High-strength pulverizer for quantitative analysis of Chinese medicinal materials

A technique for quantitative analysis, Chinese herbal medicines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

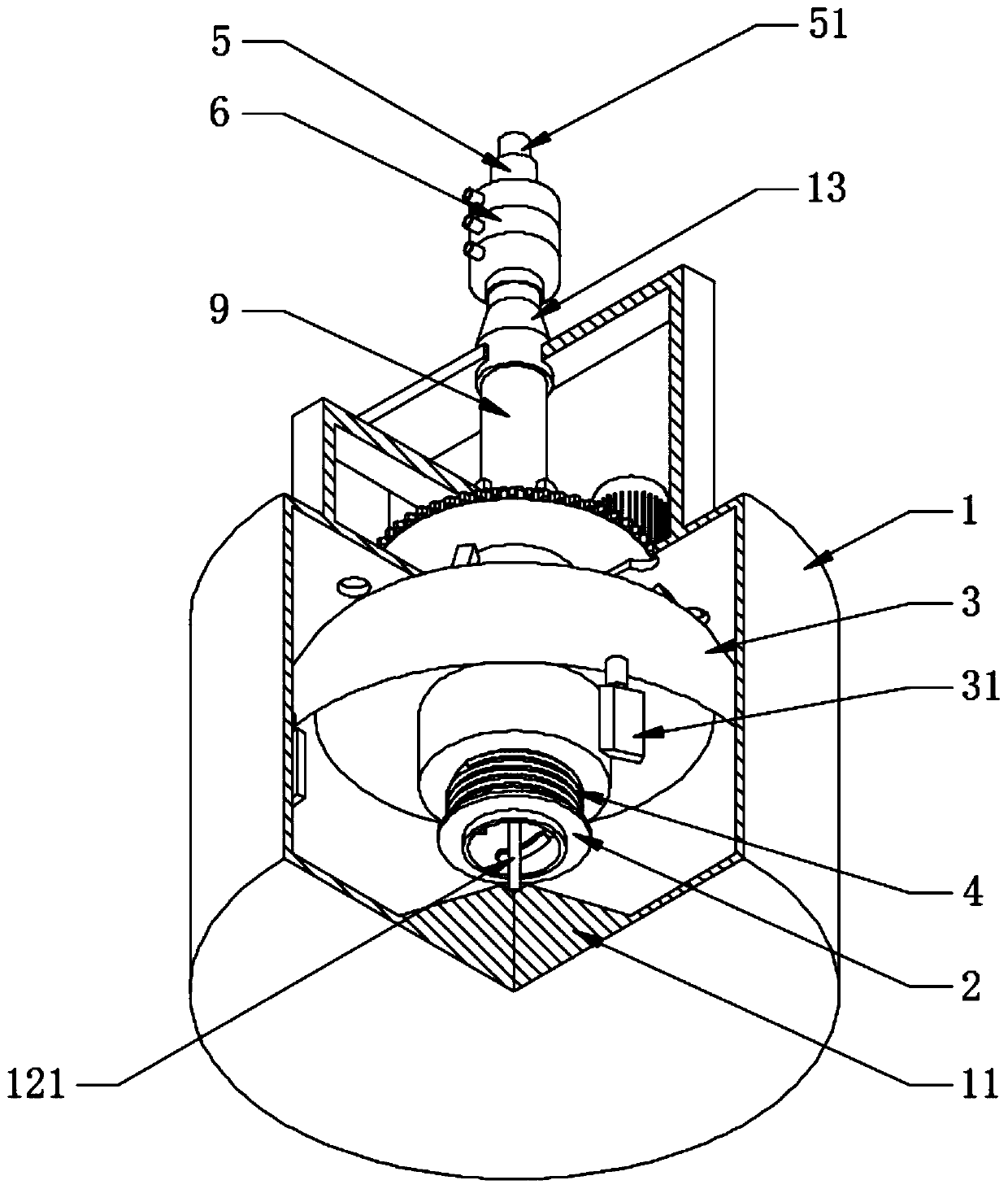

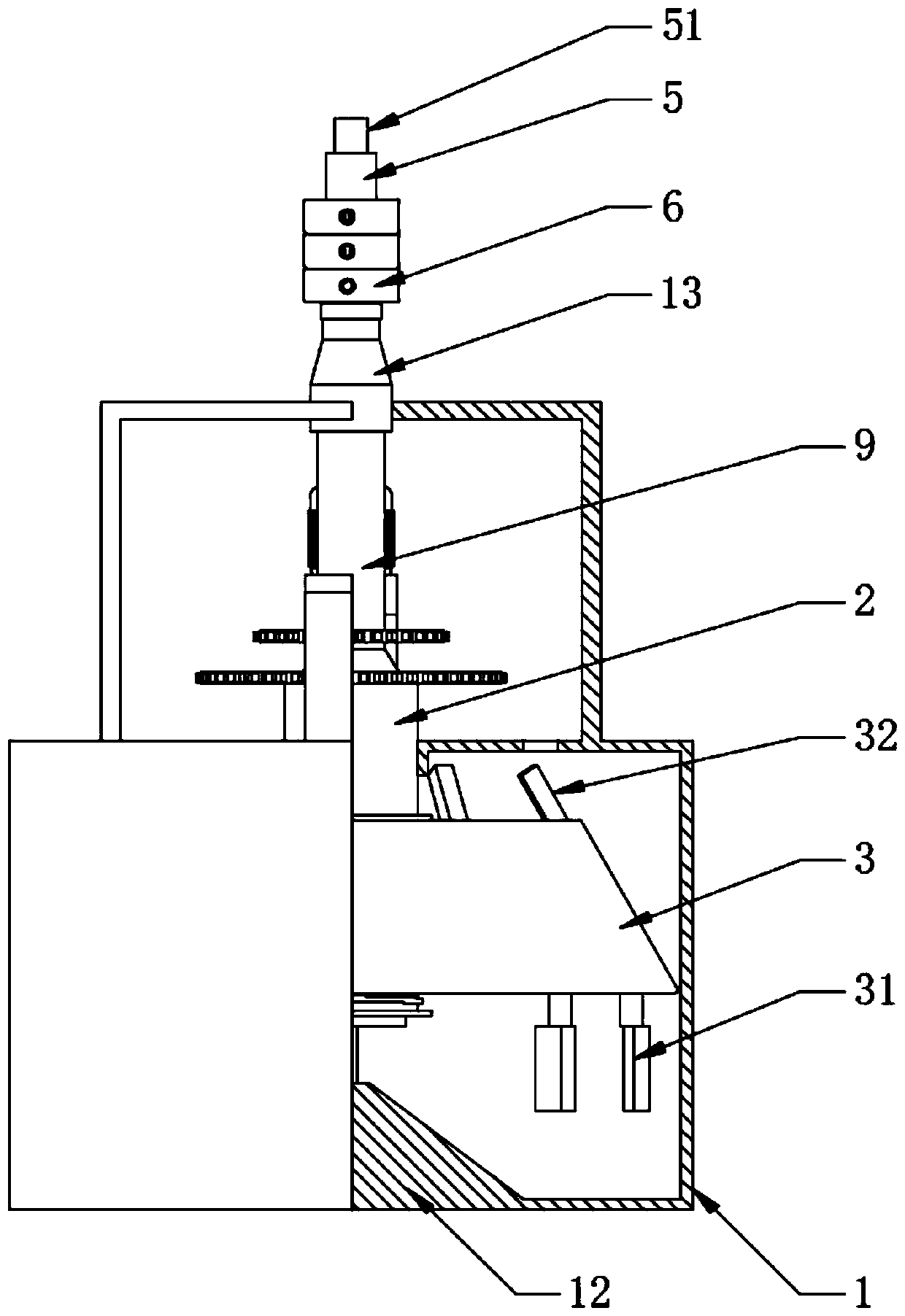

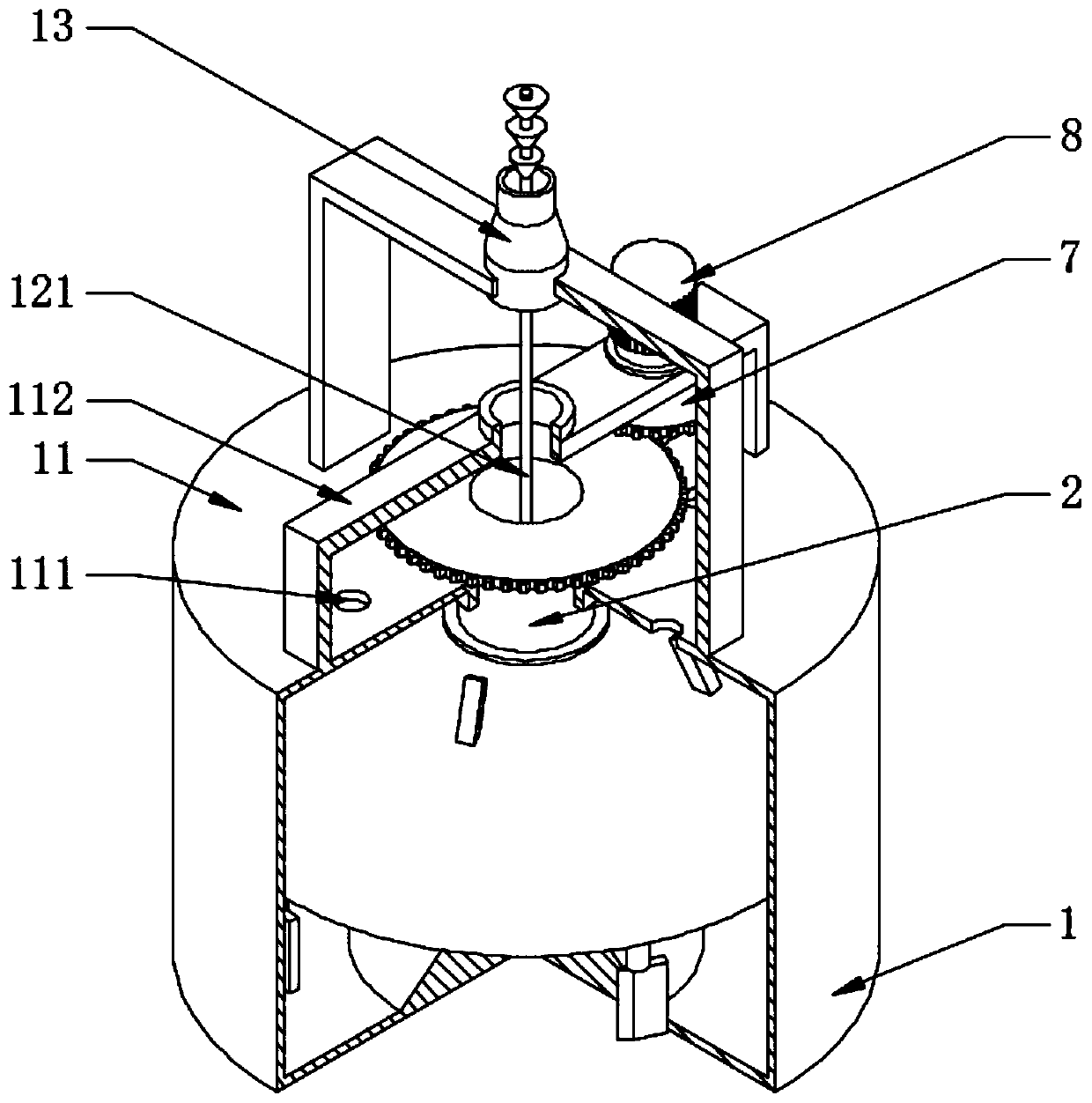

[0036] see Figure 1-8, a high-strength grinder for quantitative analysis of Chinese medicinal materials, comprising a crushing cylinder 1, a rotating sleeve 2, a pressure plate 3, a differential sleeve 9, a return spring 4, a screening tube 5, a collection box 6 set on the screening tube 5, The double-row gear 7 and the negative pressure filter group, the upper cover 11 is arranged on the top of the crushing cylinder 1, the upper cover 11 is provided with an air inlet 111, the rotating sleeve 2 is set on the top of the upper cover 11, and the pressure plate 3 is located The inner and rotating sleeve 2 are connected through the sleeve, and the bottom of the pressure plate 3 is elastically slid in