An integrated mvr evaporation concentration device

An evaporative concentration, integrated technology, applied in vertical tube evaporators, heating water/sewage treatment, etc., can solve the problem that the MVR system cannot be miniaturized, and achieve the effect of supplementing heat loss, improving heat transfer efficiency, and improving system efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

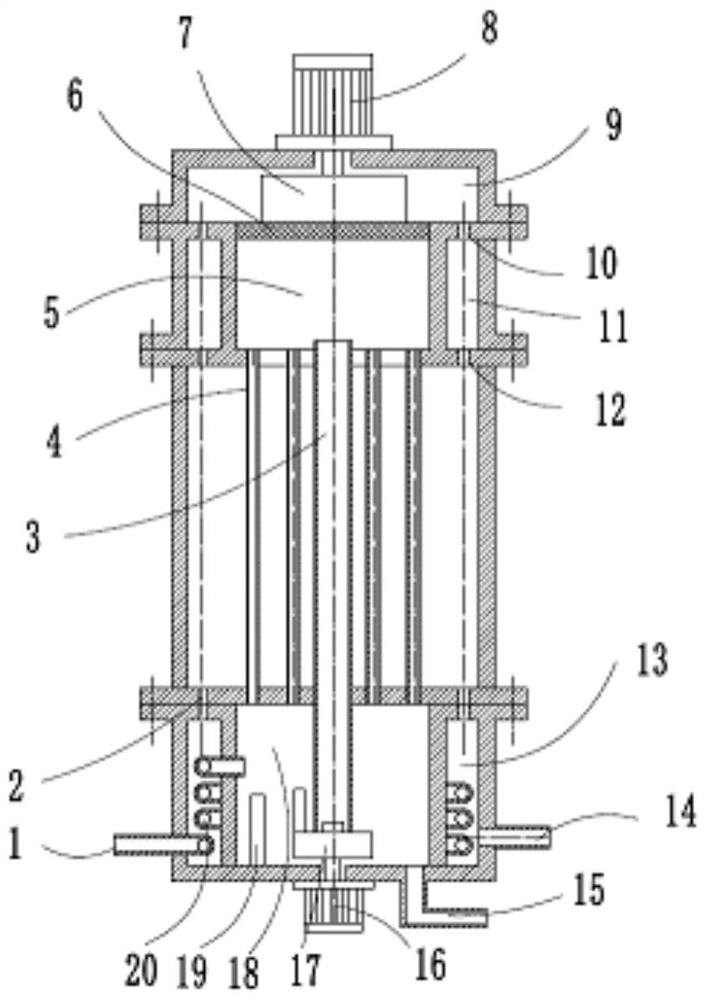

[0015] Such as figure 1 An integrated MVR evaporative concentration device as shown includes a device housing, a booster pump 17 is installed at the lower end of the device housing, and the booster pump 17 is installed in the raw material water chamber 18 to pump the heated raw material water into the separator chamber 5 , the heat exchange tube chamber 4 is connected to the raw material water chamber 18 and the separator chamber 5, and the two ends of the heat exchange tube are respectively connected to the separator chamber 18 and the raw material water chamber 5 for heat exchange and reflux; a compressor 7 is installed on the upper end of the device shell to compress The machine 7 pressurizes the steam generated in the separator, enters the heat exchange tube cavity 4 through the exhaust channel provided in the device shell, and the heat exchange condensed water enters the condensed water cavity 13 through the condensed water channel, and the condensed water cavity 13 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com