Rolling rock breaking drill bit with working face state and hob operation state monitoring function

A technology for operating conditions and working faces, which is applied in earth-moving drilling, mining equipment, mining equipment, etc., and can solve problems such as fracture of the center pipe of the drill bit, low drilling efficiency, and gas explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

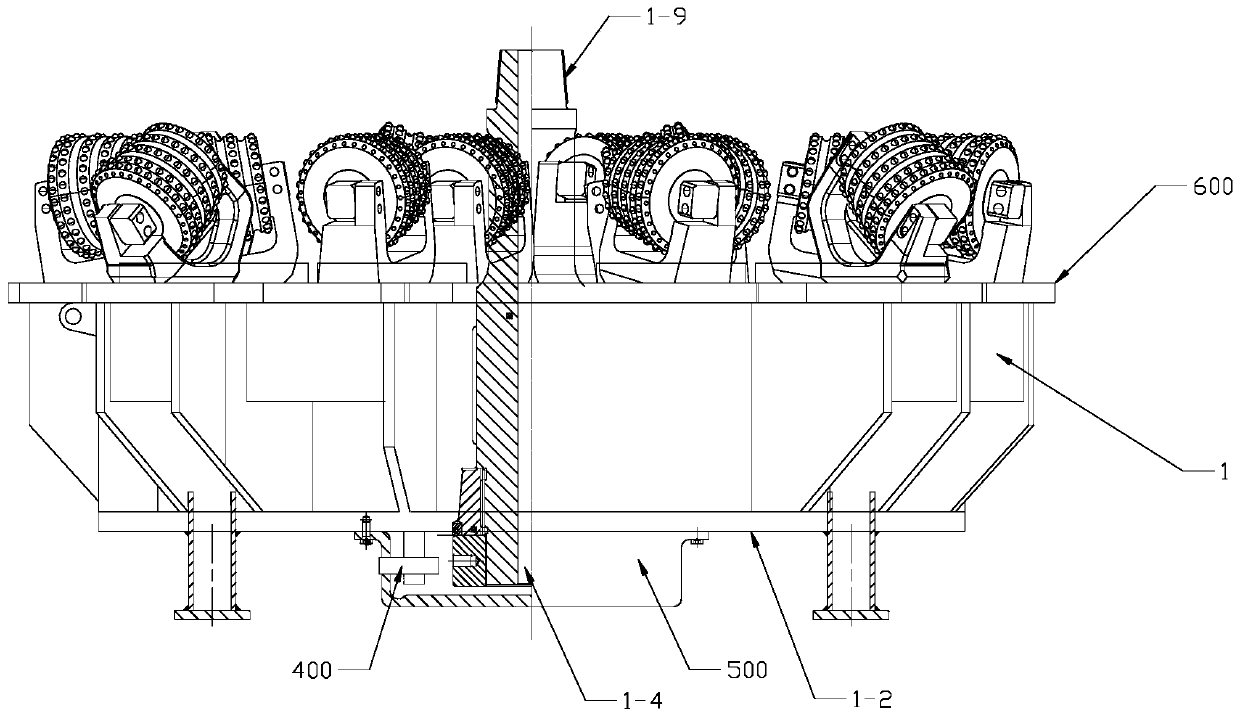

[0034] Such as figure 1 As shown, a rolling rock-breaking drill bit with working surface status and hob operating condition monitoring includes a rolling rock-breaking drill bit 600 and a temperature sensor 100 fixedly installed on the rolling rock-breaking drill bit 600, a rotating speed Sensor 200, gas sensor 300, laser rangefinder 400 and data acquisition system 500; the data output end of the temperature sensor 100, the data output end of the rotational speed sensor 200, the data output end of the gas sensor 300 and the The data output terminals of the laser rangefinder 400 are respectively connected to the data input terminals of the data acquisition system 500 .

