Wire stripping and bending device for electrical engineering

A technology of electrical engineering and bending devices, which is applied to the installation of cable installation devices, electrical components, cables, etc., can solve the problems of easily damaged wire cores, time-consuming and labor-intensive manual operations, labor-intensive manual bending, etc., to reduce sliding resistance, Prevents damage to the core and improves productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

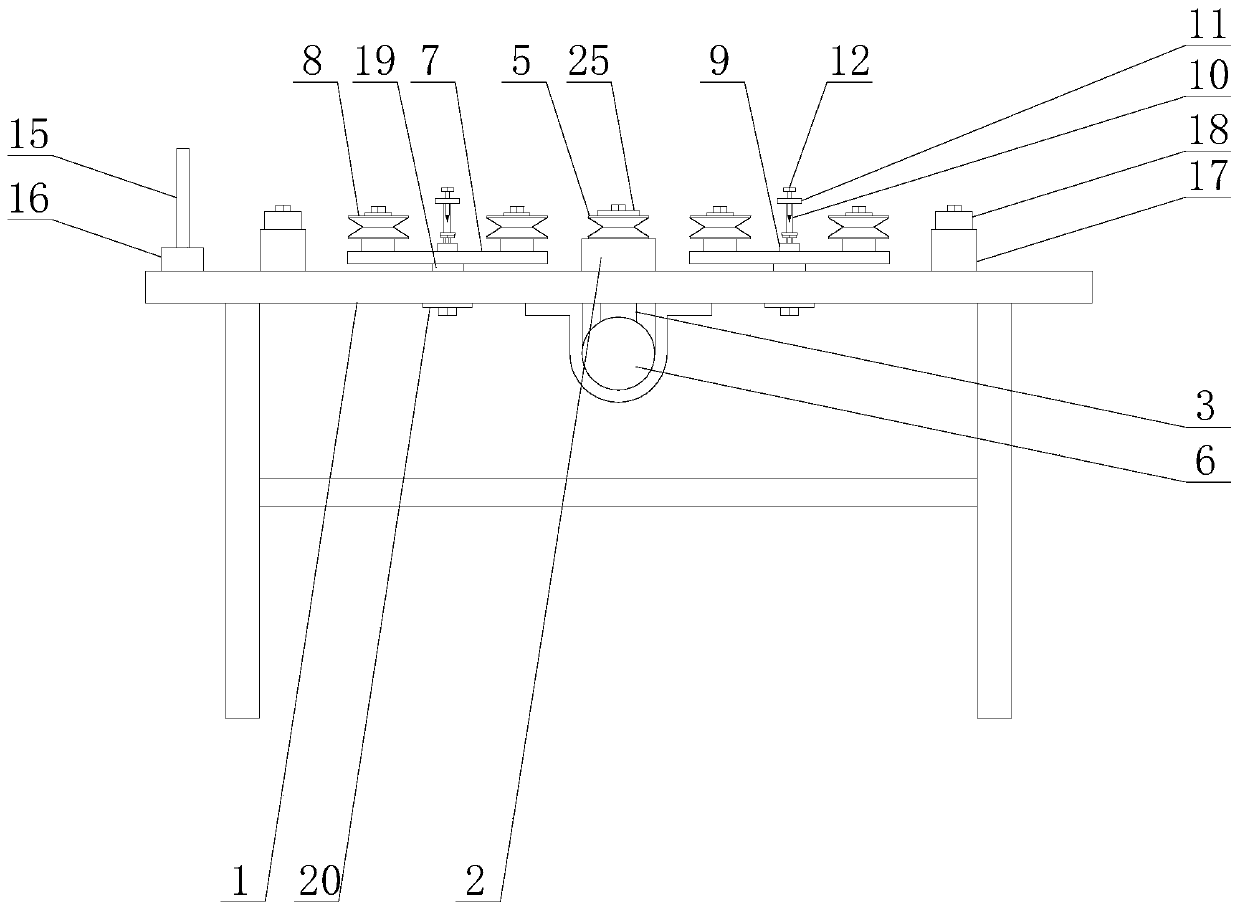

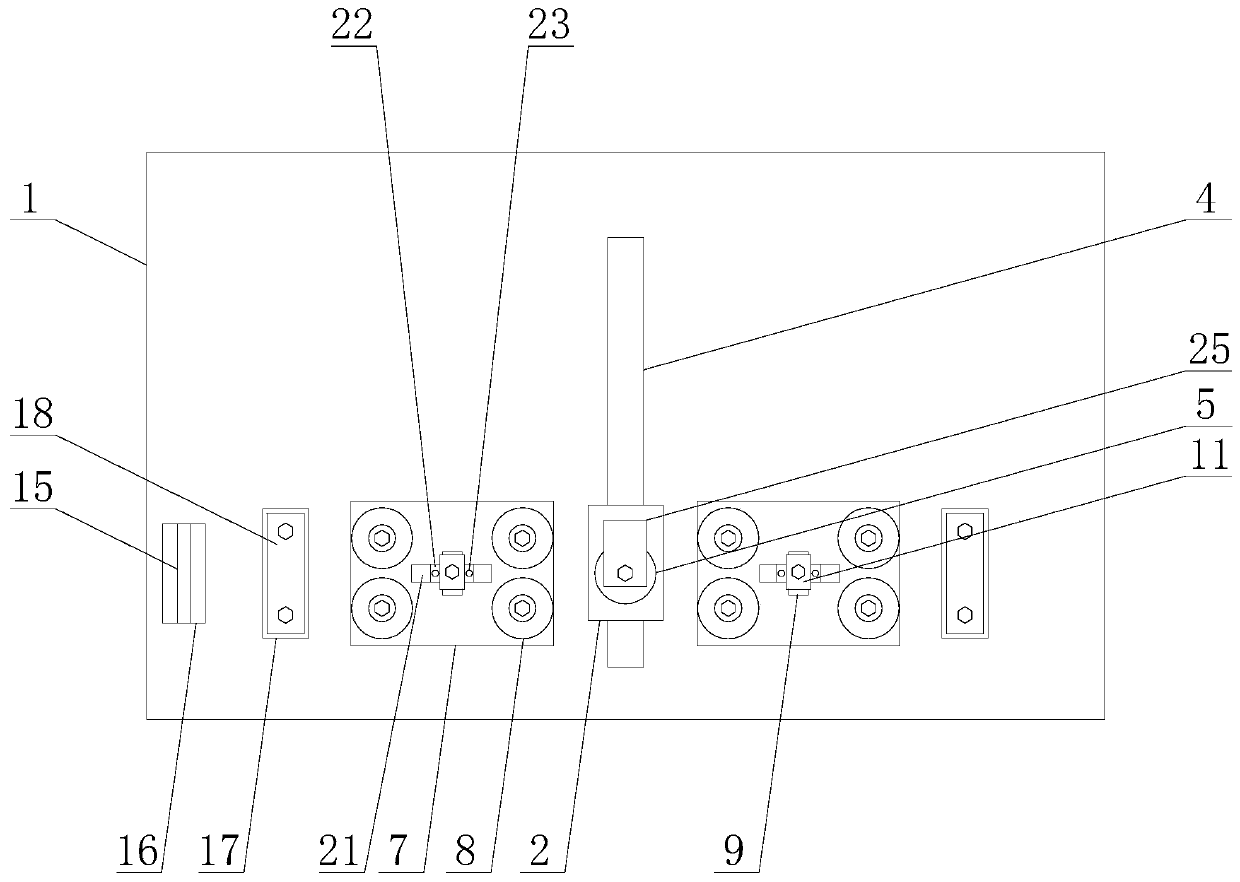

[0020] Embodiment 1: as attached Figure 1-3 As shown, the present invention is a wire stripping and bending device for electrical engineering, which includes a workbench 1, and the workbench 1 is composed of an iron plate and four supporting legs welded at the bottom of the iron plate. The top of the workbench 1 is provided with a base 2, the bottom of the base 2 is provided with a slide block 3, and the middle part of the workbench 1 is provided with a chute 4 adapted to the slide block 3, and the base 2 can move along the chute. 4 slide, and the chute 4 is a rectangular hole offered on the iron plate. After the end of the slide block 3 away from the base 2 is inserted in the chute 4, it is positioned at the lower side of the iron plate. The top of described base 2 is equipped with first V-shaped wheel 5, and the bottom of described workbench 1 is provided with cylinder 6, and the length direction of described cylinder 6 is parallel with the length direction of chute 4, and ...

Embodiment 2

[0022] Embodiment 2: On the basis of Embodiment 1, in order to ensure the bending size requirements, one of the support plates 7 is provided with a positioning plate 15 on the side away from the chute 4, and the bottom of the positioning plate 15 is provided with a magnetic force Seat 16 utilizes the suction between the magnetic base 16 and the iron plate to fix the position of the positioning plate 15. After the positioning plate 15 is adjusted to a suitable position, the V-shaped wheel group 8 on the support plate 7 of the positioning plate 15 is used as At the starting point, the wires are sequentially passed through and then abutted against the positioning plate 15 for processing and positioning to ensure that the bending meets the size requirements. In order to straighten the bent wire to ensure the bending quality, a V-shaped block 17 is provided on the side of the support plate 7 away from the chute 4, and the V-shaped block 17 is rotatably connected with the workbench 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com