Nondestructive detection device for boiler pressure vessel pipeline

A non-destructive detection and boiler pressure technology, which is applied in pipeline systems, supporting machines, gas/liquid distribution and storage, etc., can solve the problems of point-like distribution detection and continuous detection, and achieve no leak point detection cost, cost saving, The effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

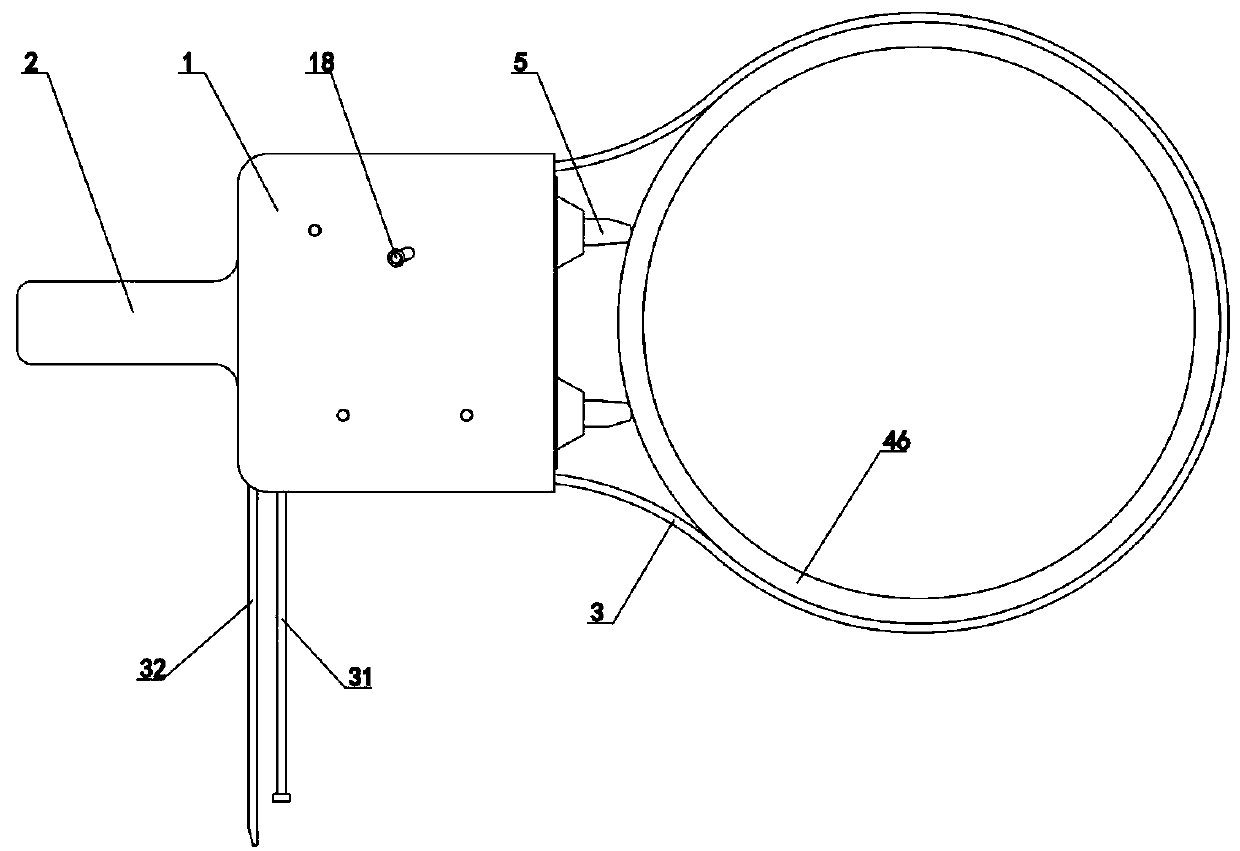

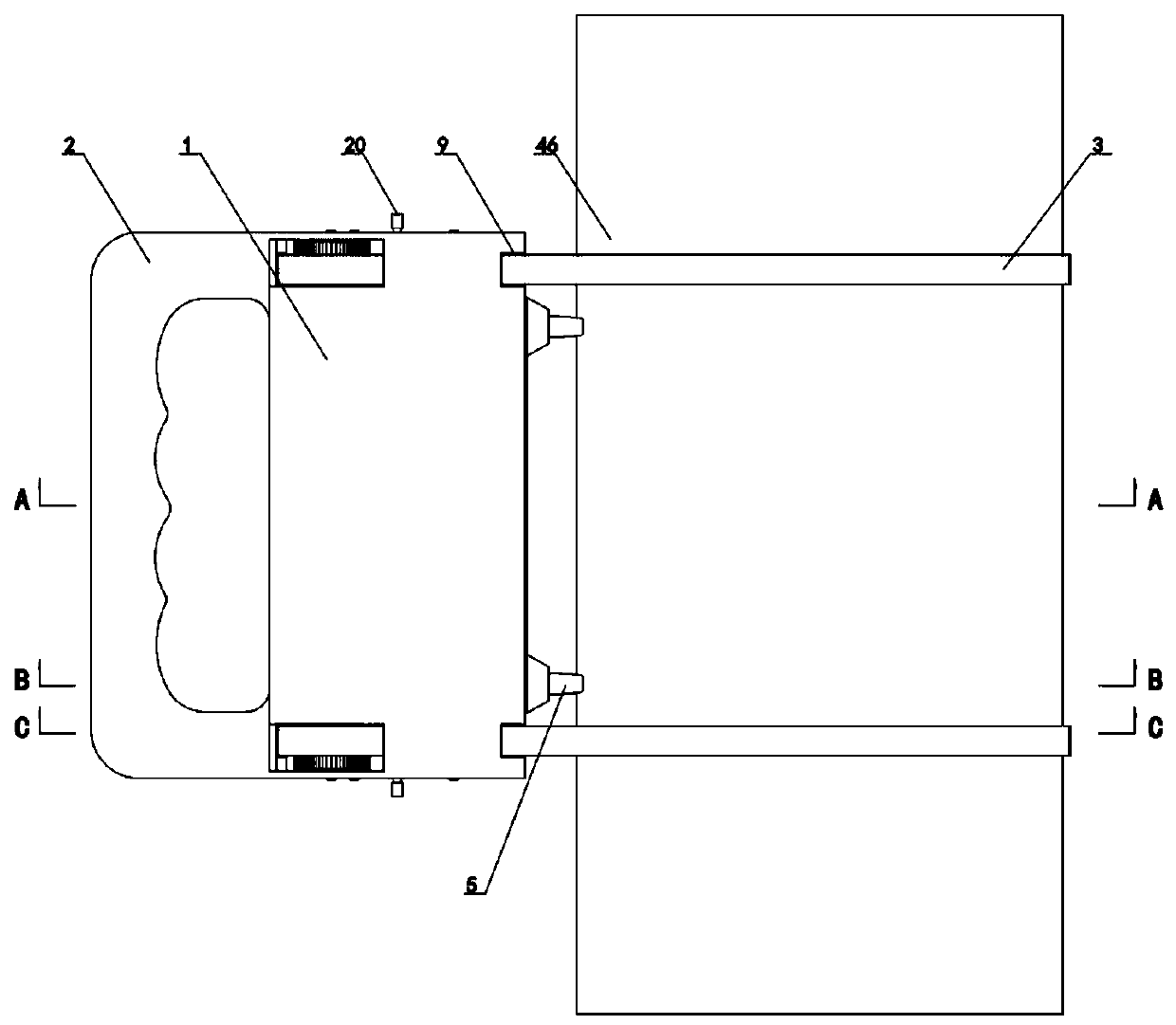

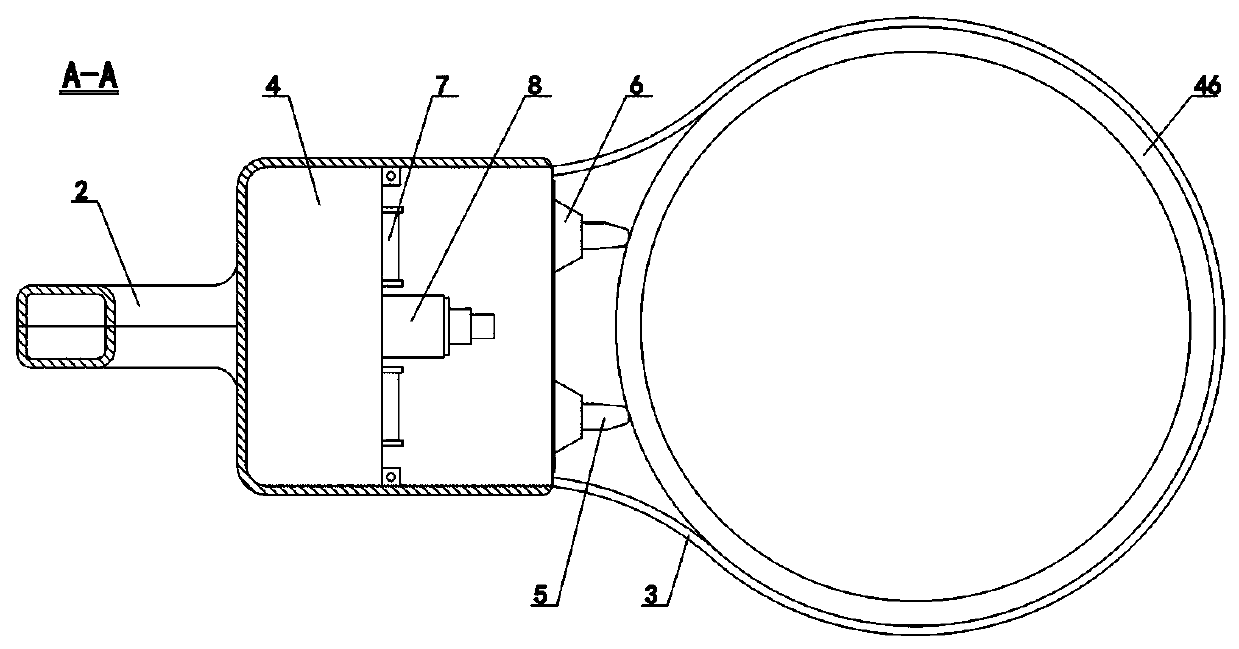

[0031] Example 1: One such as figure 1 The shown magnetic particle nondestructive detection device for pressure pipelines is mainly used in the nondestructive detection process of boilers and pressure vessel pipelines. figure 1 with figure 2 It can be seen that the device mainly includes a casing 1, a handle 2, a gear belt 3, a magnetic particle detector main body 4, a metal yoke column 5, a searchlight 7, and a power supply 22. The handle 2 is located on