Garbage penetrating fluid treatment method

A technology of waste permeate and treatment method, applied in the field of waste permeate treatment, can solve the problems of high organic content in discharged water, narrow recovery of heavy metals, clogging of filter layers, etc., and achieves reduction of organic content, reduction of influencing factors, and reduction of SS value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

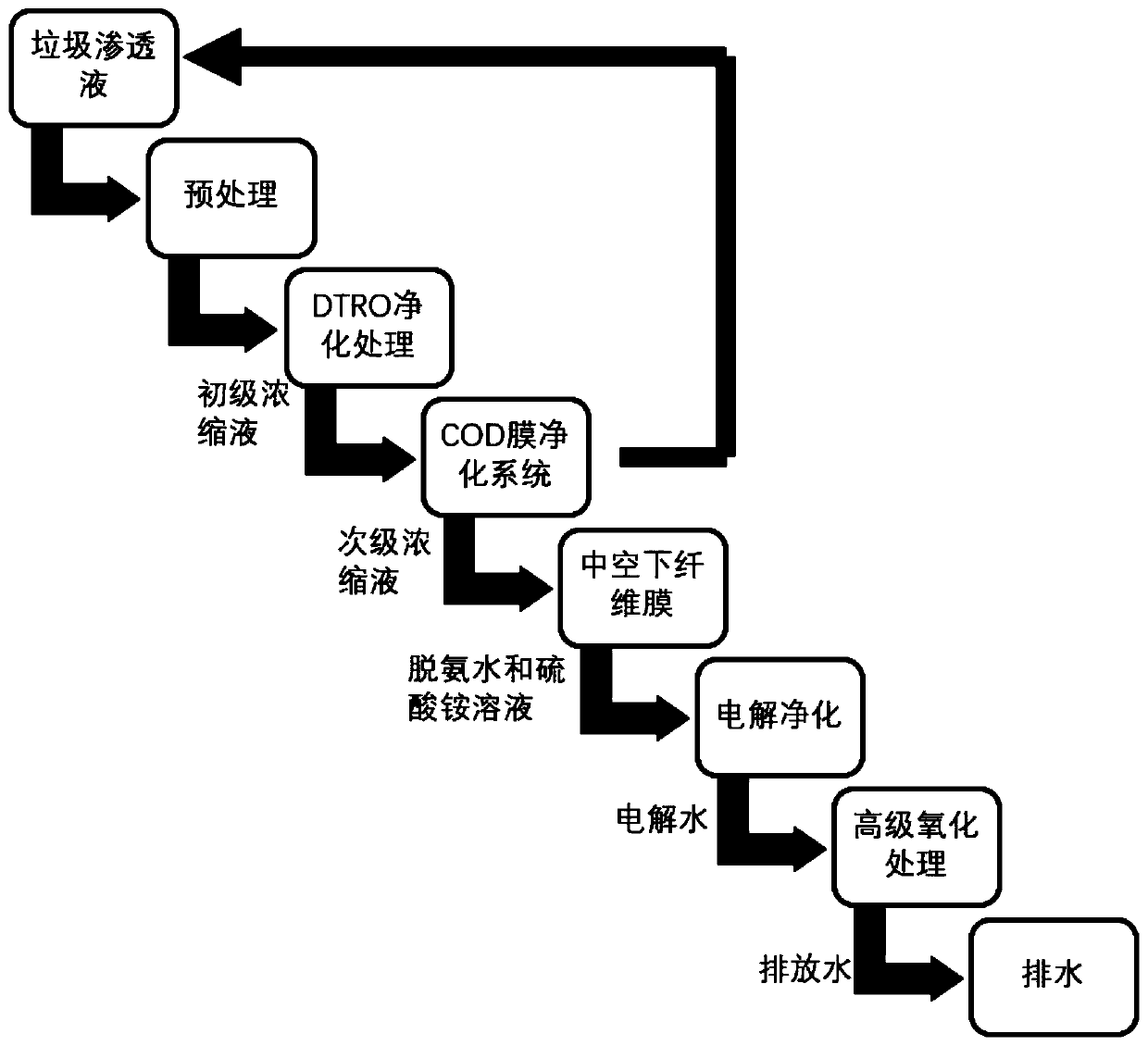

[0026] Such as figure 1 Shown, a kind of processing method of rubbish seepage fluid, comprises the following steps:

[0027] S1 After pretreatment, the garbage permeate enters the DTRO membrane to obtain the primary concentrated solution; the pretreatment is that the garbage permeate is firstly added with acid to adjust the pH, and then washed through the quartz sand filter, and then according to the process , The pressure difference at the water outlet is to determine whether backwashing is necessary. After the backwashing is completed, the washed sand filter water is washed with raw water to remove sand, and finally air-washed to remove impurities through compressed air; the backwashing judgment is specifically as follows: When the pressure difference between the inlet and outlet of the quartz sand filter exceeds 2.5bar, or when the SS value of suspended solids in the water is low and the pressure difference does not exceed 2.5bar after backwashing for 100h, the quartz sand ...

Embodiment 2

[0033] The added amount of the scale inhibitor is changed to be added at a mass ratio of silicon element and sulfate in the salt: scale inhibitor = 5:1, and the rest of the steps and formula are the same as in Example 1.

Embodiment 3

[0035] The added amount of the scale inhibitor is changed to be added at a mass ratio of silicon element and sulfate in the salt: scale inhibitor = 15:1, and the rest of the steps and formula are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com