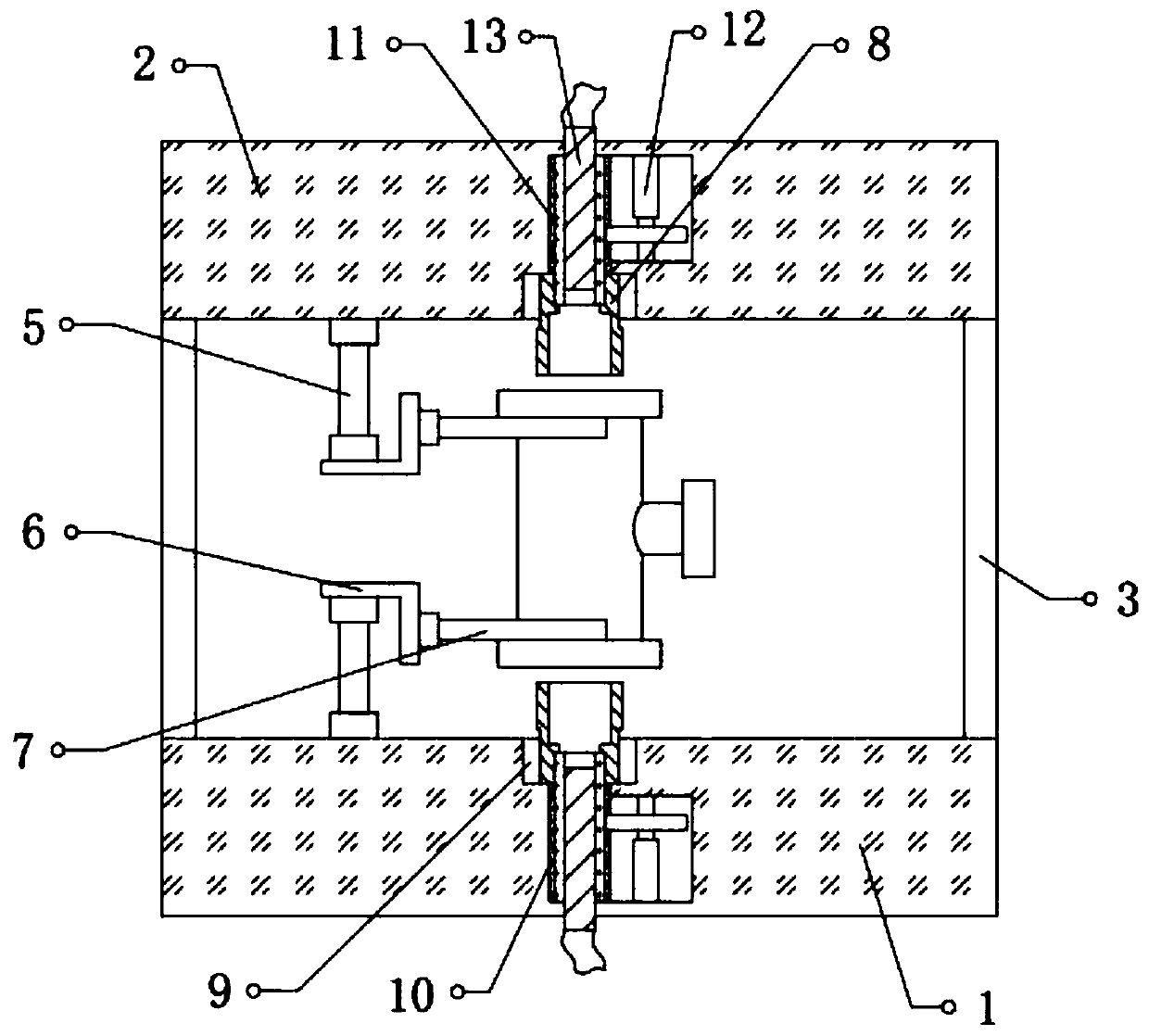

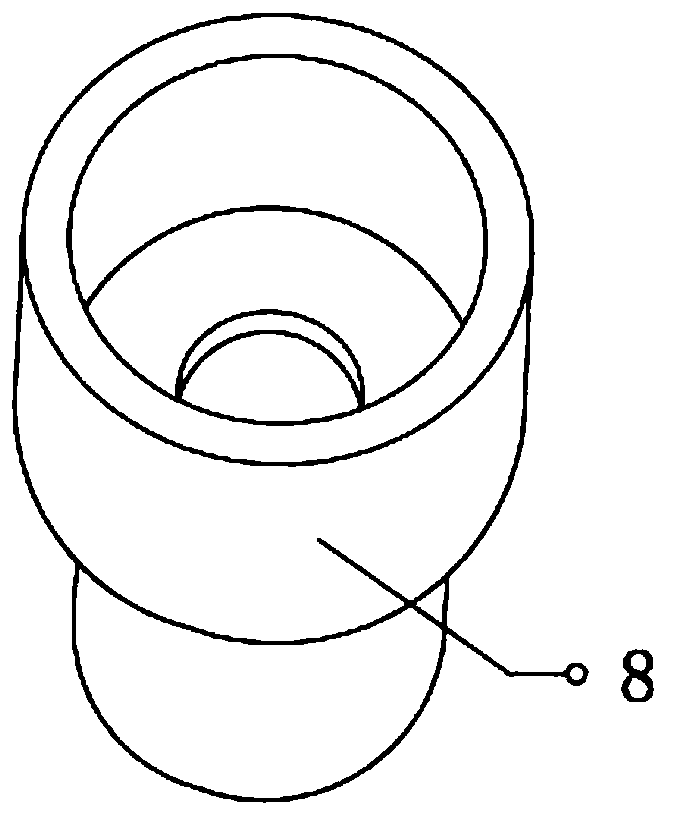

[0029] refer to Figure 1-3 , a detection device for valve processing, comprising a sealed chamber, the sealed chamber is provided with a base 1, a fixed frame 3 and a top seat 2 fixedly connected in sequence, and one end of the fixed frame 3 is provided with a sealed door 4, the top of the base 1 and the top seat 2 One side of the bottom is fixed with a cylinder 5, and one end of the cylinder 5 is fixed with a fixed frame 6, and one side of the fixed frame 6 is fixed with a horizontally arranged electric gripper 7, and the middle positions of the top of the base 1 and the bottom of the top seat 2 are uniform. A detection tube 8 is provided, and the detection tube 8 is connected with a rotating telescopic mechanism, one end of the outer wall of the detection tube 8 is adapted to the valve port, and the other end of the detection tube 8 is connected with a ventilation mechanism, and the inner wall of the sealed chamber is provided with an air pressure detector .

[0030] In th...

Embodiment 2

[0035] refer to Figure 4-5 , a detection device for valve processing, the outer wall of the detection tube 8 is detachably connected with a seal, and the top of the seal is fixed with a rubber pad 16, and the seal is set as two arc-shaped auxiliary plates 14, and the auxiliary plate 14 Both ends of the tube are fixed with fixed blocks 15, one side of the fixed block 15 is provided with a fixed hole, and the outer wall of the detection tube 8 is provided with a ring-shaped card slot 18, and the card slot 18 is compatible with the auxiliary plate 14;

[0036] The top outer wall of the rubber pad 16 is provided with a plurality of arc-shaped grooves 17, and the grooves 17 are arranged at intervals.

[0037] When in use, after the detection tube 8 is screwed into the valve port, the rubber pad 16 on the auxiliary plate 14 is pressed against the valve port, and the arc-shaped groove 17 is used to improve the sealing performance of the valve port to ensure the accuracy of the air t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com