Embedded resistor structure and manufacturing method thereof

A manufacturing method and technology of embedding resistors, which are applied in directions including printed resistors, printed circuit manufacturing, and removal of conductive materials by chemical/electrolytic methods. It can solve the problems of multiple resistor manufacturing processes and difficult control of resistor wires, and achieve line protection. The effect of no change and less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means and effects that the present invention takes to reach the intended purpose of the invention, the following in conjunction with the appended Figure 1-9 And the preferred implementation mode, the specific implementation mode, structure, characteristics, method and effect of the embedded resistor and its manufacturing method provided by the present invention are described in detail as follows.

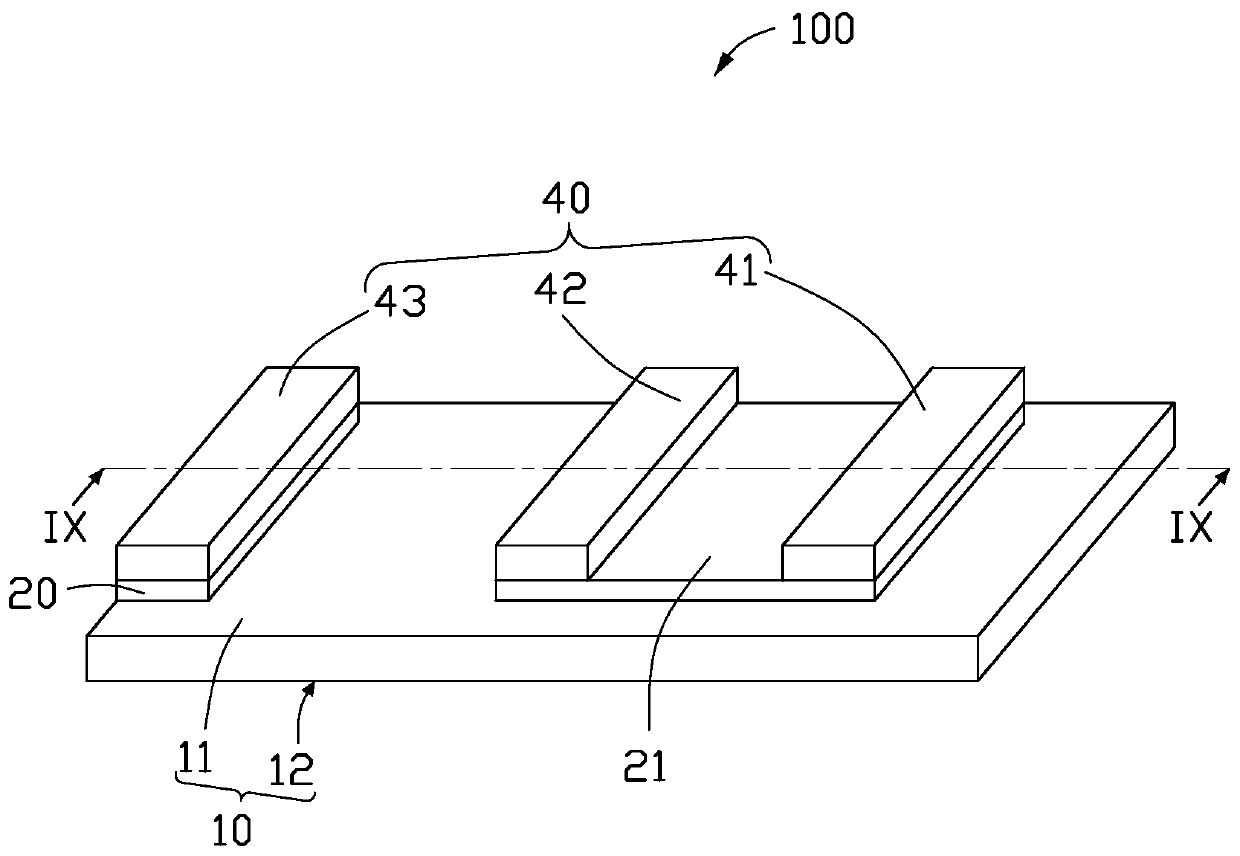

[0031] see figure 1 , the present invention provides a buried resistor structure 100 .

[0032] Wherein, the embedded resistor structure 100 may be a single-sided embedded resistor, or may be a double-sided embedded resistor. In this embodiment, the embedded resistor structure 100 is a single-sided embedded resistor.

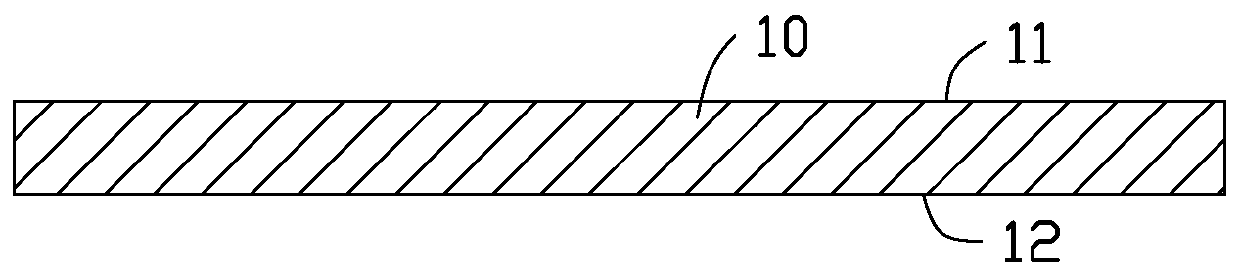

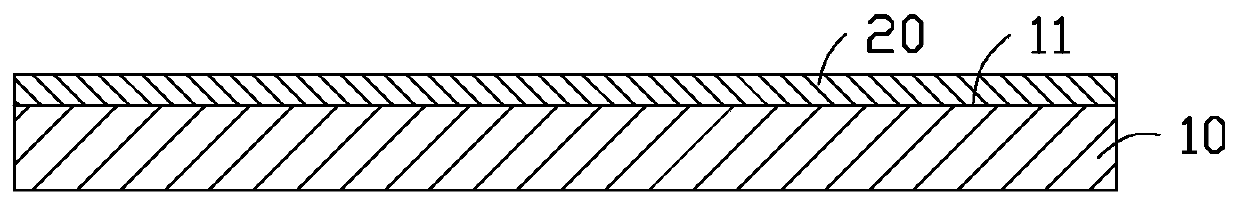

[0033] Specifically, the embedded resistance structure 100 includes a substrate layer 10 , a resistance material layer 20 and a copper plating layer 40 . Wherein, the resistive material layer 20 is formed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com