Continuous carbonization and pyrolysis treatment method of waste lithium battery

A technology for waste lithium batteries and a disposal method is applied in the field of continuous carbonization and pyrolysis disposal of waste lithium batteries, which can solve problems such as ineffective recycling, and achieve the effects of improving the utilization efficiency of combustion heat energy, reducing the probability of oxidation, and reducing the generation of harmful substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

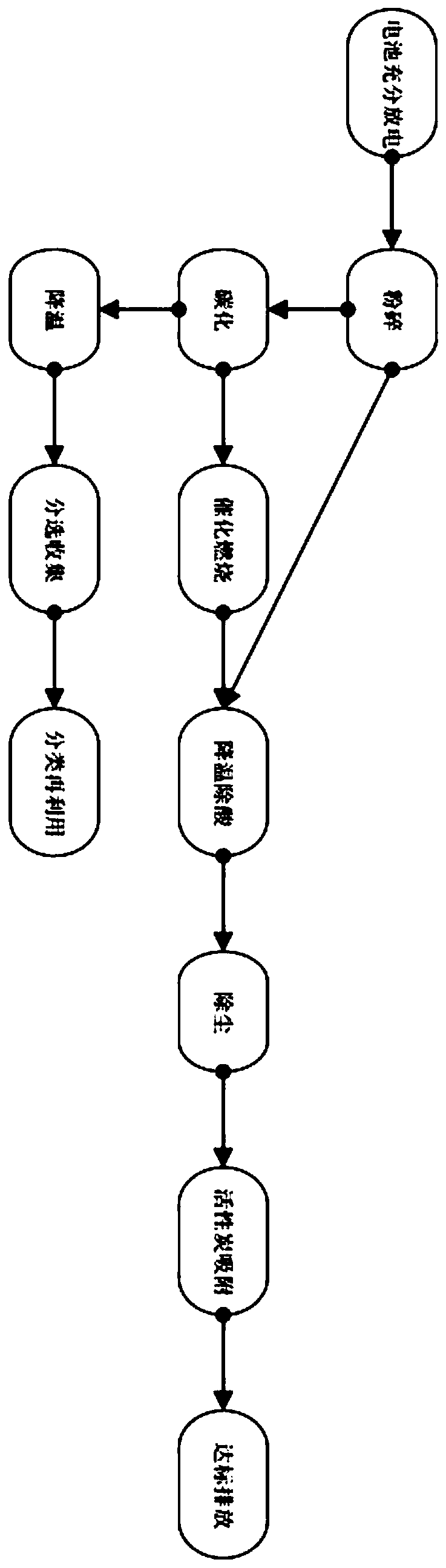

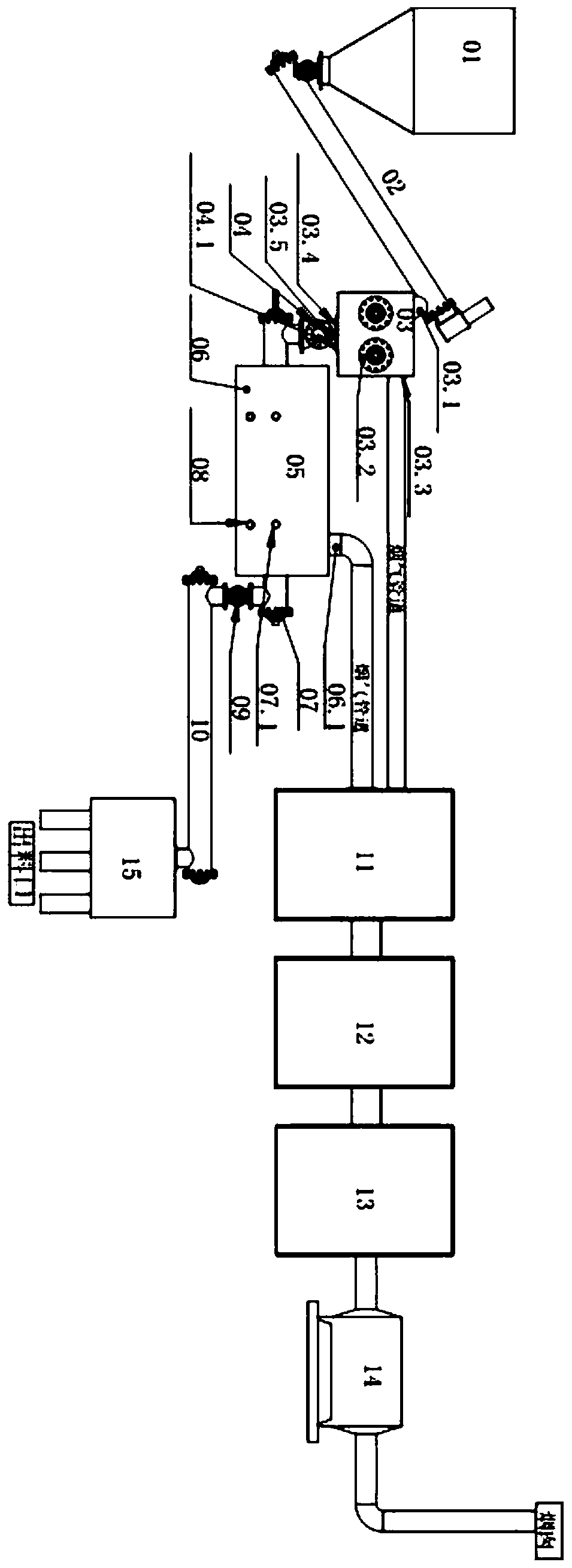

[0051] A continuous carbonization and pyrolysis treatment method for waste lithium batteries adopts the following treatment process:

[0052] The first step: preheating, that is, preheating the carbonization equipment 05 to the working temperature, usually the temperature in the furnace is set at 500-700°C;

[0053] The second step: pretreatment, including two steps, that is, lithium battery discharge and crushing. First, the lithium battery must be fully discharged (if it is a lithium battery pack, you can choose to disassemble the battery first, together with the battery pack shell), and put it into The temporary storage tank 01 enters the closed pulverizer 03 through a closed or semi-closed conveying device 02, which can be selected from shaftless screw or belt transportation. After pulverization, the mixed material enters the carbonization chamber 07 of the carbonization equipment 05 through the feed valve 04;

[0054] Step 3: Carbonization and pyrolysis treatment process....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com