Automatic hole opening machine for large-diameter plastic winding pipe and hole opening method of automatic hole opening machine

A plastic winding tube and large-diameter technology, which is applied in the field of mechanical processing, can solve problems such as labor time-consuming, poor processing quality, and rough milling holes, and achieve the effects of ensuring processing quality, improving work efficiency, and shortening the use length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 An automatic opening machine for large-diameter plastic winding pipes

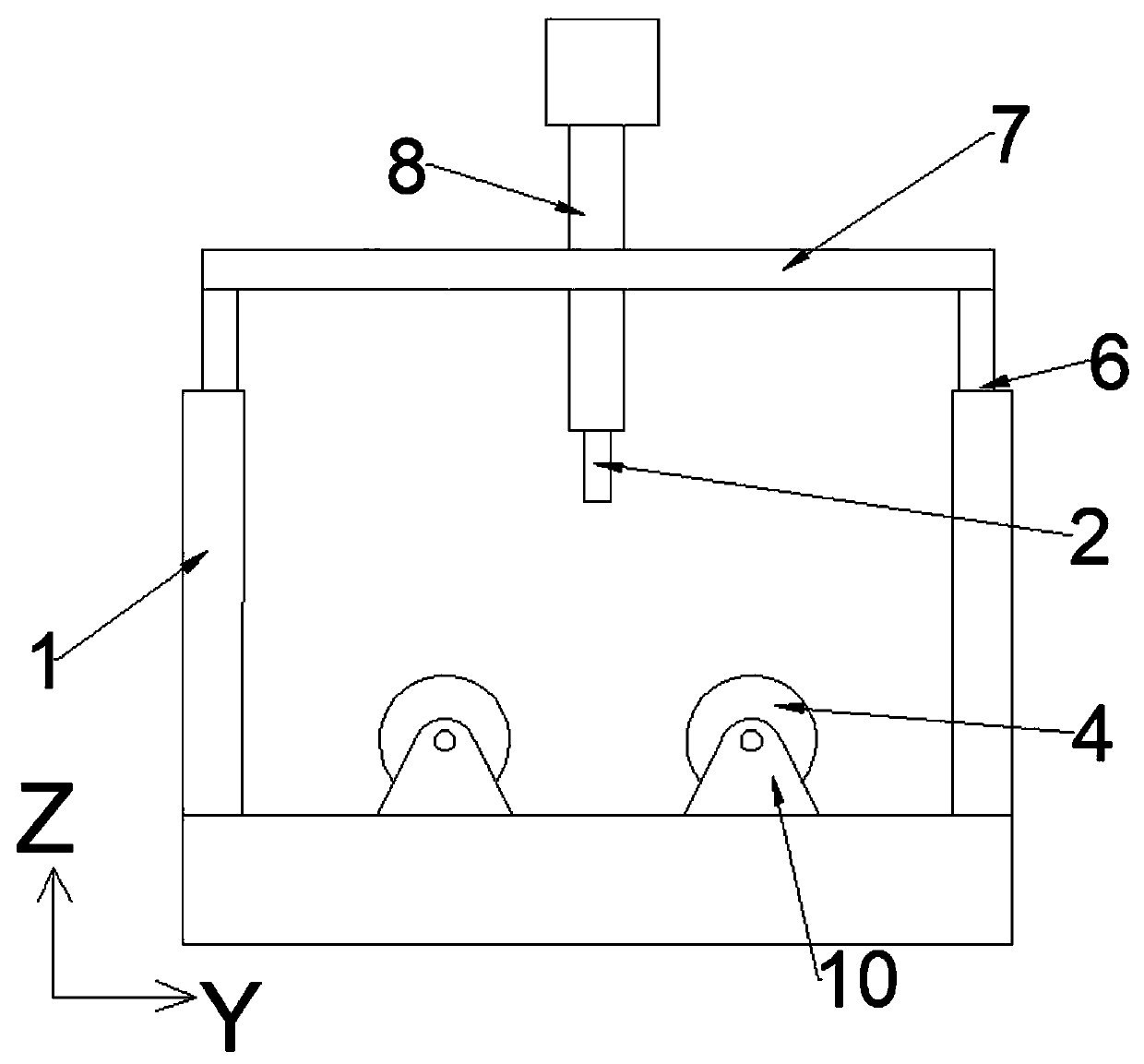

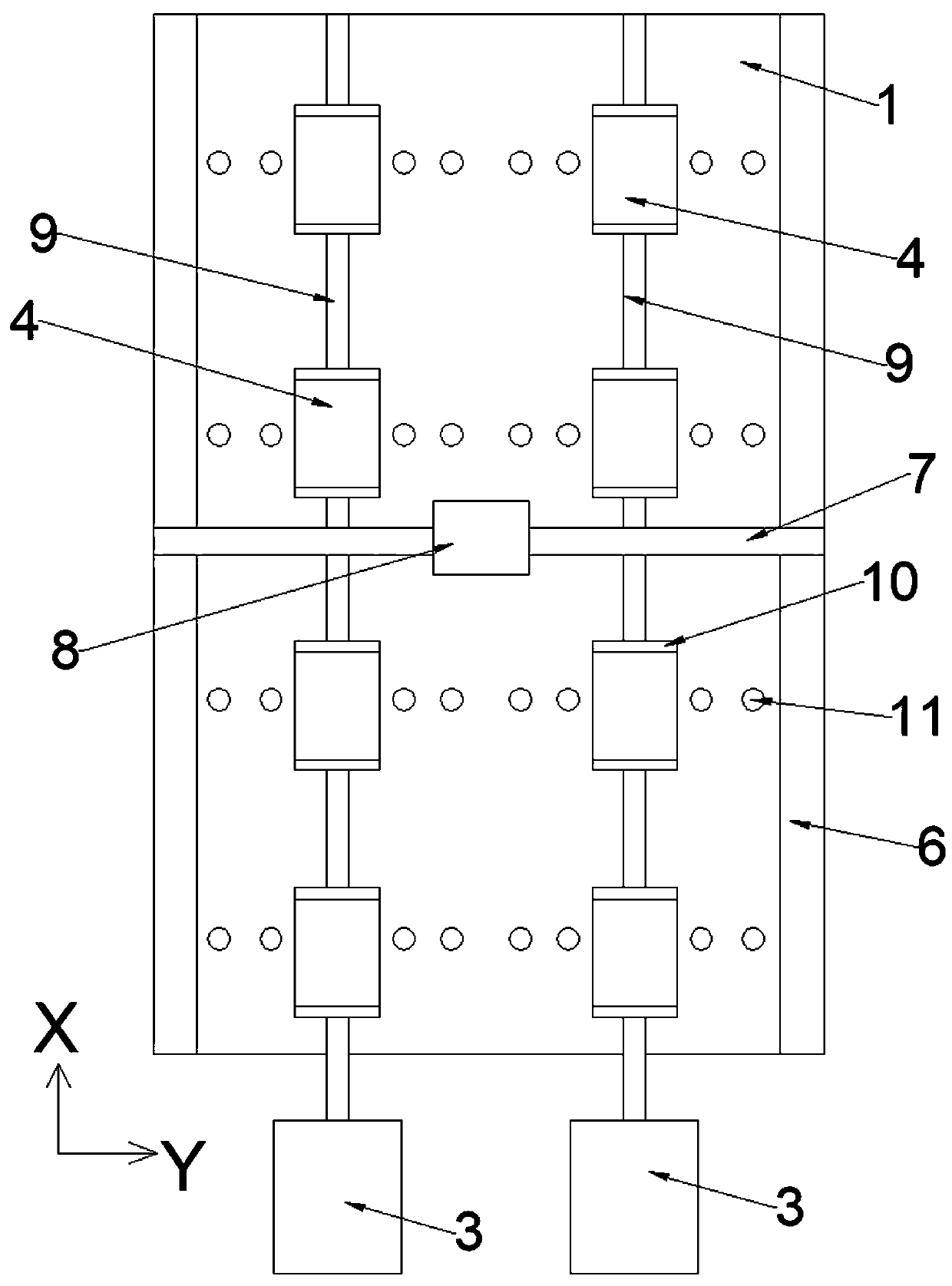

[0035] Such as Figure 1 to Figure 2 As shown, this embodiment includes a frame 1, a milling cutter 2, a first three-axis linkage device for controlling the milling hole positioning of the milling cutter 2, and an auxiliary opening device for driving a circular tube to rotate.

[0036] The first three-axis linkage device includes an x-axis moving mechanism 6 assembled on the frame 1, a y-axis moving mechanism 7 assembled at the output control end of the x-axis moving mechanism 6, and a z-axis moving mechanism assembled at the output control end of the y-axis moving mechanism 7 8. Of course, the x-axis moving mechanism 6 can be the x-axis translation mechanism in the prior art, the y-axis movement mechanism 7 can be the y-axis translation mechanism in the prior art, and the z-axis movement mechanism 8 can be the z-axis translation mechanism in the prior art. Lifting mechanism.

[0037] T...

