A Buck DC-DC Converter Topology

A technology of DC converter and topology structure, which is applied in the direction of DC power input conversion to DC power output, high-efficiency power electronic conversion, output power conversion device, etc., and can solve the problem of low energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below in conjunction with the accompanying drawings.

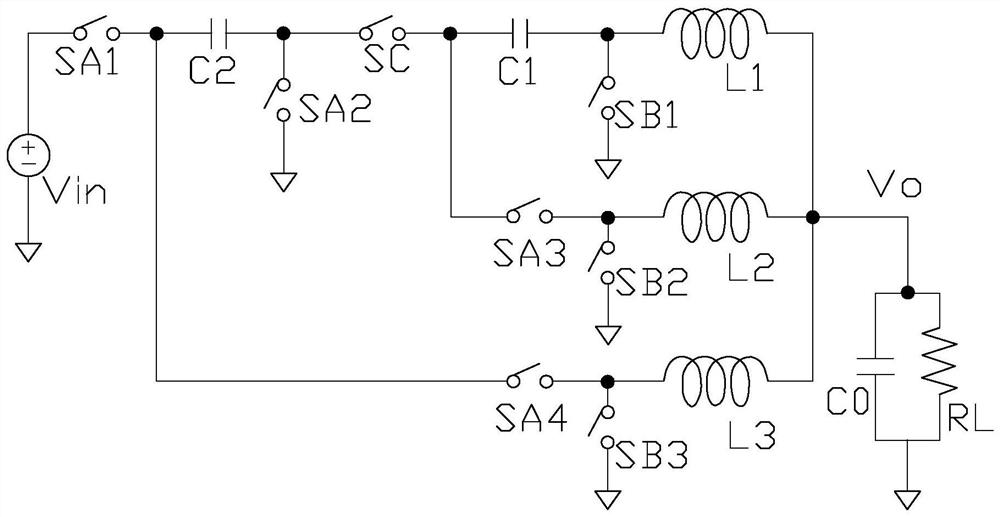

[0058] refer to image 3 , is a step-down DC-DC converter topology disclosed in the present invention, including: a freewheeling element, an energy storage element, a control element, and a load element. The load element includes a filter capacitor C0 and a load RL connected in parallel. The freewheeling element is electrically connected to the load element for providing a stable current output to the load element, including a first inductance L1, a second inductance L2 and a third inductance L3, and one end of the three is connected to the load element, the first inductance L1 , The second inductance L2 and the third inductance L3 can adopt air-core coils, ferrite coils, iron-core coils, and copper-core coils. The first inductor L1, the second inductor L2, the third inductor L3 and the filter capacitor C0 form an LC output filter network.

[0059] The ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com