Movable rapid self-heating hydrogen production device and application thereof

A mobile device and hydrogen technology, applied in hydrogen, hydrogen production, inorganic chemistry, etc., can solve the problems of high hydrogen storage density, difficult liquefaction, and poor overall safety, and achieve high hydrogen concentration, fast response, and good Effect of Low Temperature Ammonia Decomposition Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

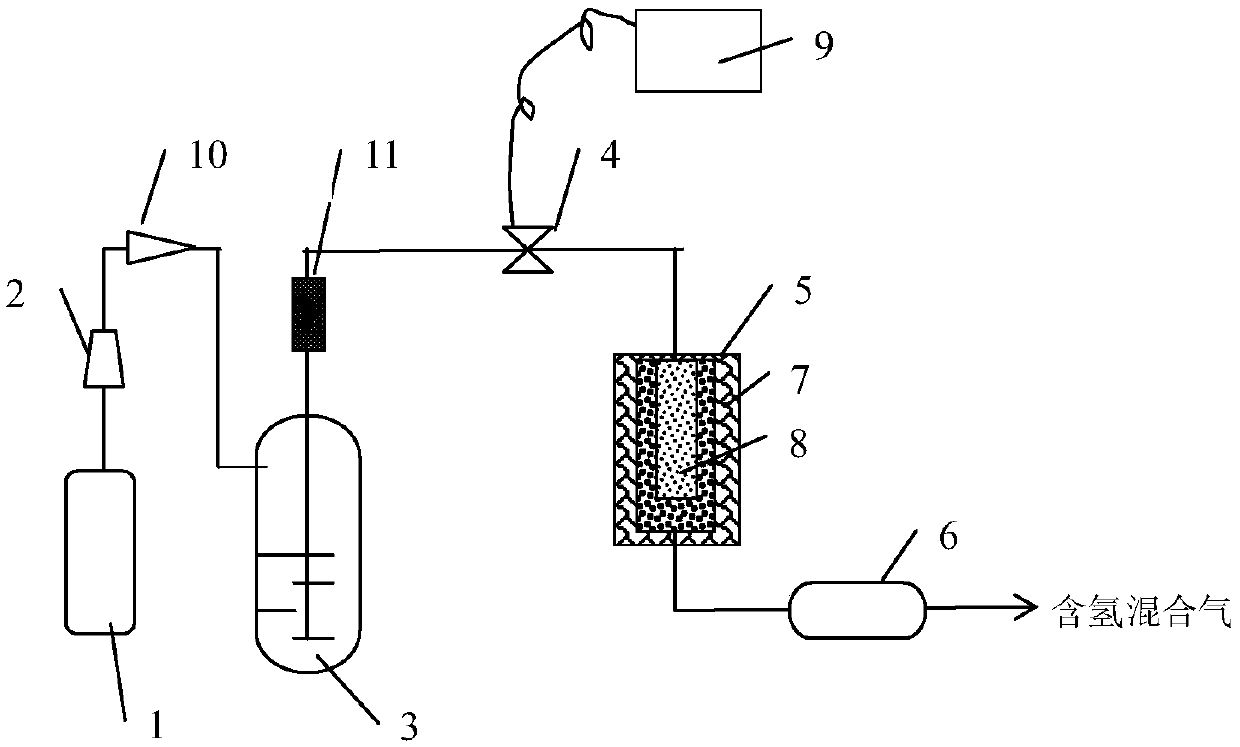

[0024] The invention uses hydrazine or hydrazine hydrate as a fuel, and provides a mobile on-site hydrogen production device that rapidly and autothermally decomposes the fuel to generate hydrogen. It includes a pressure cylinder 1, a pressure regulating valve 2, a hydrazine fuel storage tank 3, a catalytic reactor 5, and a purifier 6; the hydrazine fuel storage tank 3 and the catalytic reactor 5 are connected to each other through pipelines, and the outlet gas of the catalytic reactor 5 passes The purifier 6 is output from the external pipeline; the hydrazine fuel storage tank 3 is connected to the pressure gas cylinder 1 through a pipeline, and a pressure regulating valve 2 is provided on the connecting pipeline; the catalytic reactor 5 is covered with a quartz wool insulation layer 7, The catalytic reactor is filled with a high-efficiency catalyst bed 8;

[0025] On the connecting pipeline of hydrazine fuel storage tank 3 and catalytic reactor 5, be provided with filter 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com