the axial direction with the rotating sleeve 2 through the return spring 4. The top is fixedly connected with a columnar centrifugal drive assembly 32 evenly distributed in the circumferential direction, so that when the rotating sleeve 2 rotates at a high speed, the entire pressure p...

Embodiment 2

[0038] see Figure 6 and Figure 7 The difference from Embodiment 1 is that the differential sleeve 9 is composed of a lower tube 91 located inside the rotary sleeve 2 and an upper tube 92 located outside the rotary sleeve 2, the inner periphery of the lower tube 91 is fixedly connected with a blade 911, and the inner periphery of the upper tube 92 The surface wall is fixedly connected with a spiral deflector 921. Since the deflector column 121 is set in Embodiment 1, the suction of the negative pressure fan will be reduced. The Chinese medicine granules play the role of physical and wind lifting, and the spiral deflector 921 is provided to facilitate the "climbing" of the Chinese medicine granules.

Embodiment 3

[0040] see Figure 7 , and the difference from Example 1 is that the channel 61 and the screening tube 5 are sealed and detachable connections. After the collection box 6 is collected, remove the hose connected to the quick connector 52, and then pull out the collection box 6. The collection box The outer wall of 6 is fixedly connected with a discharge pipe 62 and a filter pipe 63. The function of the filter pipe 63 is to discharge the traditional Chinese medicine with the required particle size. Both the pipe 62 and the filter pipe 63 are screwed together with a cap 64, which is convenient for closing when collecting.

[0041] Working principle: When in use, connect the drive motor 8 and the negative pressure fan to the external control electrical box, and set a feeding door (not shown in the figure) on one side of the crushing cylinder 1, and put hard Chinese medicinal materials into the crushing cylinder 1 Inside, start the driving motor 8, the driving motor 8 drives the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com