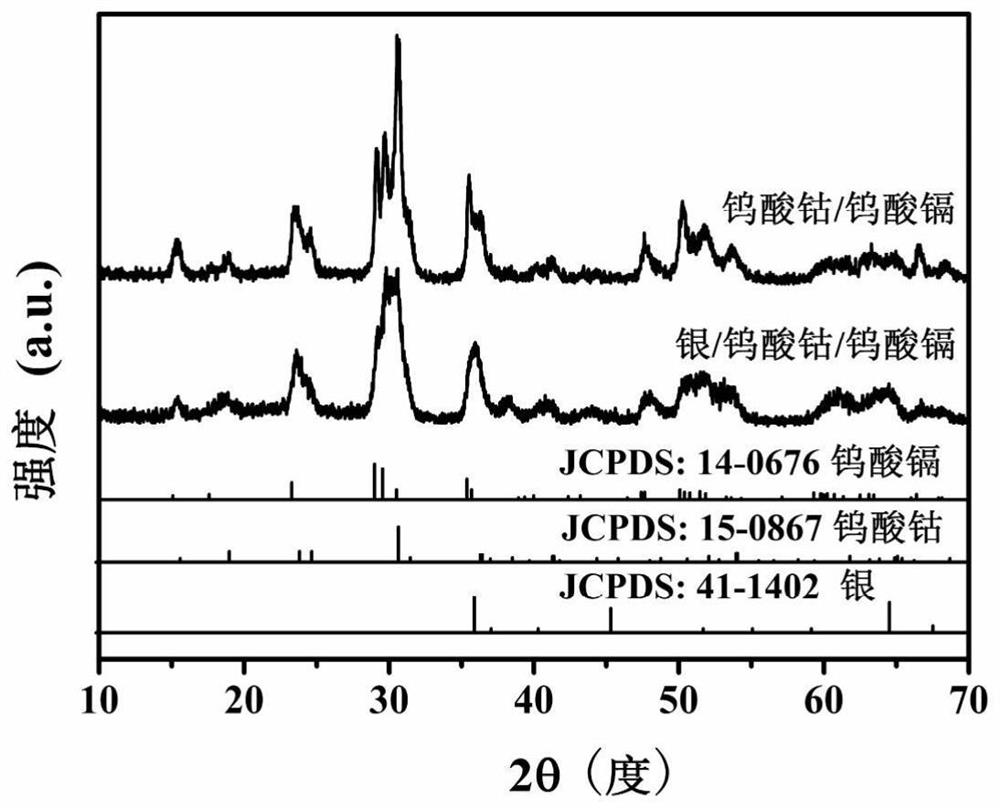

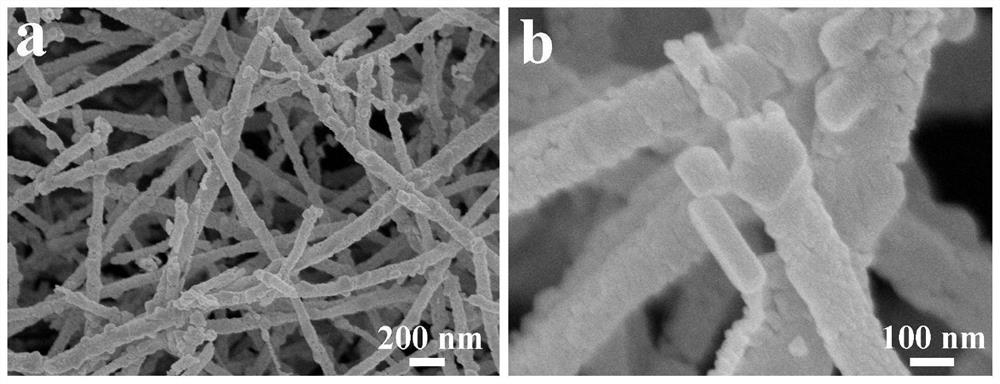

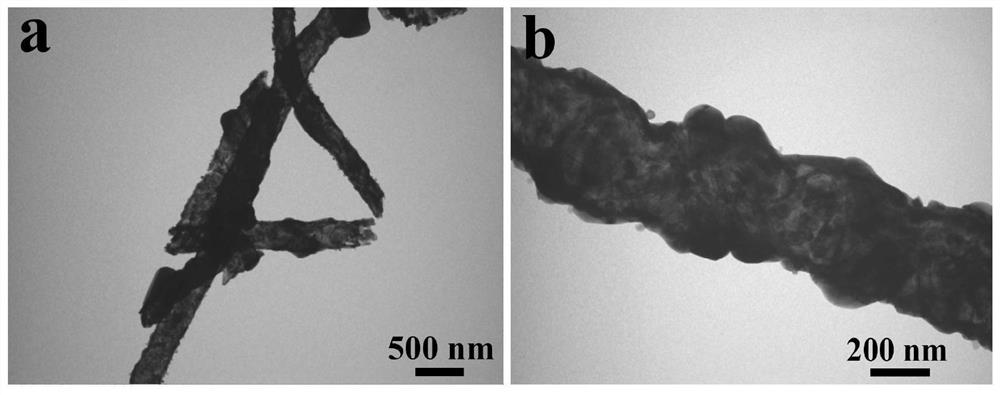

A silver-modified cobalt tungstate/cadmium tungstate nanofiber photocatalytic material and its preparation method and application

A technology of photocatalytic materials and nanofibers, applied in the field of photocatalytic materials, can solve the problems of unfavorable photogenerated carrier transmission and separation, high application cost, difficult recycling and reuse, etc., to avoid thermodynamic instability, uniform distribution, The effect of preventing cluster aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A silver-modified cadmium tungstate / cobalt tungstate (Ag / CoWO) 4 / CdWO 4 ) The preparation method of composite nanofiber photocatalytic material, including steps are as follows:

[0067] (1) Preparation of spinnable precursor sol: 0.7391 g (W: 3 mmol) ammonium metatungstate, 0.2665 g (Cd: 1 mmol) cadmium acetate and 0.9046 g (Co: 2 mmol) cobalt nitrate were dissolved in 3 mL methanol and 7 mL In a mixed solvent composed of N,N-dimethylformamide, stir until completely dissolved, add 0.8g of polyvinylpyrrolidone (PVP), stir evenly, and obtain a spinnable precursor sol with a viscosity of 0.5Pa·S;

[0068] (2) CoWO 4 / CdWO 4 Preparation of precursor fibers: The spinnable precursor sol was sprayed into the receiver plate with a plastic syringe with a stainless steel needle, and the receiving distance between the stainless steel needle of the syringe and the receiver plate was 15 cm, and the spinnable precursor sol was sprayed The rate was 1.5 mL / h, the voltage was 20 kV, ...

Embodiment 2

[0074] A silver-modified cadmium tungstate / cobalt tungstate (Ag / CoWO) 4 / CdWO 4 ) The preparation method of composite nanofiber photocatalytic material, including steps are as follows:

