Automatic beating device for scraper production

An automatic, rotating shaft technology, applied in the direction of impact tools, light impact tools, cleaning methods using gas flow, etc., can solve the problems of constantly moving scrapers, low work efficiency, and safety risks, so as to improve work efficiency and equipment Ease of use and clean equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

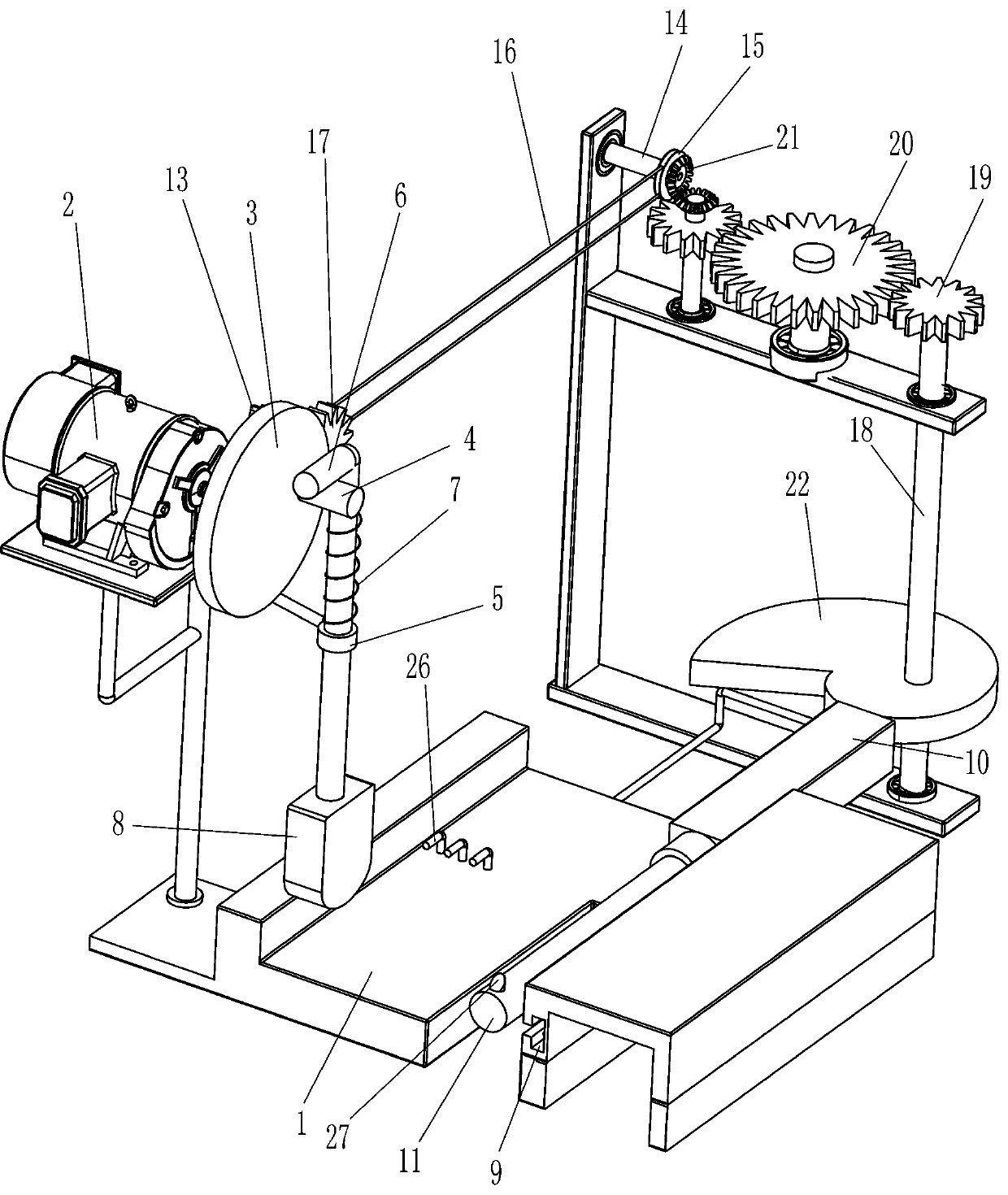

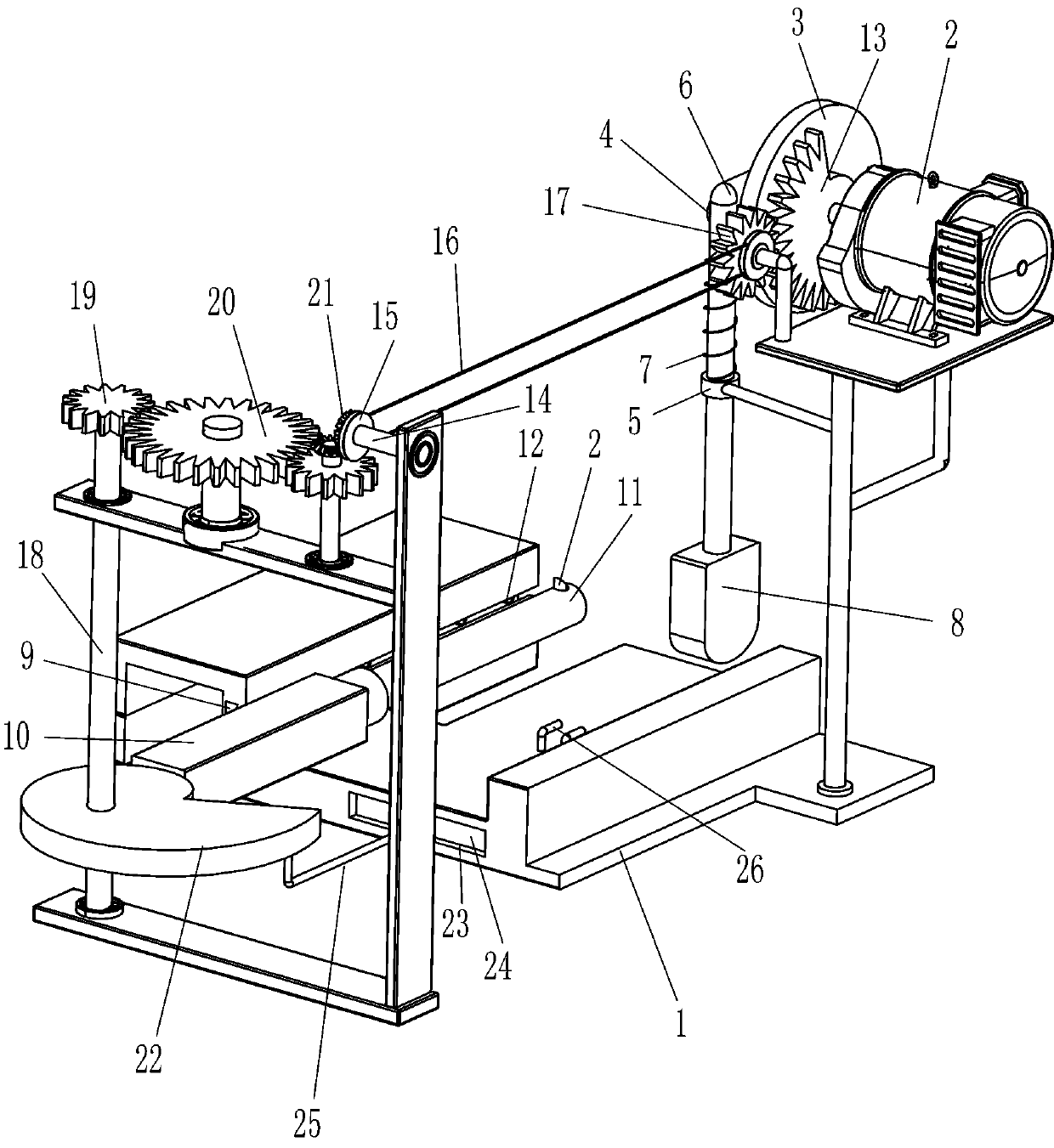

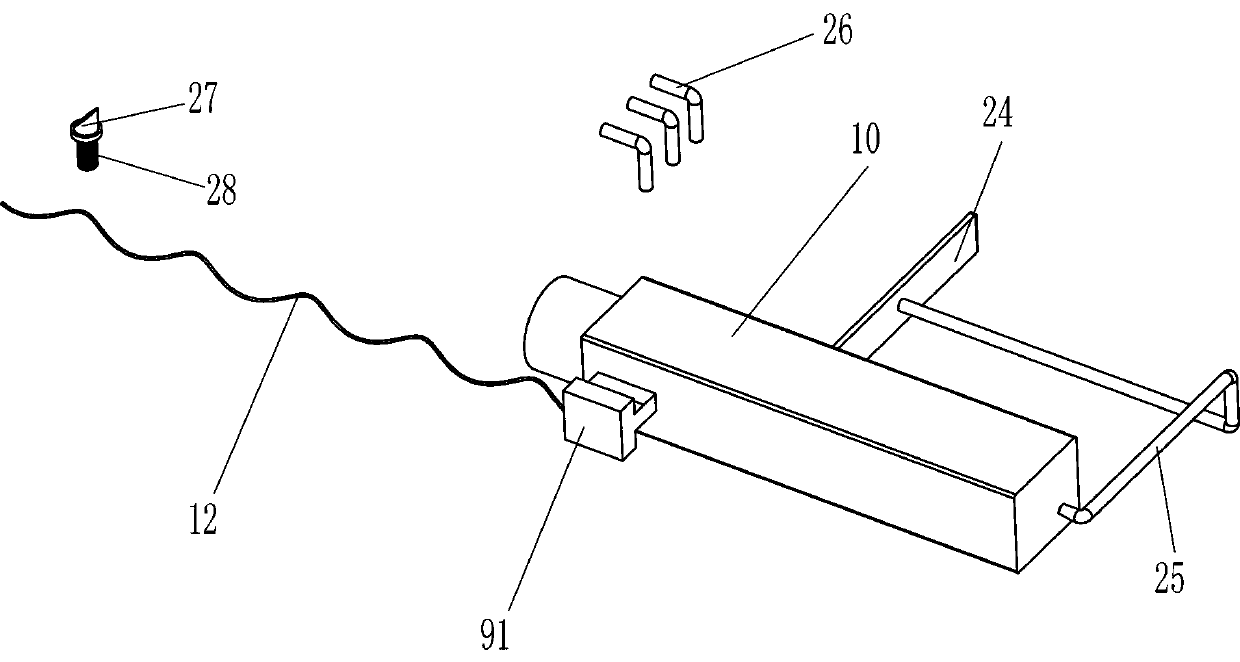

[0019] An automatic beating device for scraper production, such as figure 1 and 2 As shown, it includes a base 1, a hammer assembly and a placement assembly. The base 1 is provided with a hammer assembly powered by a motor, and the base 1 is provided with a placement assembly for placing a scraper.

