Cuttable Fibula reconstruction jaw defect model and manufacturing method and application thereof

A method of making, technology of fibula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

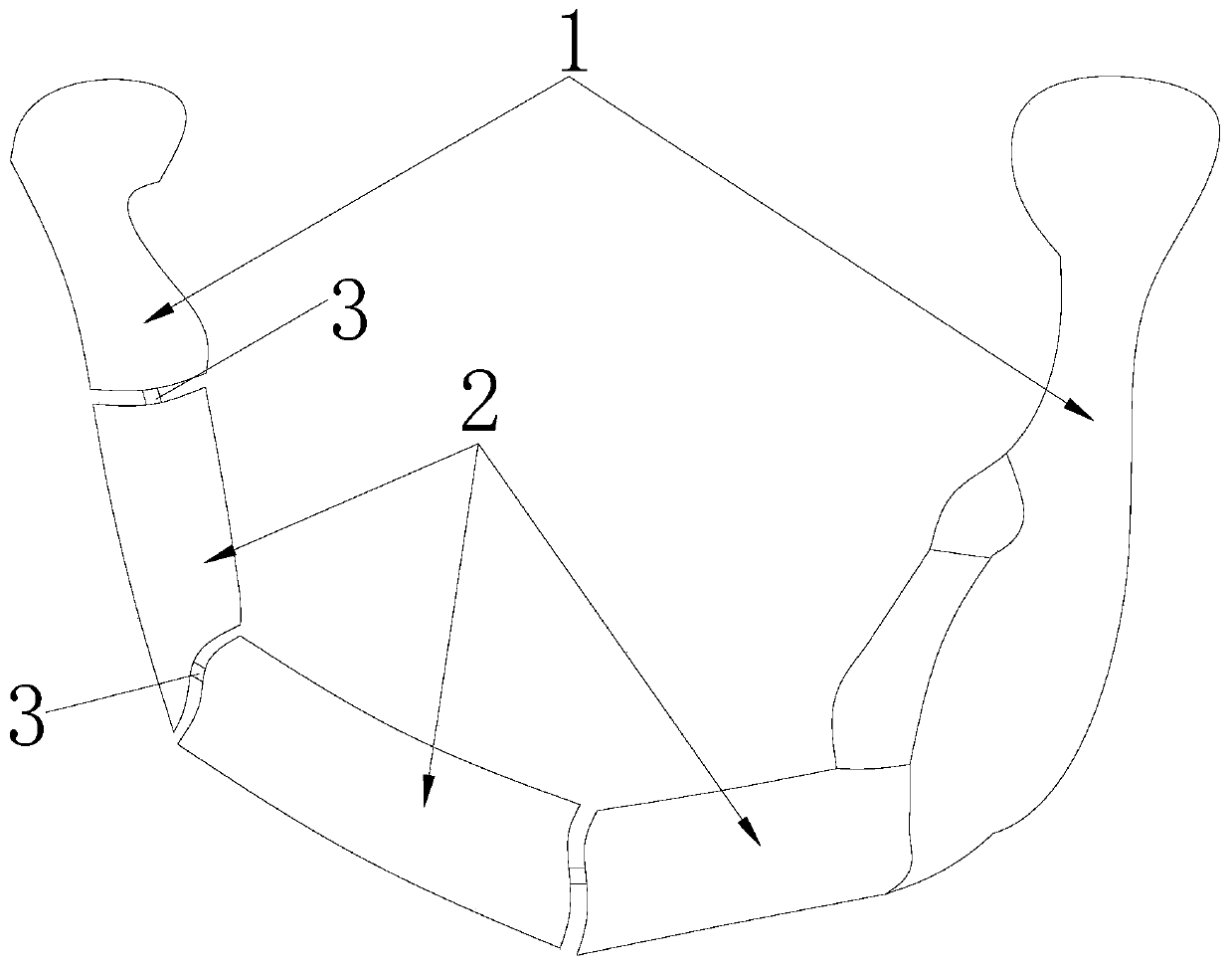

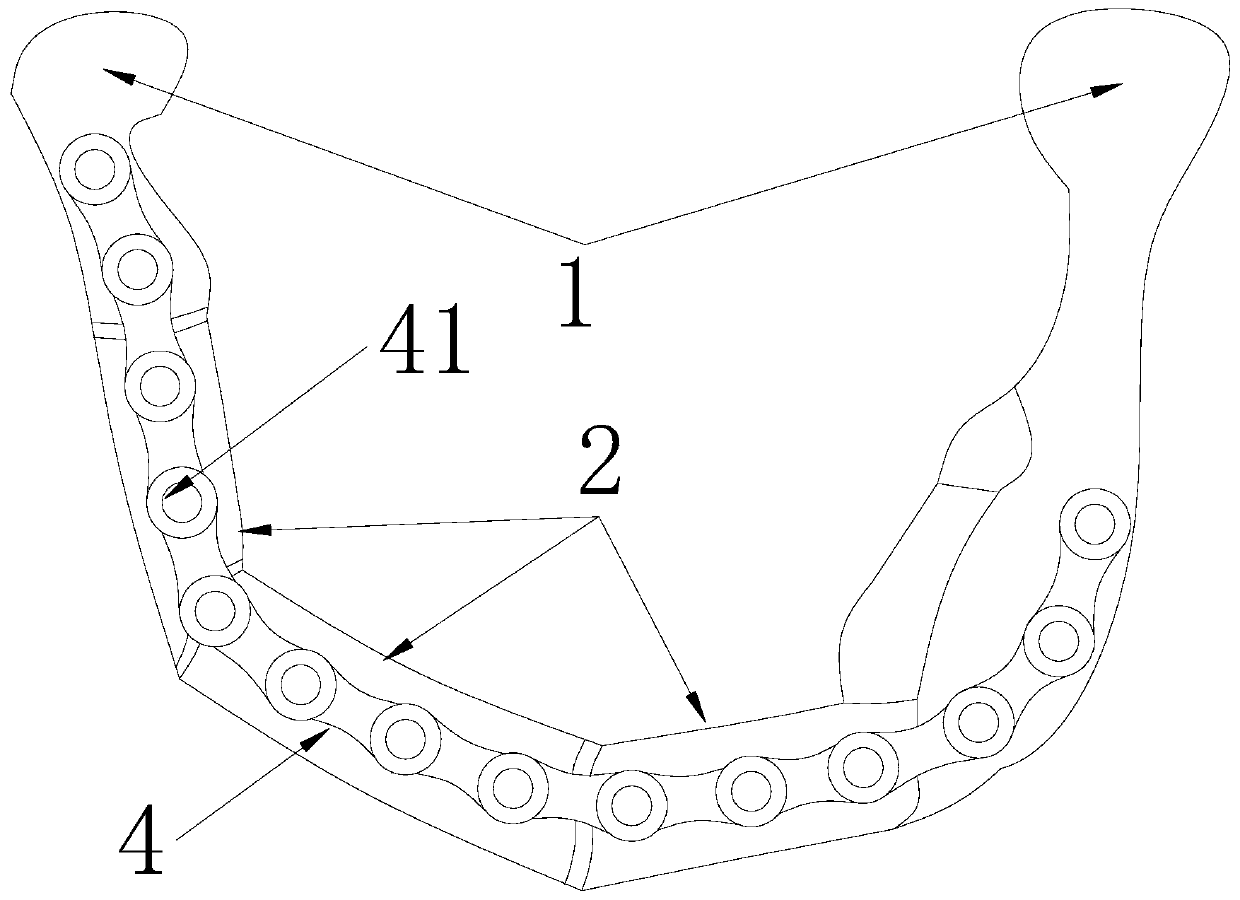

[0031] A fractured fibula model for reconstruction of jaw defects, see appendix figure 1 As shown, it includes a jaw model body 1 and a fibula model body 2, and the jaw model body 1 and fibula model body 2 are connected through a connecting column 3 to form a complete fibula that can be cut off to reconstruct a jaw defect model.

[0032] Further, the mandibular model body 1, the fibula model body 2 and the connecting column 3 are formed by 3D printing.

[0033] Further, the mandibular model body 1, the fibula model body 2 and the connecting column 3 are made of medical resin.

[0034] A model capable of truncating fibula to reconstruct a jaw defect, the manufacturing method comprising the following steps:

[0035] S1. Use CT scanning equipment to perform head CT and double lower limb CTA examinations on patients with jaw lesions, and import the DICOM data of the scanned imaging data into medical software to reconstruct a complete jaw simulation model and fibula simulation mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com