Premixed mortar for green building and building construction method using mortar

A ready-mixed mortar and green building technology, applied in the field of building construction, can solve the problems of broken glass, troublesome, and high cost of waste glass, and achieve the effects of improving impermeability, avoiding costs, and achieving good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

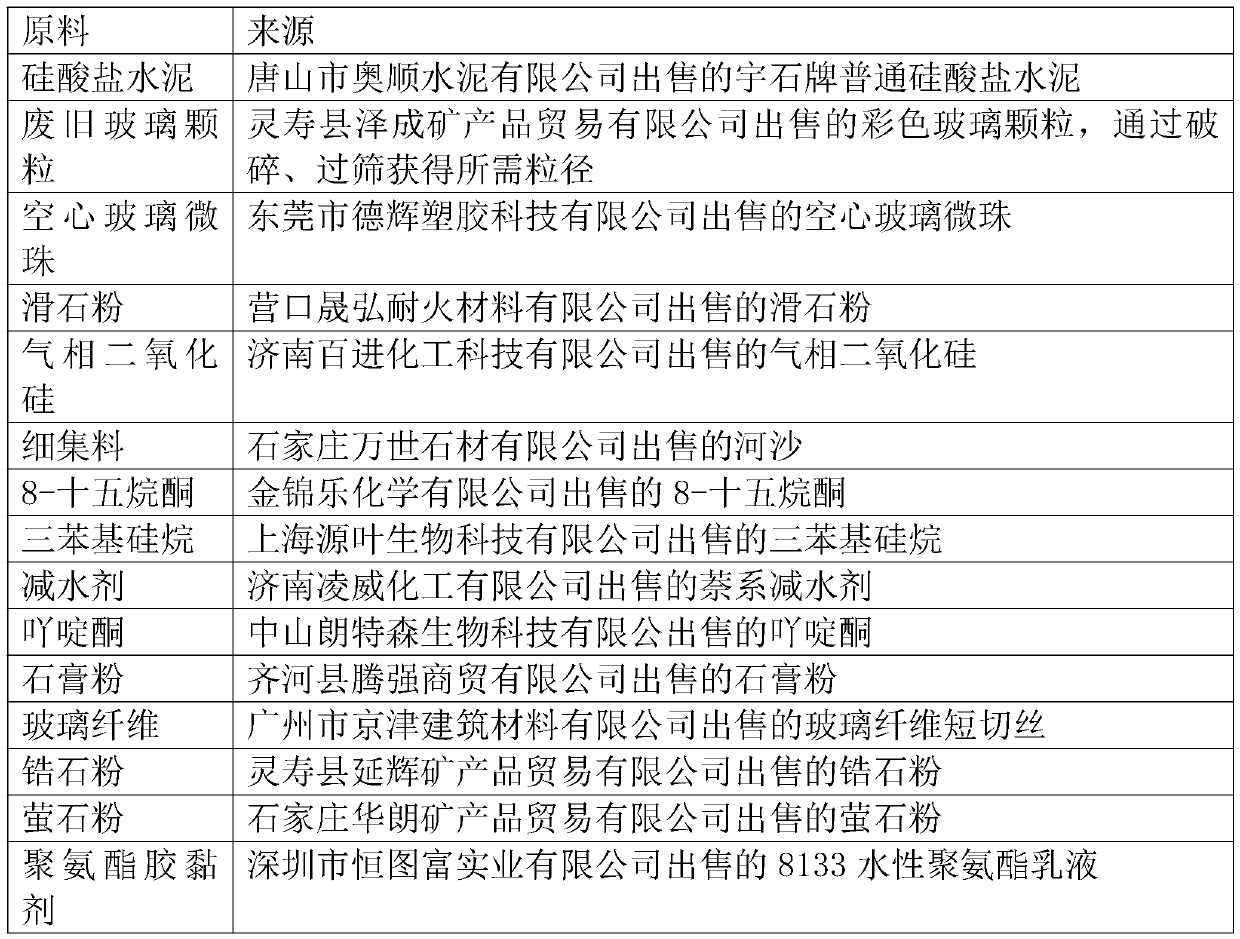

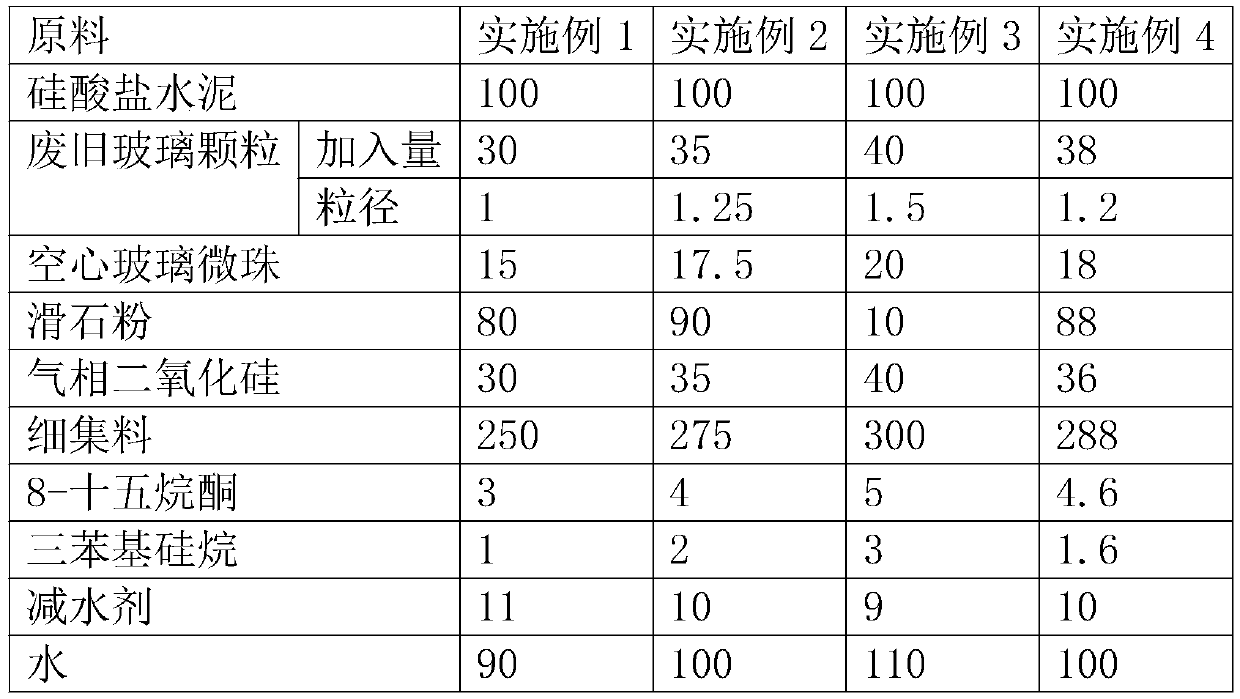

[0067] A green building ready-mixed mortar, comprising the following raw materials:

[0068] Portland cement, waste glass particles, hollow glass microspheres, talcum powder, fumed silica, fine aggregate, 8-pentadecanone, triphenylsilane, water reducer, water.

[0069] The specific addition amount (unit is Kg) of each raw material in each embodiment and the particle diameter (unit is mm) of waste glass particle see table 2 for details:

[0070] Table 2

[0071]