the back side of the casing 1, the main body 4 of the magnetic particle detector is located inside the casing, the metal yoke column 5 fixedly connected on both sides of the main body 4 of the magnetic particle detector is exposed outside the casing, and the searchlight 7 is fixed on both sides of the metal On the housing of the yoke column 5 bracket.

[0032] by figure 2 It can be seen that the crawler belt 3 is located at symmetrical positions on both sides of the casing. When the crawler belt 3 is set on the outside of the p...

Embodiment 2

[0040] Embodiment 2: On the basis of embodiment 1, the magnetic field part of the device is further provided, so that the ends of each metal yoke column are respectively installed with metal rollers 25 through the metal wheel base 44 and the shaft, and the metal rollers 25 are supported on the outer wall of the pressure pipe . The magnetism of the metal yoke column is transmitted to the outer side wall of the pressure pipe 46 through the metal wheel base 44 and the metal roller 25, and the rotation flexibility of the device can be improved by the metal roller 25.

Embodiment 3

[0041] Embodiment 3: On the basis of implementation 1, a powder sprayer is installed on the outside of the casing or in the detection area of the casing. The powder sprayer includes a magnetic powder chamber 26 and an air pressure chamber 27. The air pressure chamber 27 is a equal diameter cylinder A piston 28 is fitted in a matching suit. The air pressure chamber 27 has an inlet at the head end, and the end is connected to the magnetic powder chamber 26 through a filter layer 29. The magnetic powder chamber 26 is provided with a powder filling port and a spray head 30. The powder sprayer also includes a booster tank 33. The booster tank 33 is provided with a pressure injection nozzle and an outlet. The outlet is in closed communication with the inlet of the air pressure chamber 27 through the solenoid valve 34 and the air pressure pipe 35.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com