Low-cost high-power-density single-phase high-speed hybrid excitation permanent magnet motor and method

A high power density, permanent magnet motor technology, applied in synchronous motors with stationary armatures and rotating magnets, AC motor control, electric components, etc. and other problems to achieve the effect of improving performance and power density, reducing manufacturing costs, and avoiding magnetic performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

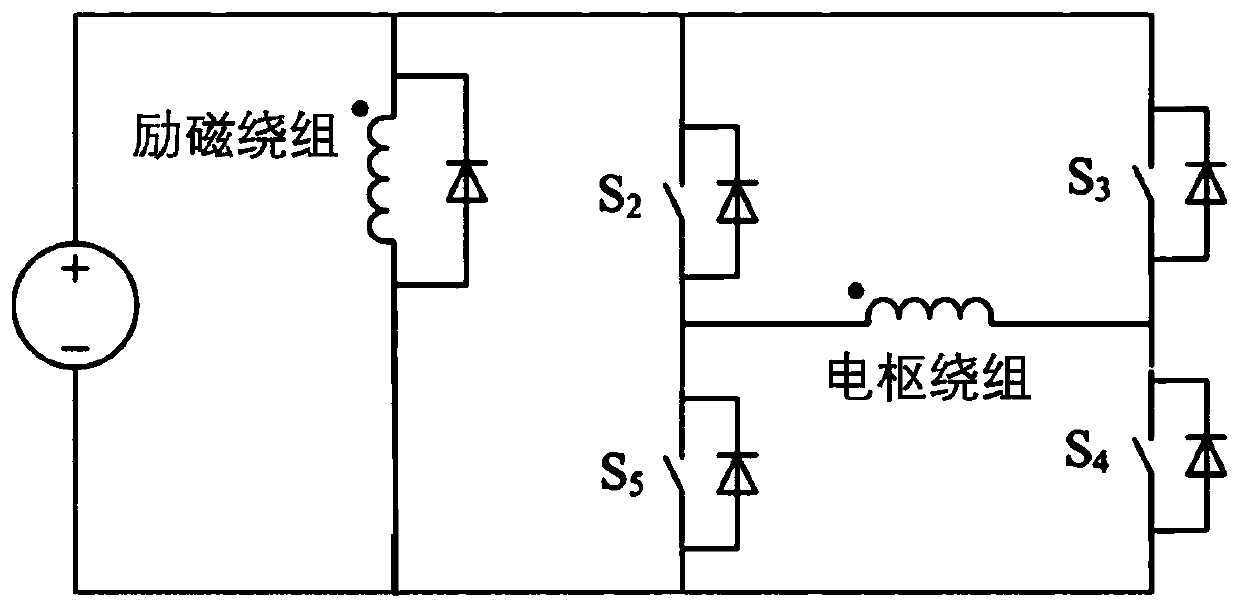

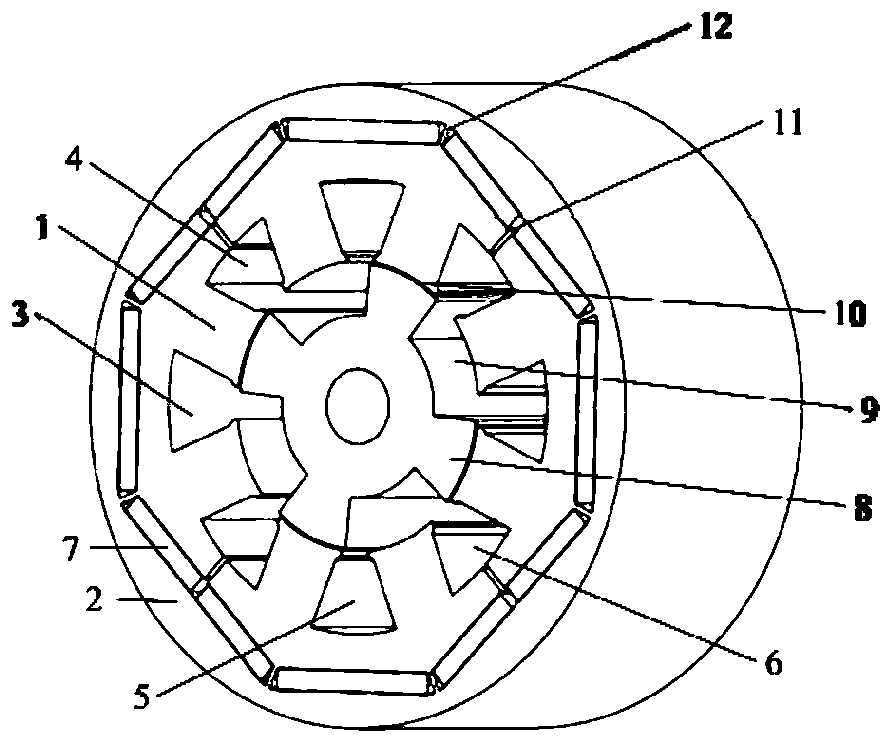

[0067] This embodiment discloses a low-cost, high-power-density single-phase high-speed hybrid excitation permanent magnet motor, including a stator and a rotor, and the stator includes stator slots, stator teeth, permanent magnet slots, and a stator yoke. The stator slot is composed of an armature slot and an excitation slot. A permanent magnet slot is arranged above the stator slot. A total of three pieces of ferrite with the same magnetization direction are placed between the additional air gaps. The permanent magnets are placed in the in the permanent magnet slot. The armature slots and excitation slots are alternately arranged at intervals along the circumference, a set of armature windings is placed in the armature slots, and a set of excitation windings is placed in the excitation slots. The magnetic concentration effect is realized by arranging the low-cost ferrite according to a certain angle, and the stator is connected into a whole through a magnetic bridge; the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com