Thin film circuit with large-area side wall metal pattern and preparation method thereof

A technology of metal graphics and thin film circuits, applied in circuits, electrical components, electric solid devices, etc., can solve problems such as complex operations and easy problems, and achieve the effect of ensuring positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0042] A method for preparing a thin film circuit with a large-area sidewall metal pattern, comprising the following steps:

[0043] (1) Use a laser to make a shape mark at the position of the cavity on the surface of the substrate. At this time, the depth of laser processing does not penetrate the thickness of the substrate, and the shape mark can be seen clearly;

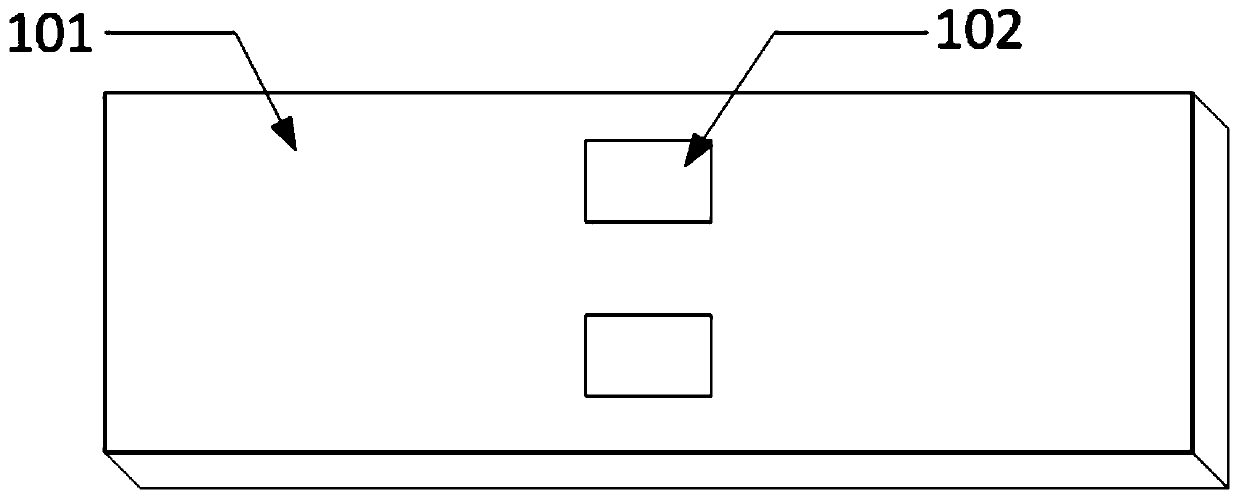

[0044] Such as figure 1 As shown, a substrate 101 with a thickness of 0.1 mm to 1 mm (the type can be alumina ceramics, aluminum nitride ceramics, quartz, silicon, etc.) is put into the laser processing equipment, and the cavity shape mark 102 is processed by laser. The depth of the shape mark is not more than 50µm, which is much smaller than the thickness of the substrate. The shape mark 102 at the position of the laser processing cavity can be a regular quadrilateral or an irre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com