Efficient environment-friendly waste lithium ion battery recycling process

A lithium-ion battery, recycling technology, applied in battery recycling, waste collector recycling, secondary batteries, etc., can solve the problems of poor product effect, high labor cost, waste of resources, etc., to improve recycling value, reduce acid The amount of alkali used and the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

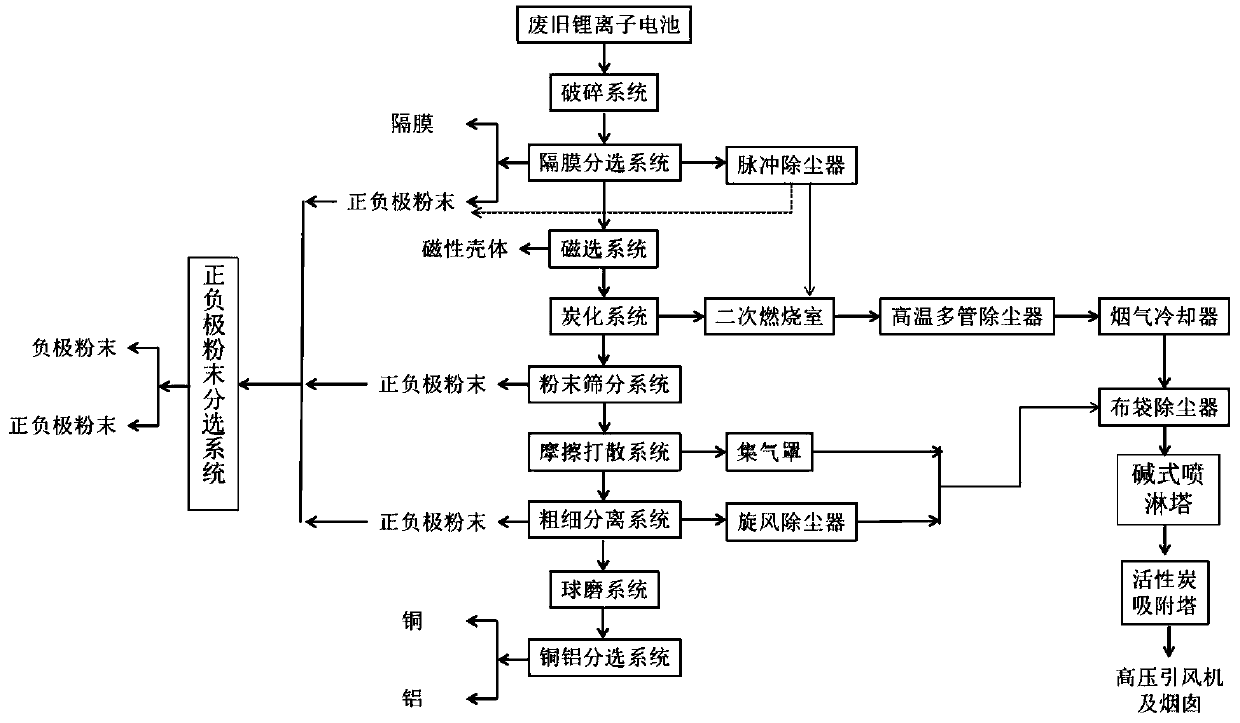

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a high-efficiency and environmentally friendly waste lithium-ion battery recycling process, including the following steps:

[0034] S1 crushing treatment

[0035] After the waste lithium-ion battery is fully discharged, the primary crushing treatment is carried out, and it needs to be screened before being sent to the next process. If the size requirement is not met, the crushing process will continue. After the primary crushing process, it will be crushed again. Continue crushing if the size requirement is not met;

[0036] S2 primary screening

[0037] After S1 treatment, winnowing treatment will be carried out, the diaphragm in it will be sent out by wind, and the powder produced at the same time will be sent to S6 for treatment. S7 treatment, the treated substances are subjected to magnetic separation treatment to separate the magnetic substances;

[0038] S3 carbonization treatment

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com