[0020] Such as figure 1 and 2 As shown, the hammering assembly includes a geared motor 2, a disc 3, a push rod 4, a guide sleeve 5, an L-shaped sliding rod 6, a first spring 7 and a knocking block 8, and a geared motor is provided on the front left side of the top of the base 1 2. A disc 3 is provided on the output shaft of the gear motor 2, a push rod 4 is provided at the eccentric position on the right side of the disc 3, a guide sleeve 5 is provided on the left front side of the base 1, and an L-shaped sliding type is provided inside the guide sleeve 5. Slide bar 6, the first spring 7 is connected between the L-shaped slide bar 6 and the guide sleeve 5, the L-shaped slide ba...

Embodiment 2

[0026] Such as figure 1 and 2 As shown, on the basis of Embodiment 1, in order to use the device better, it also includes a sector gear 13, a first rotating shaft 14, a pulley 15, a flat belt 16, a first gear 17, a second rotating shaft 18, The second gear 19, the third gear 20, the bevel gear 21 and the cam 22, the disc 3 is provided with a sector gear 13, the left part of the rear side of the base 1 is provided with the first rotating shaft 14 through the rotation of the bearing seat, and the front side of the base 1 The left rotary type is provided with a first gear 17, the first gear 17 meshes with the sector gear 13, the first rotating shaft 14 and the first gear 17 are all keyed with a pulley 15, and a flat belt 16 is wound between the pulleys 15, and the base 1. The rear right part of the rotating type is provided with a second rotating shaft 18. Both the top of the second rotating shaft 18 and the rear left part of the base 1 are provided with a second gear 19. The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com