Method for improving tenderness of mutton

A mutton tenderness technology, applied in the field of improving mutton tenderness, can solve the problem of very complicated tenderness control, achieve the effect of improving tenderness and taste, and retaining nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

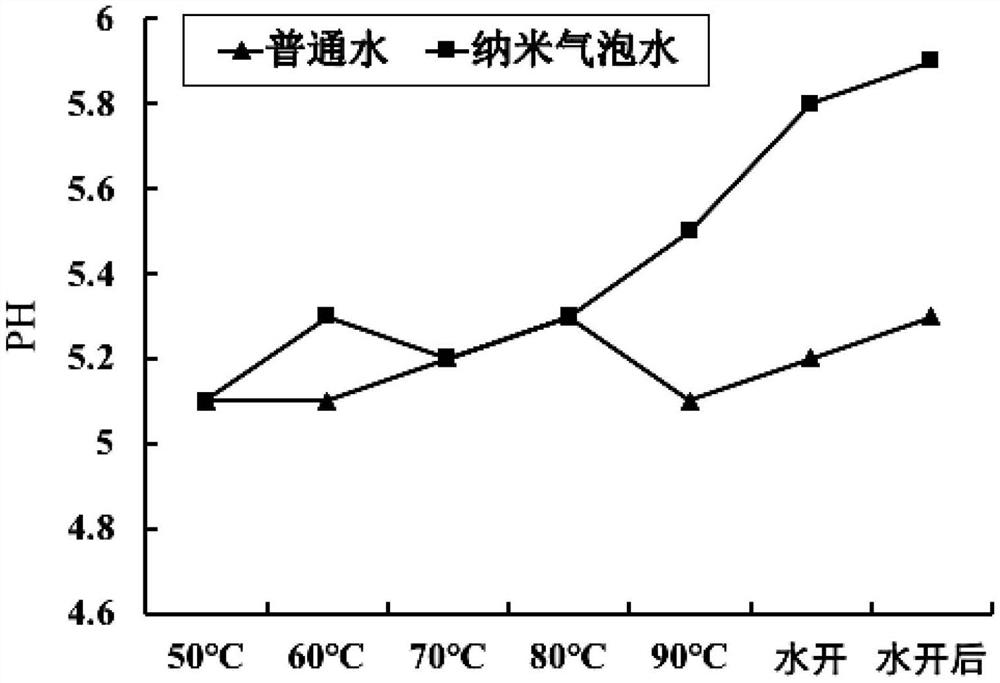

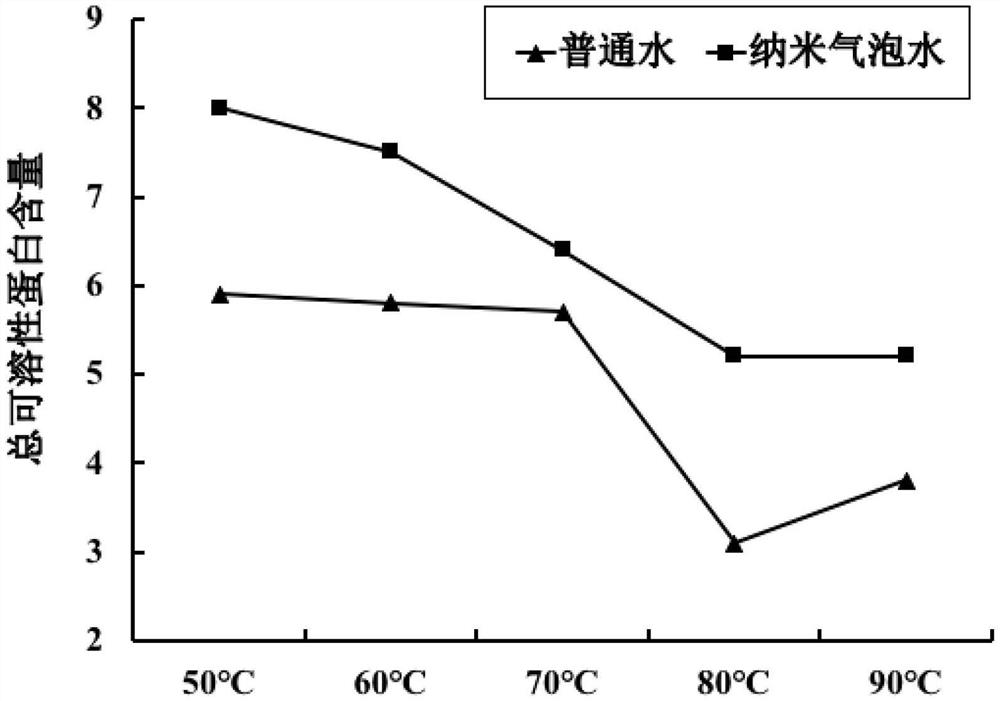

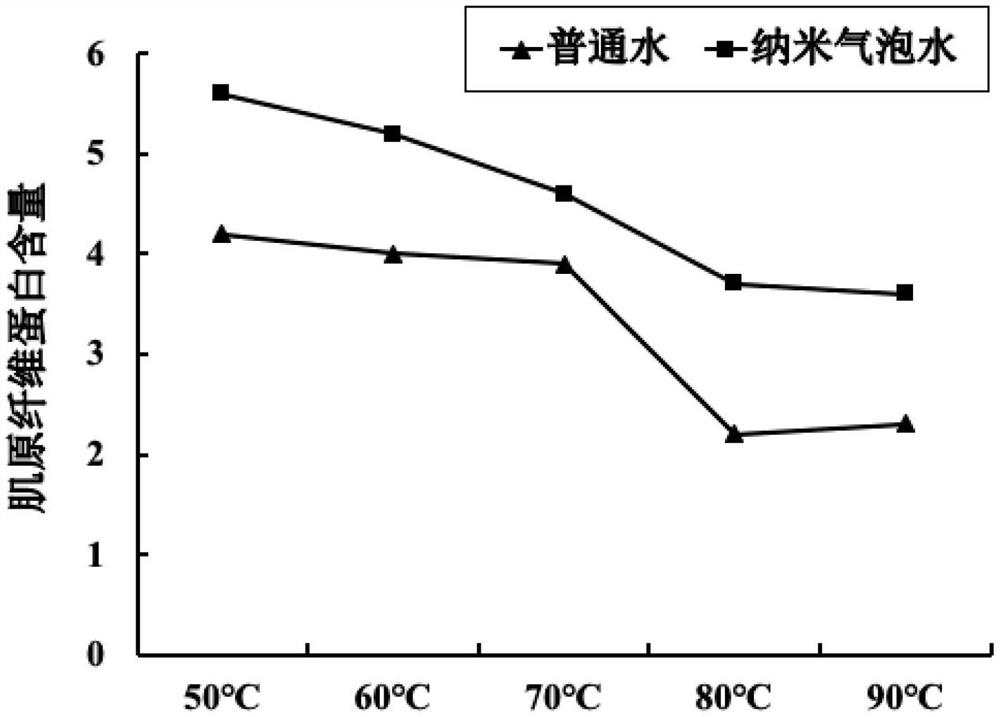

[0022] A kind of method of improving mutton tenderness of the present application comprises the following steps:

[0023] Step S1: Use the micro-nano bubble generation device (ie NANO MF-5000 micro-nano bubble generation system) to continuously prepare micro-nano bubbles in the water used for cooking mutton to prepare micro-nano bubble water, specifically, NANO MF-5000 micro-nano bubbles The generating system includes a gas-liquid mixing pump (produced by NANO Scientific) and a pressurizing device (produced by NANO Scientific). First, use the gas-liquid mixing pump to fully mix water and gas for 10-15 minutes, then use a pressurizing device to rotate at a high speed, and introduce the gas-liquid mixed fluid into the elliptical container in the device. The middle part forms a negative pressure axis, and the suction force of the elliptical container on the negative pressure axis can concentrate the gas mixed in the gas-liquid mixed fluid or the gas connected from the outside to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com