Gantray crane having circulating trolleys

A cyclic, crane technology, applied in the direction of trolley cranes, cranes, load hanging elements, etc., can solve the problems of delayed container transportation, difficult container positioning, and reduced loading and unloading speed and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

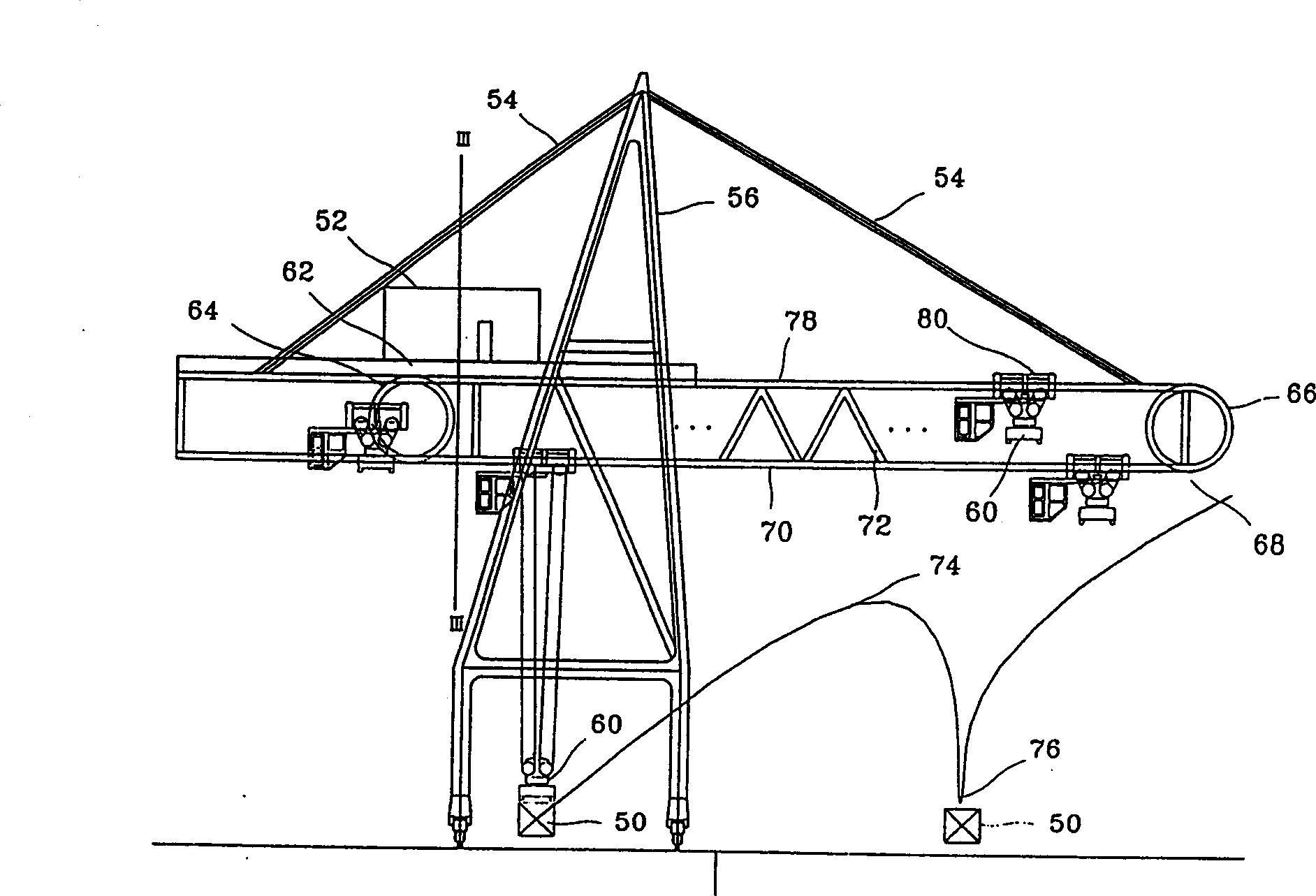

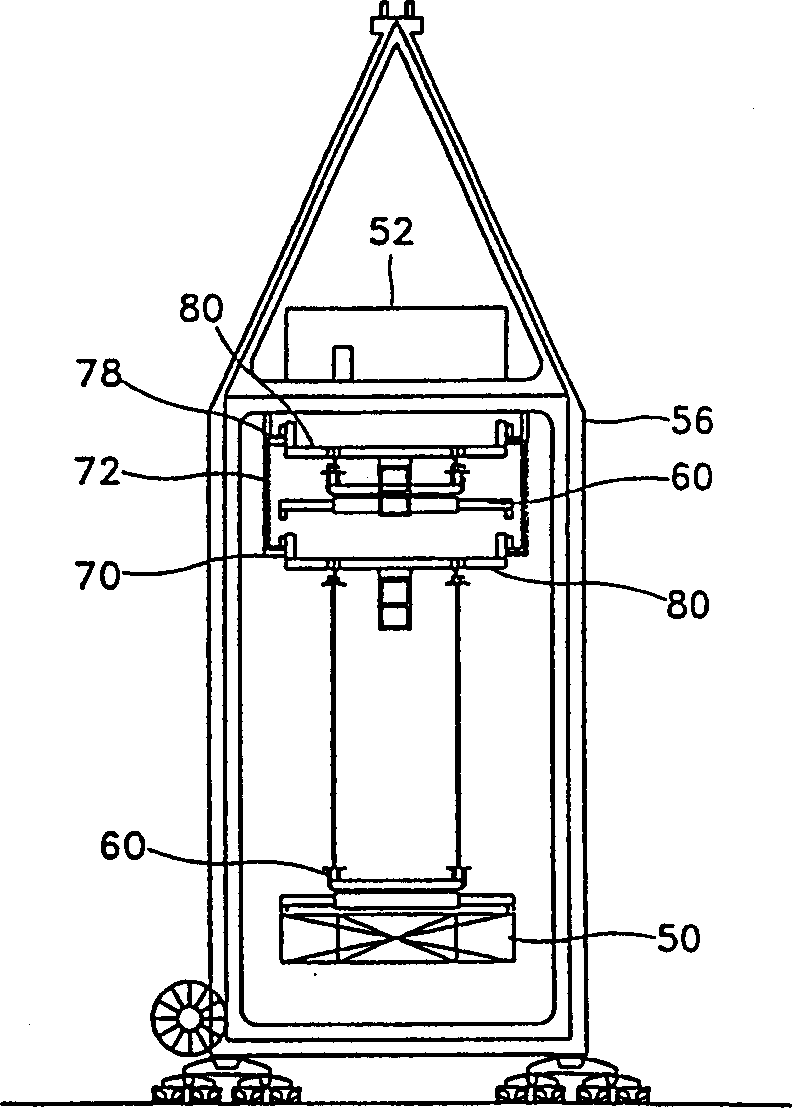

[0015] refer to figure 2 , shows the vertical circulation tower crane invented by the applicant, the first boom 70 is installed parallel to the ground at the predetermined height of the movable main tower column 56, and the second boom 78 is installed first A predetermined distance above the heavy arm 70 and parallel thereto. The tie bar 54 is connected to the second boom 78 to prevent the first and second booms 70 and 78 from sagging, and the first and second booms 70 and 78 are connected to each other by the connecting member 72, thereby forming a truss structure .

[0016] A plurality of cranes 80 having lashing beams 60 are movably mounted on the first and second booms 70 and 78 . The first and second circulating boom attachment devices 66 and 64 are mounted on the respective ends of the first and second booms 70 and 78 so that the crane 35 can move between the first and second booms 70 and 78. Cycle between runs. The machinery room 52 for controlling the first and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com