Granular foam stabilizer and its preparation method and application

A foam stabilizer and particle technology, which is used in the treatment of dyed polymer organic compounds, coatings, polyurea/polyurethane coatings, etc., to reduce production costs, improve foam stability, and achieve good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

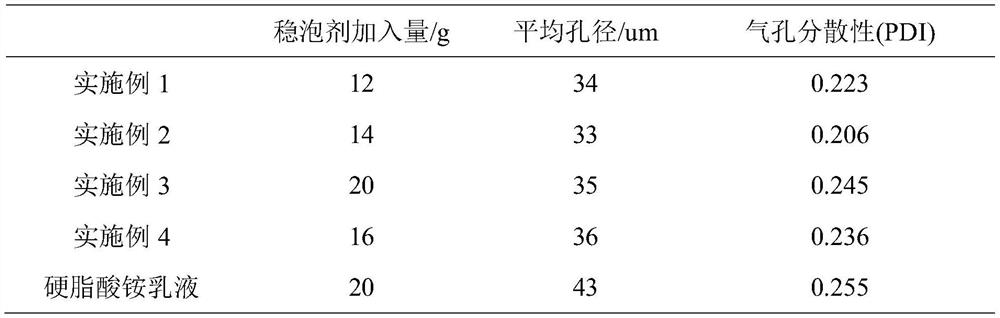

Examples

Embodiment 1

[0022] In terms of mass fraction, the raw materials of the granular foam stabilizer include: 30 parts of calcium carbonate (5 microns in particle size), 1.5 parts of sodium lauryl sulfate, and 200 parts of 10% ethanol-water solution.

[0023] The preparation steps of the particle foam stabilizer are as follows:

[0024] 1) Weigh 30 parts of calcium carbonate particles in a reaction kettle, add 200 parts of 10% ethanol-water solution, control the temperature to 40°C, and stir evenly to form a suspension;

[0025] 2) Add 1.5 parts of sodium lauryl sulfate to the calcium carbonate suspension, and continue to stir for 2 hours at 40°C;

[0026] 3) Stirring was stopped, the product was separated by suction filtration, and dried at 40° C. to obtain a calcium carbonate particle foam stabilizer.

Embodiment 2

[0028] In terms of mass fraction, the raw materials of the granular foam stabilizer include: 30 parts of calcium carbonate (with a particle diameter of 1 micron), 3 parts of sodium dodecylbenzenesulfonate, and 200 parts of 20% ethanol-water solution.

[0029] The preparation steps of this granular foam stabilizer are as follows:

[0030] 1) Weigh 30 parts of calcium carbonate particles in a reaction kettle, add 200 parts of 20% ethanol-water solution, control the temperature to 20°C, and stir evenly to form a suspension;

[0031] 2) Add 3 parts of sodium dodecylbenzenesulfonate to the calcium carbonate suspension, and continue stirring for 3 hours at 20° C.;

[0032] 3) Stirring was stopped, the product was separated by suction filtration, and dried at 60° C. to obtain a calcium carbonate particle foam stabilizer.

Embodiment 3

[0034] In terms of mass fraction, the raw materials of the granular foam stabilizer include: 30 parts of titanium dioxide (particle diameter: 0.1 micron), 1.5 parts of cetyltrimethylammonium bromide, and 200 parts of 40% ethanol-water solution.

[0035] The preparation steps of this granular foam stabilizer are as follows:

[0036] 1) Weigh 30 parts of titanium dioxide into a reaction kettle, add 200 parts of 40% ethanol-water solution, control the temperature at 60°C, and stir evenly to form a suspension;

[0037] 2) Add 1.5 parts of cetyltrimethylammonium bromide to the titanium dioxide suspension, and continue stirring at 60°C for 4 hours;

[0038] 3) Stirring was stopped, the product was separated by suction filtration, and dried at 60° C. to obtain a foam stabilizer of titanium dioxide particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com