Preparation method and application of vertically-oriented magnetic nanosheet/sodium alginate composite membrane

A magnetic nanometer and sodium alginate technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of inability to significantly improve membrane permeability, large flow resistance, and long mass transfer path, etc. Achieve good operational stability, high selectivity, and improved permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

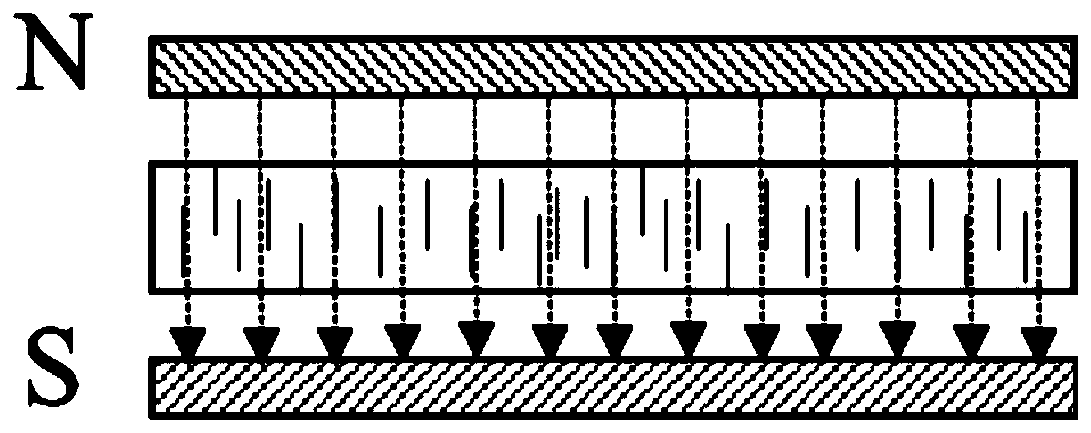

[0024] Embodiment 1, prepare the graphene oxide / sodium alginate composite membrane of vertically oriented loading ferric oxide, the steps are as follows:

[0025] Stir and ultrasonically disperse the 1mg / ml graphene oxide dispersion loaded with ferric oxide, wherein the graphene oxide has a lateral size of 500-1000nm and a thickness of 1-2nm. Take 380 μl of the dispersion liquid and add deionized water to disperse the filler, that is, graphene oxide loaded with ferric oxide, in 24.6 ml of deionized water.

[0026] Add 0.38 g of sodium alginate to the above dispersion, and stir at 30° C. for 5 hours to obtain a casting solution in which the mass ratio of graphene oxide loaded with ferric oxide to sodium alginate particles is 0.001:1.

[0027] Filter the above-mentioned casting solution, let it sit for defoaming, and then evenly spin-coat it on the polyacrylonitrile ultrafiltration membrane with a molecular weight cut-off of 1 million. 40s; a composite film was obtained.

[00...

Embodiment 2

[0030] Example 2, preparation of vertically oriented iron ferric oxide nanosheets / sodium alginate composite film to prepare a composite film, the steps are as follows:

[0031] Dissolve 0.6g of ferric chloride hexahydrate in 30ml of diethylene glycol, stir magnetically for 1h, add 1.5g of sodium acetate, stir magnetically for 0.5h to obtain a black solution, and conduct a solvothermal reaction at 200°C for 15h to obtain a black precipitate , the precipitate was successively washed with ethanol and water to obtain ferric oxide nanosheets with a size of 100-200nm and a thickness of 5-10nm. The product was stored in deionized water, and after stirring and ultrasonic dispersion, the quantitative After the dispersion was dried, the precipitate was weighed, and the concentration of the dispersion was 3 mg / ml. Stir and ultrasonically disperse the prepared iron ferric oxide dispersion evenly. Take 380 μl of the dispersion liquid and add deionized water to disperse the filler, namely ...

Embodiment 3

[0036] Embodiment 3, preparation of vertically oriented iron ferric oxide nanosheet / sodium alginate composite film, the steps are as follows:

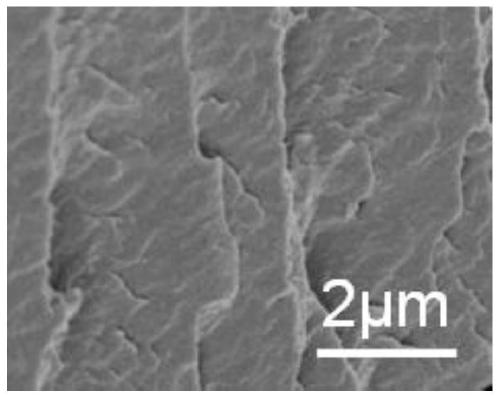

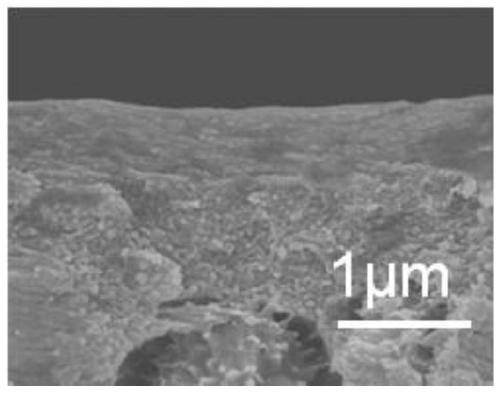

[0037] The preparation process is basically the same as in Example 2, except that in the film-forming process, the volume of the dispersion liquid is 507 μl, and the volume of deionized water is 24.5ml, so that the mass ratio of ferric oxide nanosheets to sodium alginate particles is 0.004:1 casting solution; after spin coating, it is dried between permanent magnets whose magnetic induction intensity is 200mT, and finally obtains a vertically oriented iron ferric oxide nanosheet / sodium alginate composite film, which is denoted as film 3, and the film 3 Cross section as image 3 shown.

[0038] Membrane 3 is used for pervaporation ethanol dehydration, and the permeation flux is 1783g / m under the conditions of 76°C and raw material concentration of 90 / 10wt% (ethanol / water) 2 h, the separation factor is 2762.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com