[0075] (1) Preparation of spinnable precursor sol: 0.7391 g (W: 3 mmol) ammonium metatungstate, 0.2665 g (Cd: 1 mmol) cadmium acetate and 0.9046 g (Co: 2 mmol) cobalt nitrate were dissolved in 3 mL methanol and 7 mL In a mixed solvent composed of N,N-dimethylformamide, stir until completely dissolved, add 0.8g of polyvinylpyrrolidone (PVP), stir evenly, and obtain a spinnable precursor sol with a viscosity of 0.5Pa·S;

[0076] (2) CoWO 4 / CdWO 4 Preparation of precursor fibers: The spinnable precursor sol was sprayed into the receiver plate with a plastic syringe with a stainless steel needle, and the receiving distance between the stainless steel needle of the syringe and the receiver plate was 25 cm, and the spinnable precursor sol was sprayed The rate was 1.5 mL / h, the voltage was 30 kV...

Embodiment 3

[0081] A silver-modified cadmium tungstate / cobalt tungstate (Ag / CoWO) 4 / CdWO 4 ) The preparation method of composite nanofiber photocatalytic material, including steps are as follows:

[0082] (1) Preparation of spinnable precursor sol: 0.6159 g (W: 2.5 mmol) ammonium metatungstate, 0.2665 g (Cd: 1 mmol) cadmium acetate and 0.6784 (Co: 1.5 mmol) cobalt nitrate were dissolved in 3 mL of anhydrous In a mixed solvent composed of ethanol and 7mL of N,N-dimethylformamide, stir until completely dissolved, add 1.2g of polyvinylpyrrolidone (PVP), stir evenly, and obtain a spinnable precursor sol with a viscosity of 0.7Pa·S ;

[0083] (2) CoWO 4 / CdWO 4 Preparation of precursor fibers: The spinnable precursor sol was sprayed into the receiver plate with a plastic syringe with a stainless steel needle, and the receiving distance between the stainless steel needle of the syringe and the receiver plate was 25 cm, and the spinnable precursor sol was sprayed The rate was 1.5 mL / h, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com