Cabled shuttle ore hauling submersible for deep sea mining and operation method thereof

A deep-sea mining and submersible technology, which is applied in underwater operation equipment, mineral mining, special mining, etc., can solve the problems of limited energy and difficult operation of shuttle ore transport submersibles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

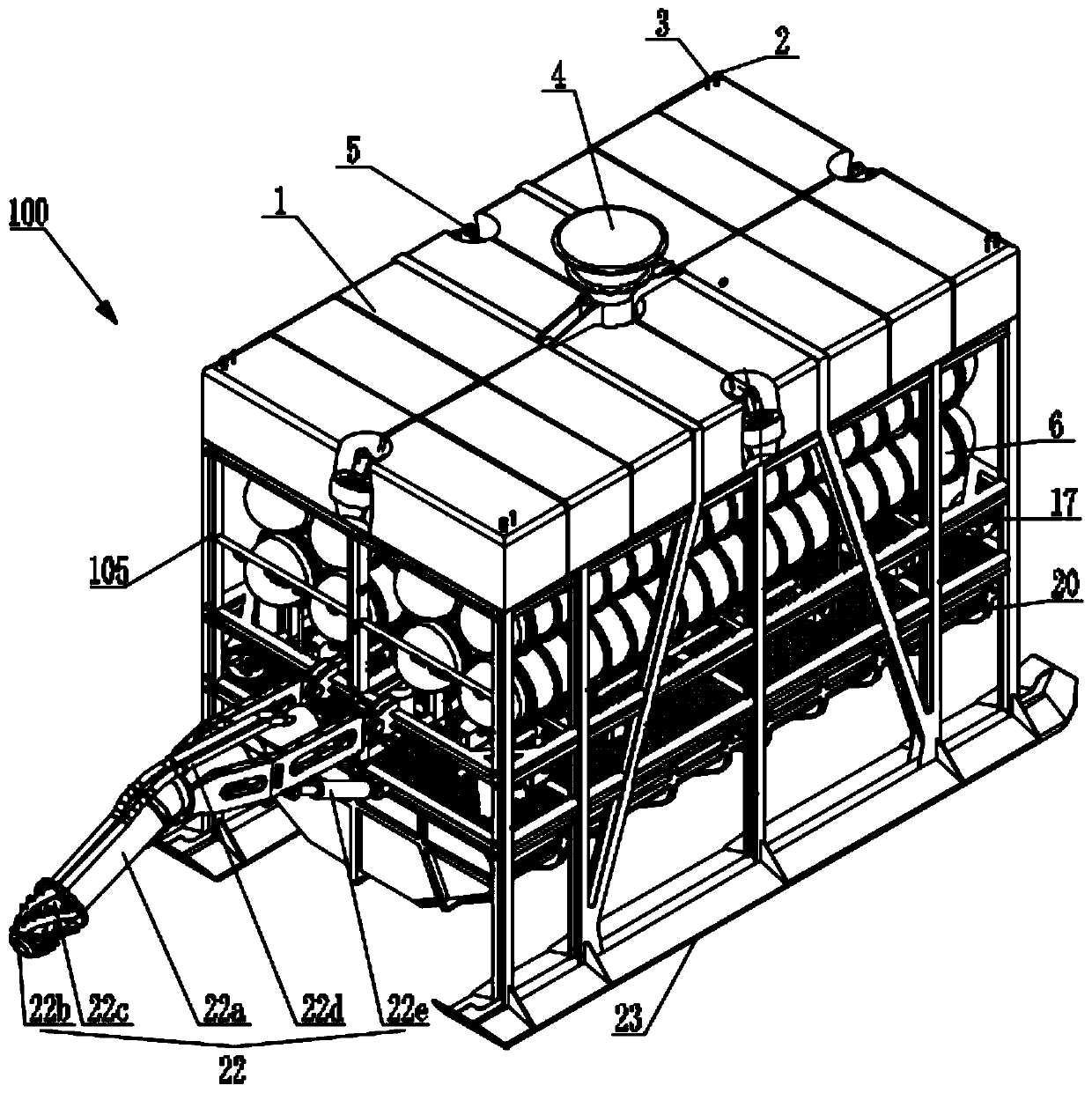

[0034] Such as figure 1 and figure 2 As shown, the structure of the cable shuttle ore transport submersible for deep-sea mining in this embodiment is as follows: the submersible 100 includes a carrier frame 105, and the carrier frame 105 is divided from top to bottom by support members: buoyancy material arrangement Area 101, adjustable ballast water tank arrangement area 102, equipment arrangement area 103, and cargo hold area 104, the bow front part of carrier frame 105 is equipped with ore slurry cutter suction mechanical arm 22; Skid plate 23 realizes submersible 100 seat bottoms and prevents sinking into seabed silt;

[0035] The slurry twisting mechanical arm 22 includes a mechanical arm body 22a, one end of which is rotatably connected to the carrier frame 105, and the other end is connected to the stirring head 22b, and a pump s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com