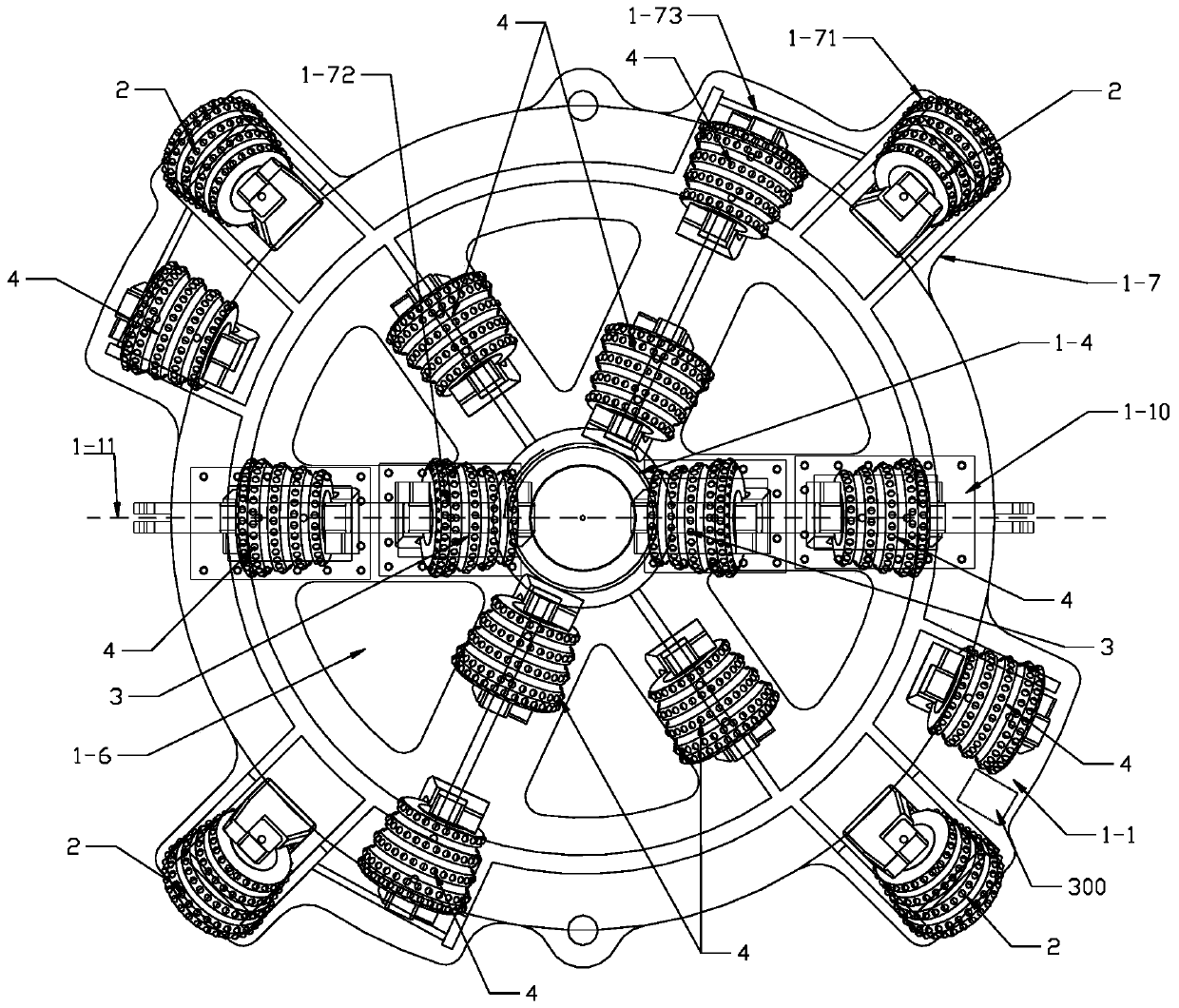

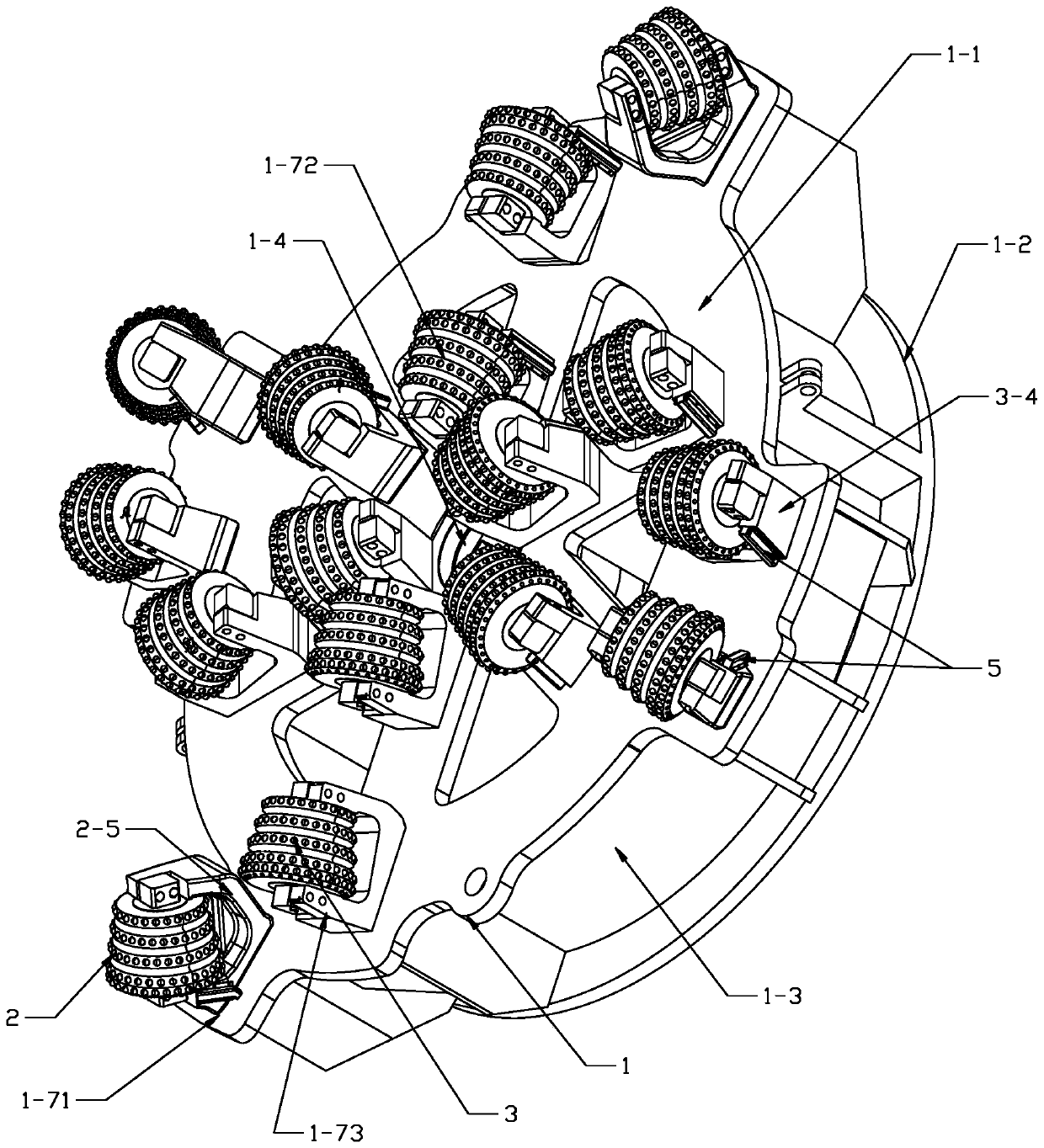

[0035] Such as figure 2 and image 3 As shown, the rolling rock breaking drill bit 600 includes a drill body 1, a side cutter body 2, a central cutter body 3 and a positive cutter body 4, and the side cutter body 2, the central cutter body 3 and the positive cutter body 4 They are fixedly installed on the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com