Fuzzy controller secondary development design method based on Siemens_PLC platform

A fuzzy controller, secondary development technology, applied in the direction of program control, program control, electrical program control, etc. The effect of reducing personnel and facilitating communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the examples.

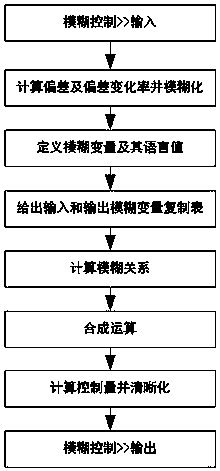

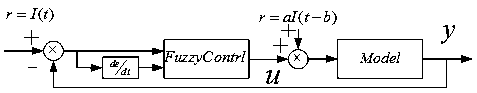

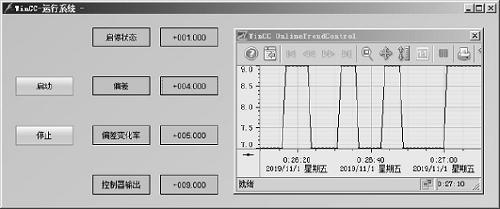

[0047] The invention discloses a fuzzy controller secondary development and design method based on the SIEMENS_PLC platform, based on the SIEMENS control system Step7_300_PLC platform and WinCC for secondary development, to construct a fuzzy controller, and the constructed fuzzy controller has a deviation and the rate of deviation change as input, control As output, where Step7_300_PLC is responsible for calculating the deviation of the written process value and the rate of deviation change , WinCC is responsible for writing the fuzzy control part; the specific construction of the fuzzy controller includes the following steps:

[0048] S1, fuzzy control input;

[0049] S2, calculate the deviation and the rate of deviation change and blur;

[0050] S3, defining fuzzy variables and their linguistic values;

[0051] S4, provide the input and output fuzzy varia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com