Preparation and application of manganese dioxide@sulfur@carbon sphere positive electrode composite material with yolk-shell structure

A manganese dioxide and composite material technology, applied in structural parts, battery electrodes, electrical components, etc., can solve problems such as the inability to effectively inhibit the dissolution of lithium polysulfides, the difficulty in efficiently adsorbing lithium polysulfides, and the inability to effectively inhibit the shuttle effect, etc. Achieving the effect of being conducive to full contact, improving low electronic conductivity, and high specific energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The process of preparing manganese dioxide@carbon material with yolk-shell structure is the same as that of the comparative example. Take 0.1g of manganese dioxide@carbon material, grind it with 0.4g of sublimated sulfur, transfer it to a sealed reactor, heat treat at 155°C for 12h, 300 Heat treatment at ℃ for 2 hours to obtain a manganese dioxide@sulfur@carbon composite material with a yolk-shell structure. The carbon content in the composite material is 24.9%, the manganese dioxide content is 12.6%, and the sulfur content is 62.5%. Among them, the hollow carbon sphere The inner diameter of the cavity is 500nm, the thickness of the carbon layer is 30nm, and the specific surface area is 598m 2 g -1 , the pore volume is 0.584cm 3 g -1 , the coating of the subsequent pole piece and the assembly test of the battery are the same as the comparative example.

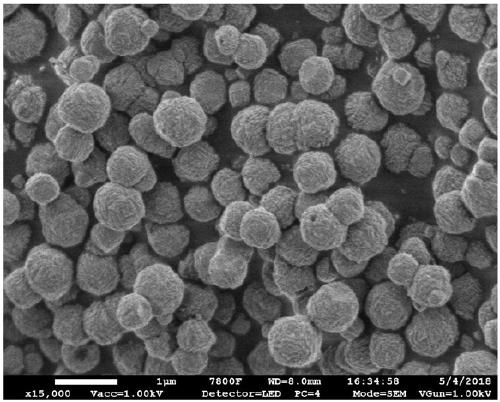

[0038] Depend on figure 1 It can be seen that the particle size of manganese carbonate is 600+100nm, from which i...

Embodiment 2

[0044] Manganese carbonate is prepared with comparative example;

[0045] Take 0.1g of manganese carbonate, add 0.1g of CTAB, 5ml of deionized water, 65ml of ethanol, 1ml of concentrated ammonia water, ultrasonically disperse for 30min, add 20ml of ethanol solution containing 0.4ml of tetraethyl orthosilicate within two hours, continue the reaction for 4h, pump Filtration, washing, and drying to obtain manganese carbonate@silicon dioxide with a core-shell structure;

[0046] The manganese dioxide@carbon material with yolk-shell structure is prepared in the same way as the comparative example, and the subsequent sulfur dipping, coating pole piece and battery assembly test are the same as in Example 1. The carbon content in the composite material is 23.5%, and the manganese dioxide content is 13.1% %, the content of sulfur is 63.4%. Among them, the inner diameter of the hollow carbon sphere is 400nm, the thickness of the carbon layer is 30nm, and the specific surface area is 548...

Embodiment 3

[0049] Manganese carbonate is prepared with comparative example;

[0050] Take 0.1g of manganese carbonate, add 0.1g of CTAB, 5ml of deionized water, 65ml of ethanol, 1ml of concentrated ammonia water, ultrasonically disperse for 30min, add 20ml of ethanol solution containing 1.2ml of tetraethyl orthosilicate within two hours, continue the reaction for 4h, pump Filtration, washing, and drying to obtain manganese carbonate@silicon dioxide with a core-shell structure;

[0051] Manganese dioxide@carbon material with yolk-shell structure is the same as the comparative example, and the subsequent sulfur immersion, coating pole pieces and battery assembly tests are the same as in Example 1. The carbon content in the composite material is 24.7%, and the manganese dioxide content is 13.4% %, the content of sulfur is 61.9%. Among them, the inner diameter of the hollow carbon sphere is 600nm, the thickness of the carbon layer is 25nm, and the specific surface area is 462m 2 g -1 , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com