Gel preparation method of fluorescent pigment

A technology of fluorescent pigments and fluorescent dyes, applied in luminescent materials, pigment pastes, chemical instruments and methods, etc., can solve the problems of affecting product performance, easy to produce color bleeding, etc., to achieve difficult color bleeding, good acid and alkali resistance, The effect of strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

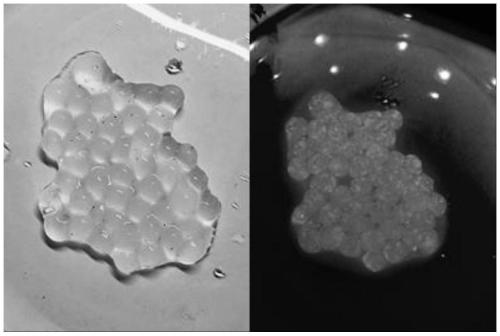

[0027] A gel preparation method for fluorescent pigments, comprising the steps of:

[0028] (1) 50g smectite and 0.2g rhodamine B are mixed and ground to obtain mixed powder;

[0029] (2) Dissolve 10g of sodium alginate in 200mL of warm water at 50°C, stir at high speed until there are no massive aggregates in the liquid, then add the mixed powder into the slurry, and continue to stir evenly for 2 hours to obtain a mixed slurry;

[0030] (3) Add 5.5g calcium chloride anhydrous to the mixed slurry while stirring, gel flocs appear rapidly in the slurry, continue to stir until the flocs disappear, form a uniform gel, and obtain a gel intermediate;

[0031] (4) Add 5g of sodium carbonate to the gel intermediate, the color of the solution changes, stir until the color is uniform and then precipitate, wash the product without floating, then centrifugally dry and grind it into powder to obtain the fluorescent pigment.

Embodiment 2

[0033] A gel preparation method for fluorescent pigments, comprising the steps of:

[0034] (1) Mix and grind 50g kaolinite and 0.5g solvent yellow 172 to obtain mixed powder;

[0035] (2) Dissolve 20g of sodium alginate in 200mL of warm water at 50°C, stir at high speed until there are no massive aggregates in the liquid, then add the mixed powder into the slurry, and continue to stir evenly for 1 hour to obtain a mixed slurry;

[0036] (3) Add 11g of anhydrous calcium chloride to the mixed slurry while stirring, gel flocs appear rapidly in the slurry, continue to stir until the flocs disappear, form a uniform gel, and obtain a gel intermediate;

[0037] (4) Add 10 g of sodium carbonate to the gel intermediate, the color of the solution changes, stir until the color is uniform and then precipitate, wash the resulting product until there is no floating color, then centrifugally dry and grind it into powder to obtain the fluorescent pigment.

Embodiment 3

[0039] A gel preparation method for fluorescent pigments, comprising the steps of:

[0040] (1) 15g saponite, 35g montmorillonite and 0.15g rhodamine 6G are mixed and ground to obtain mixed powder;

[0041] (2) Dissolve 25g of sodium alginate in 350mL of warm water at 40°C, stir at high speed until there are no massive aggregates in the liquid, then add the mixed powder into the slurry, and continue stirring for 1 hour to obtain a mixed slurry;

[0042] (3) Add 6.5g calcium chloride anhydrous to the mixed slurry while stirring, gel flocs appear rapidly in the slurry, continue to stir until the flocs disappear, form a uniform gel, and obtain a gel intermediate;

[0043] (4) Add 6g of sodium carbonate to the gel intermediate, the color of the solution changes, stir until the color is uniform and then precipitate, wash the product obtained until there is no floating color, then centrifugally dry and grind it into powder to obtain the fluorescent pigment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com