Water temperature control method and system

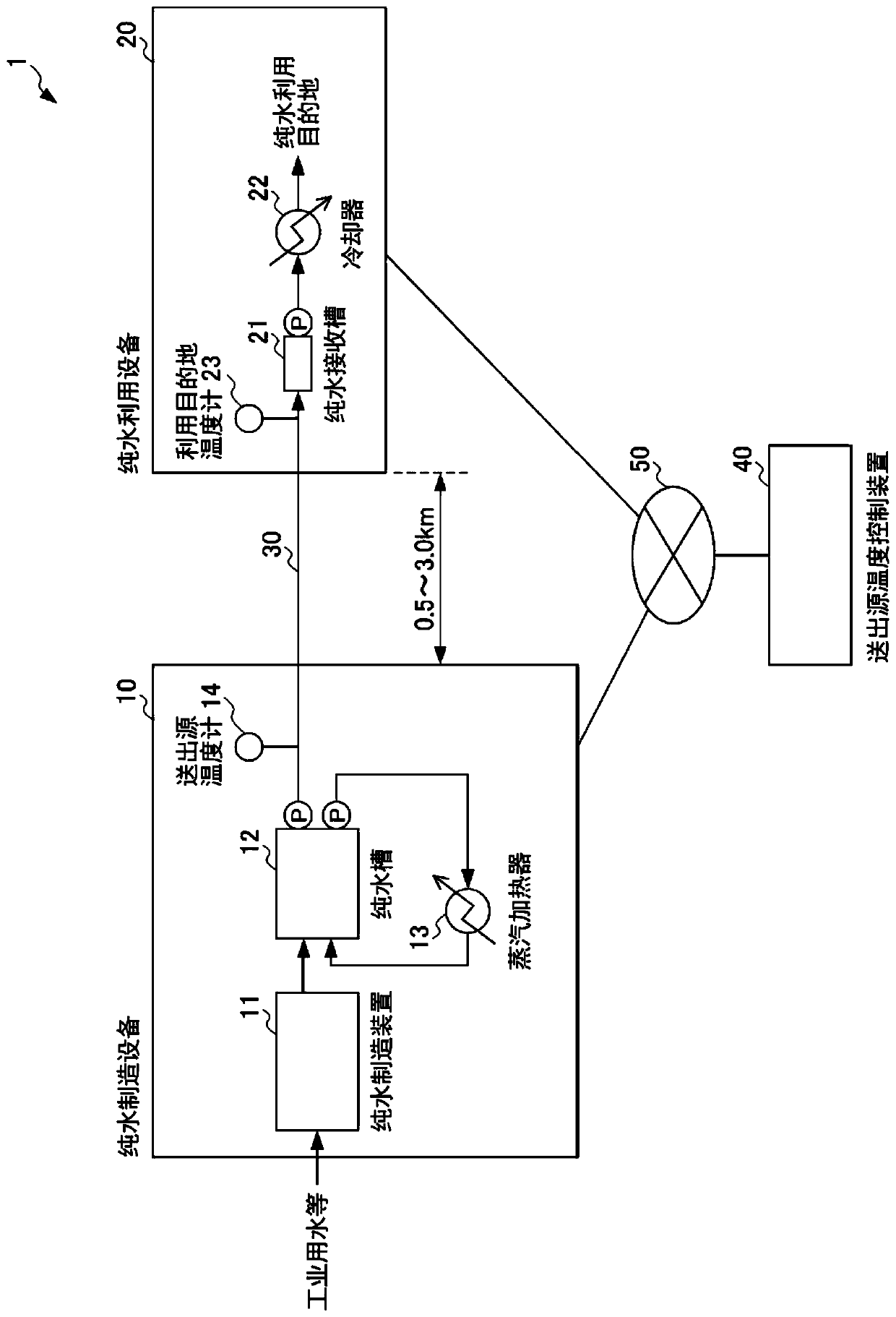

A water temperature control method and target temperature technology, applied in the direction of control/regulation system, temperature control, temperature control using electric means, etc., can solve problems such as difficulty, waste of energy, and lower heating temperature setting value of steam heater 113 , to save cost, supply heat and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0119] Hereinafter, the present invention will be specifically described through examples, but the present invention is not limited thereto.

[0120]

[0121] Using the water temperature control system 1 described in this embodiment, calculate the delivery source target temperature T of pure water in . Then, the steam heater 13 of the pure water manufacturing facility 10 is in to adjust the heat supply. Afterwards, if necessary, use the cooler 22 to reduce the utilization destination temperature T out Leave it fixed. Then, the pure water heating heat of the steam heater 13 at the delivery source (pure water manufacturing facility 10 ) and the pure water cooling heat of the cooler 22 at the utilization destination (pure water utilization facility 20 ) at this time are calculated.

[0122] The server 411 for data input acquires the outside air temperature T every minute through the communication network 50 0 , send source temperature T in , using the destination temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com