Wet mill

A technology of wet mill and ball mill, applied in the field of wet mill, can solve the problems of no automation, high labor intensity and high labor cost, and achieve the effects of increasing slurry temperature control, increasing pressure monitoring in the drum, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

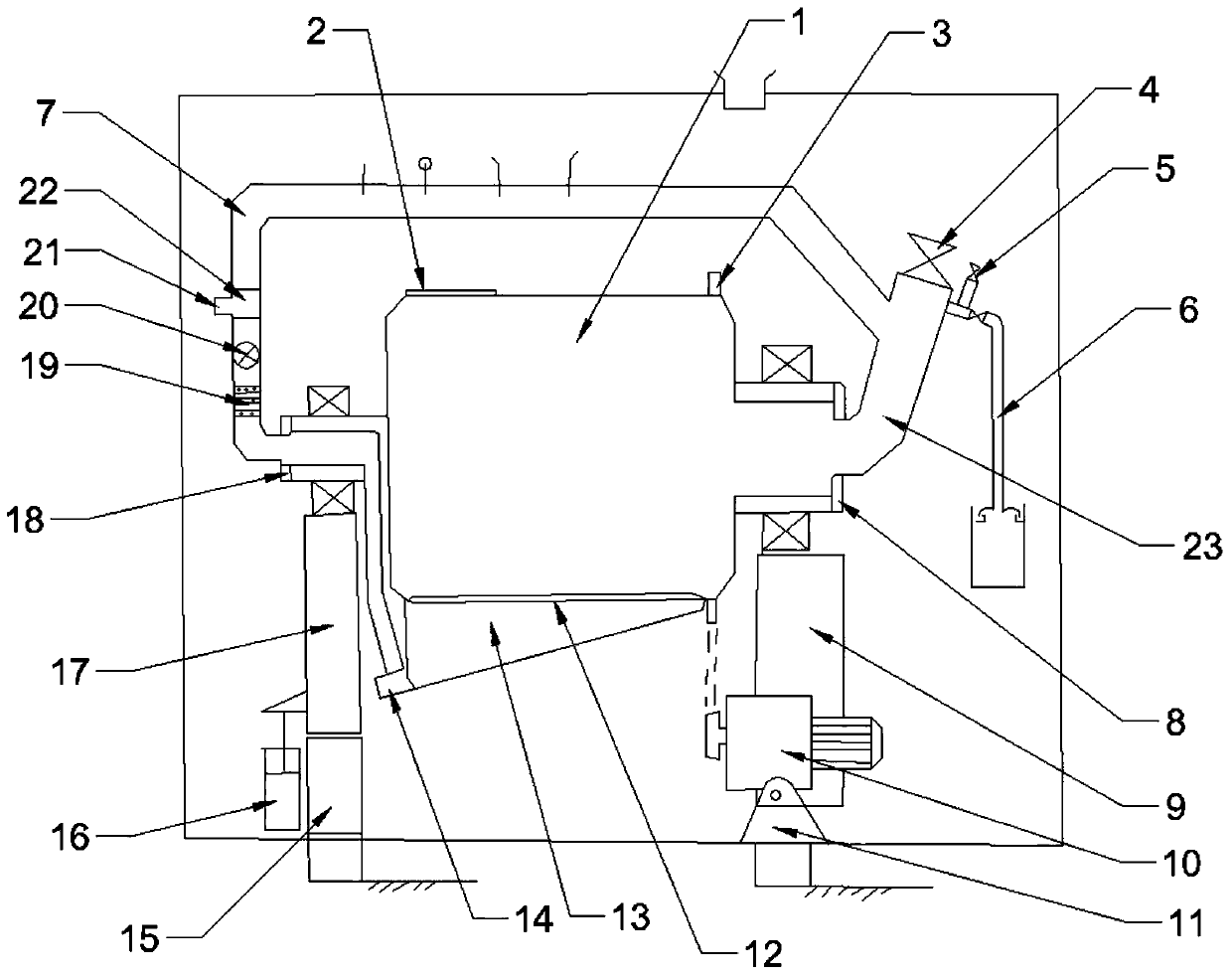

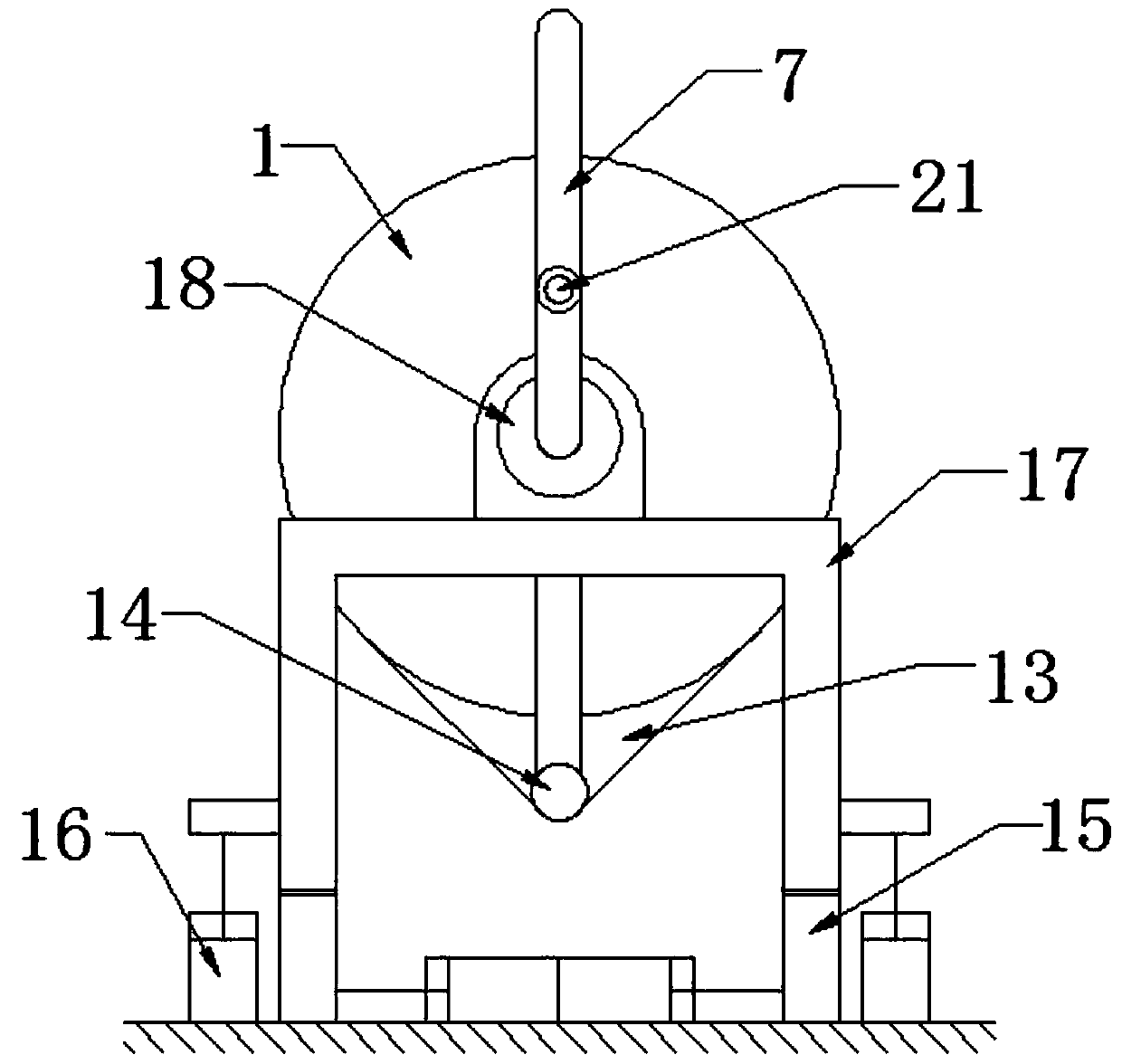

[0023] Such as Figure 1-2 As shown, a wet mill includes a ball mill cylinder 1, the upper part of the ball mill cylinder 1 is provided with a ball outlet 2, the surface of the ball mill cylinder 1 is fixedly sleeved with a sprocket 3 and is connected to the motor 10 through a transmission chain, and the lower part of the ball mill cylinder 1 There is an inclined bucket 13, and the bottom of the inclined bucket 13 is provided with a slagging outlet 14, and the inner lower end of the ball mill cylinder 1 is also equipped with a ball grid 12, which is located between the ball mill cylinder 1 and the inclined bucket 13 and is connected to the ball mill. Cylinder 1 and inclined bucket 13, the cylinder mouth of ball mill cylinder 1 is connected with feed pipe 23, the end of feed pipe 23 away from ball mill cylinder 1 is feed inlet 4 and is provided with feed valve, and feed pipe 23 is far away from ball mill cylinder 1 The two sides are respectively connected with the circulation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com