Embodiment 2

[0043] Example 2 An automatic opening machine for large-diameter plastic winding pipes

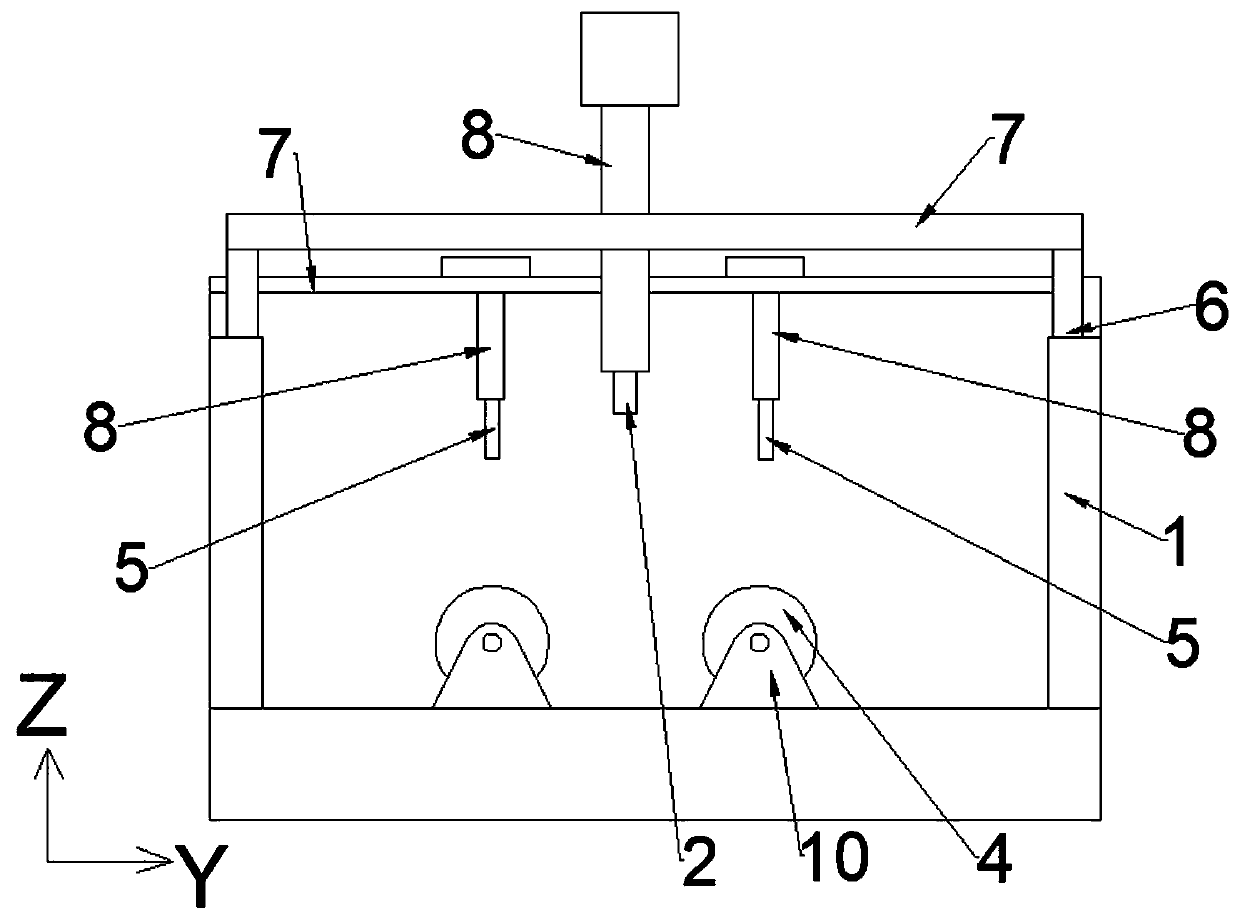

[0044] Such as Figure 3 to Figure 4 As shown, in order to increase the frictional force when the round pipe rotates and ensure the synchronous rotation of the round pipe and the rotating roller 4, for round pipes with a smaller mass, this embodiment adds the following technical features on the basis of Embodiment 1:

[0045] The large-caliber plastic winding pipe automatic opening machine also includes a pressure head 5 and a second three-axis linkage device for controlling the movement and positioning of the pressure head 5 . The pressure head 5 is in the shape of a round roller made of rubber.

[0046] The second three-axis linkage device has the same structure as the first three-axis linkage device, and both include an x-axis movement mechanism 6 assembled on the frame 1, a y-axis movement mechanism 7 assembled on the output control end of the x-axis movement mechanism 6, and a y-axis...

Embodiment 3

[0048] Example 3 Opening method of an automatic opening machine for large-diameter plastic winding pipes

[0049] In this embodiment, the automatic opening machine for large-diameter plastic winding pipes in Embodiment 2 is used to realize the milling operation of different positions on the round pipe, including the following steps:

[0050] First, the power mechanism drives all the rotating rollers 4 to use friction to drive the round tube placed on the rotating roller 4 to rotate to the working position of the milling cutter 2, that is, the round tube rotates to the working position when the milling cutter 2 initially mills holes. In order to increase the rotational friction of the round pipe, for round pipes with a small mass, the second three-axis linkage device drives the pressure head 5 to move to the pressing position, that is, to move the pressure head 5 to the surface of the round pipe and press it tightly. above the round tube.

[0051] Then, use the large-diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com