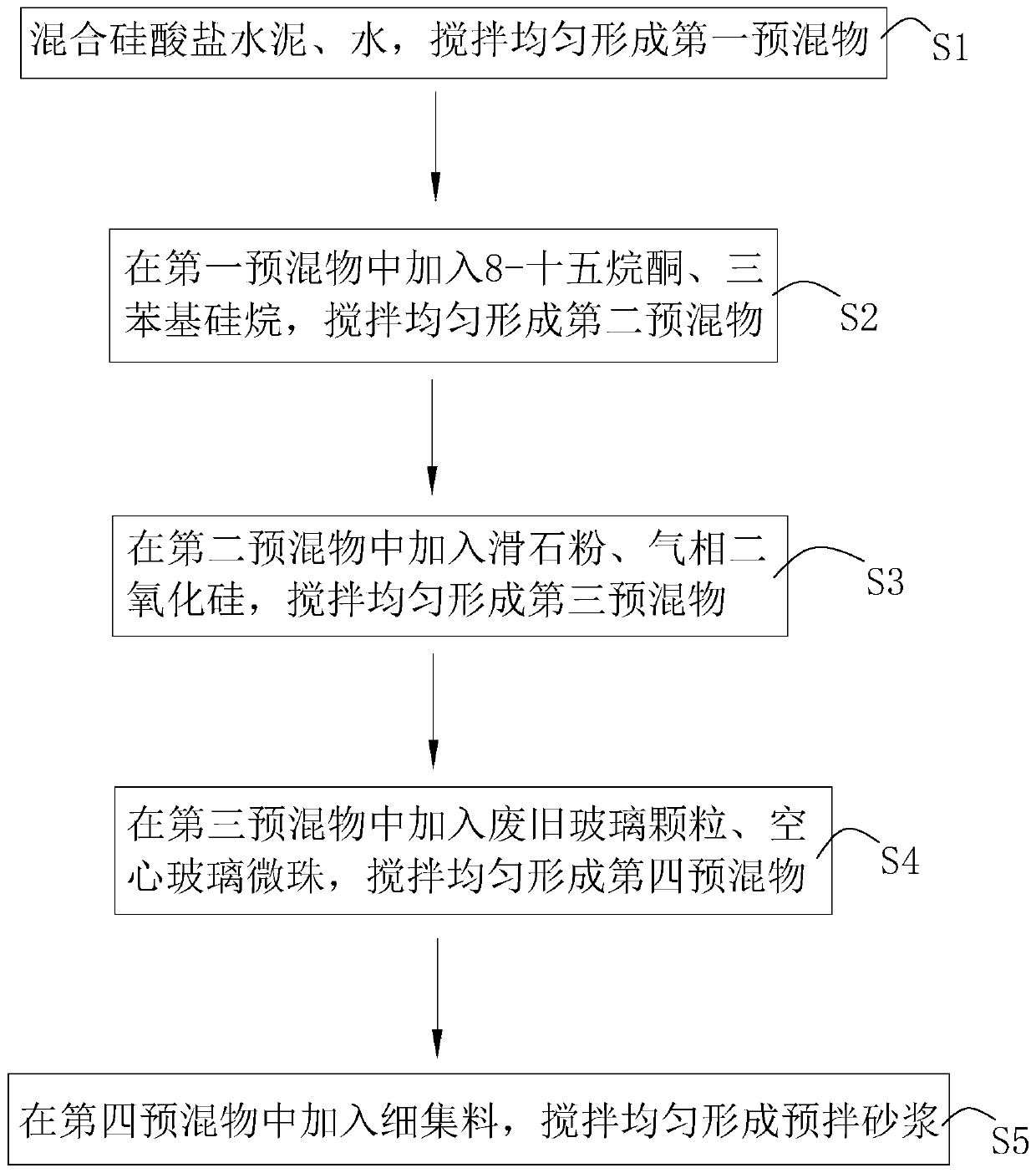

[0072] refer to figure 1 , the preparation method of the green building of embodiment 1-4 specifically comprises the following steps:

[0073] S1. Add Portland cement, water, and water reducer to the stirring tank at a speed of 80r / min, and stir for 3min to form the first premix;

[0074] S2. Add 8-pentadecanone and triphenylsilane to the first premix, rotate at 80r / min, and stir for 3min to form the second premix;

[0075] S3. Add talcum powder and fumed silica to the second premix, rotate at a speed of 60r / mi...

Embodiment 5-8

[0079] Compared with embodiment 4, the difference only lies in:

[0080] Acridone is also added in step S2, and the specific addition amount (unit is Kg) of each raw material in each embodiment is detailed in Table 3:

[0081] table 3

[0082] raw material Example 5 Example 6 Example 7 Example 8 Acridone 0.5 0.65 0.8 0.7

Embodiment 9-12

[0084] Compared with embodiment 4, the difference only lies in:

[0085] Also add gypsum powder in step S2, the specific addition amount (unit is Kg) of each raw material in each embodiment sees Table 4 for details:

[0086] Table 4

[0087] raw material Example 9 Example 10 Example 11 Example 12 Gypsum powder 2 3 4 2.8

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com