Self-adhesive antibacterial silicone rubber and preparation method thereof

A silicone rubber and self-adhesive technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of biological fouling of materials, high requirements for adhesives, and cumbersome processing procedures and other issues, to achieve long-lasting antibacterial properties, excellent comprehensive performance, and good product performance control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of self-adhesive antibacterial silicone rubber, its formula composition is by weight:

[0037] 90 parts of antibacterial base material and 10 parts of methyl hydrogen polysiloxane composed of 100 parts of antibacterial silicone rubber, with a specific surface area of 150m after surface treatment with hexamethyldisilazane 2 / g of fumed silica 35 parts, hydroxyl content 8%, viscosity 10mm at 25°C 2 / s of 5 parts of hydroxy silicone oil, 1 part of dicumyl peroxide, 3 parts of flame retardant composed of triphenyl phosphate and decabromodiphenyl ether in a weight ratio of 3:1, and four parts in a weight ratio of 3:1 1 part of antioxidant composed of [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and diester of thiodipropionate;

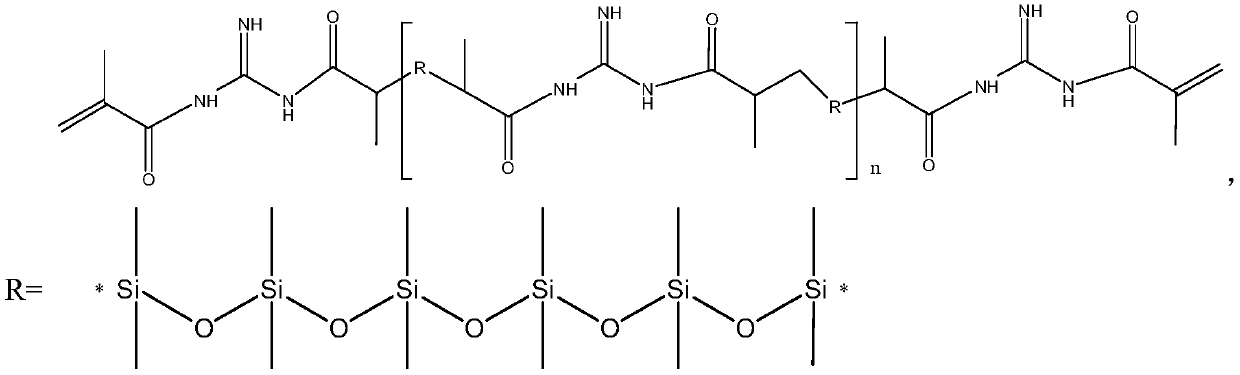

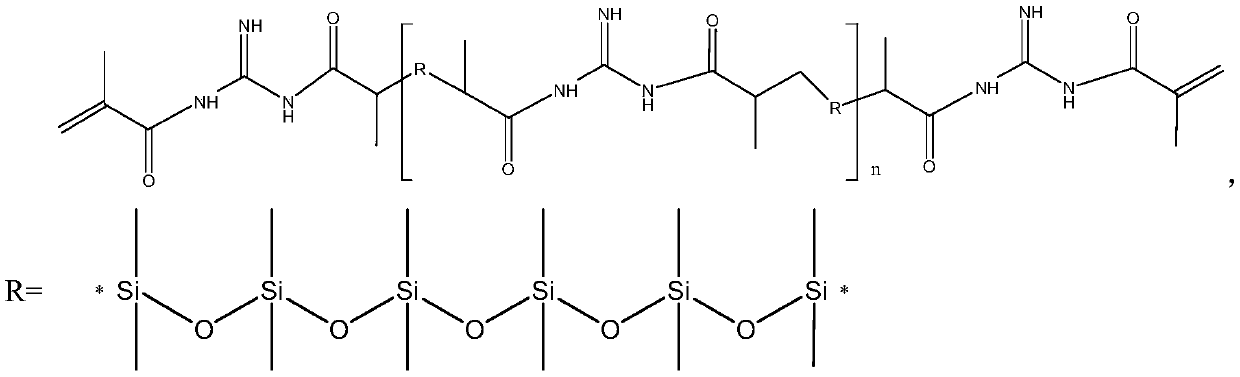

[0038] The antibacterial base material is composed of 70 parts of guanidine-containing antibacterial polymer, 60 parts of α, ω-divinyl polydimethylsiloxane, and 0.5 part of boric acid.

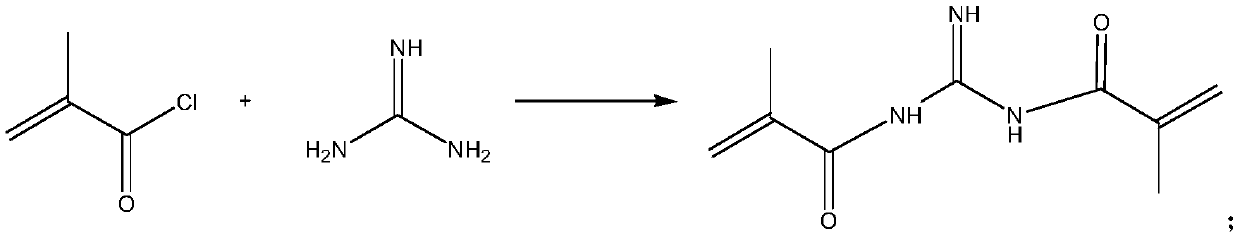

[0039] Described guanid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com