Dry-drilling drill bit and using method thereof

A drill bit, drilling and milling bit technology, applied in drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of unpopular use and high cost of air drilling, and achieve high construction efficiency and prevent environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

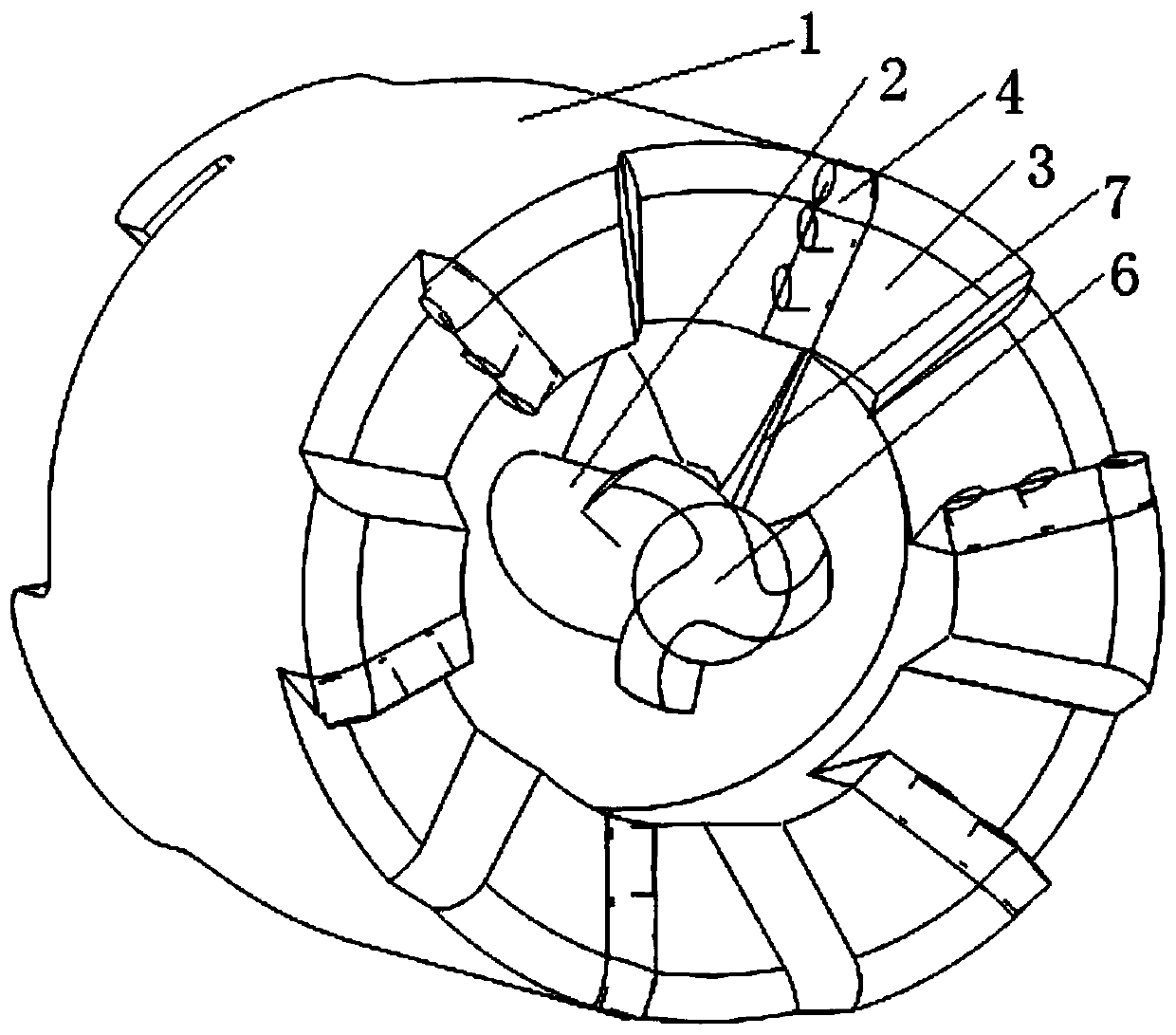

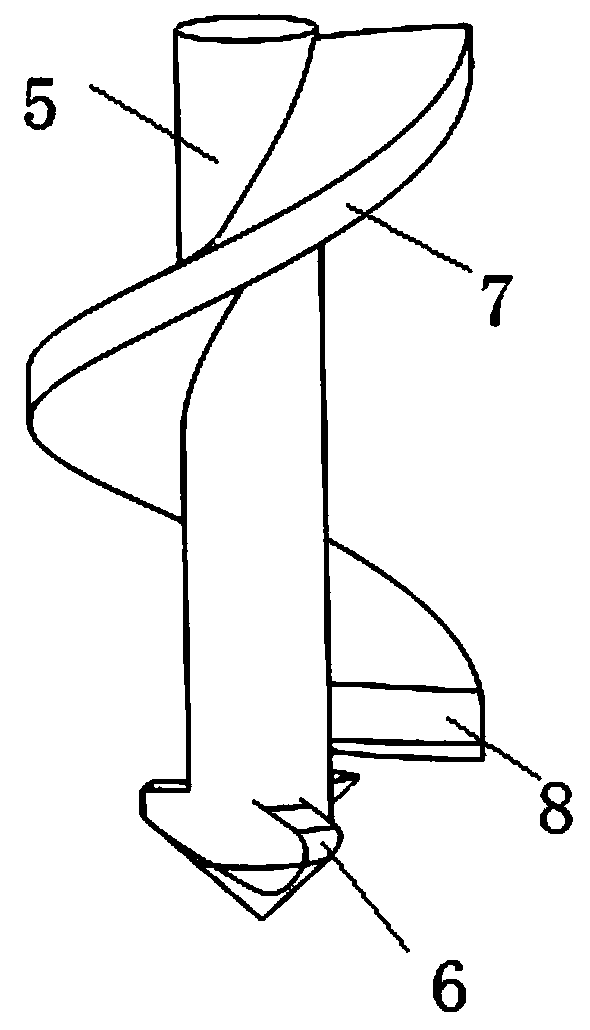

[0027] refer to figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, a dry drilling bit, including a dry drilling bit 1 and a drilling and milling bit 2 for breaking rock formations and transporting cuttings, the dry drilling bit 1 is a hollow cylindrical structure, and the drill Milling head 2 is fixedly connected to the central position in the hollow cylindrical structure of dry drilling bit 1, and the bottom of the drill bit end of drilling milling head 2 and the drill bit end of dry drilling bit 1.

[0028] In actual use: the dry drilling bit 1 is a hollow cylindrical structure, the drilling and milling head 2 is fixedly connected to the center of the hollow cylindrical structure of the dry drilling bit 1, and the bottom of the drill end of the drilling and milling head 2 is in contact with the dry drilling At the end of the drill bit 1, the dry drilling bit of the present invention can take out cuttings from the core of the drill bit with...

Embodiment 2

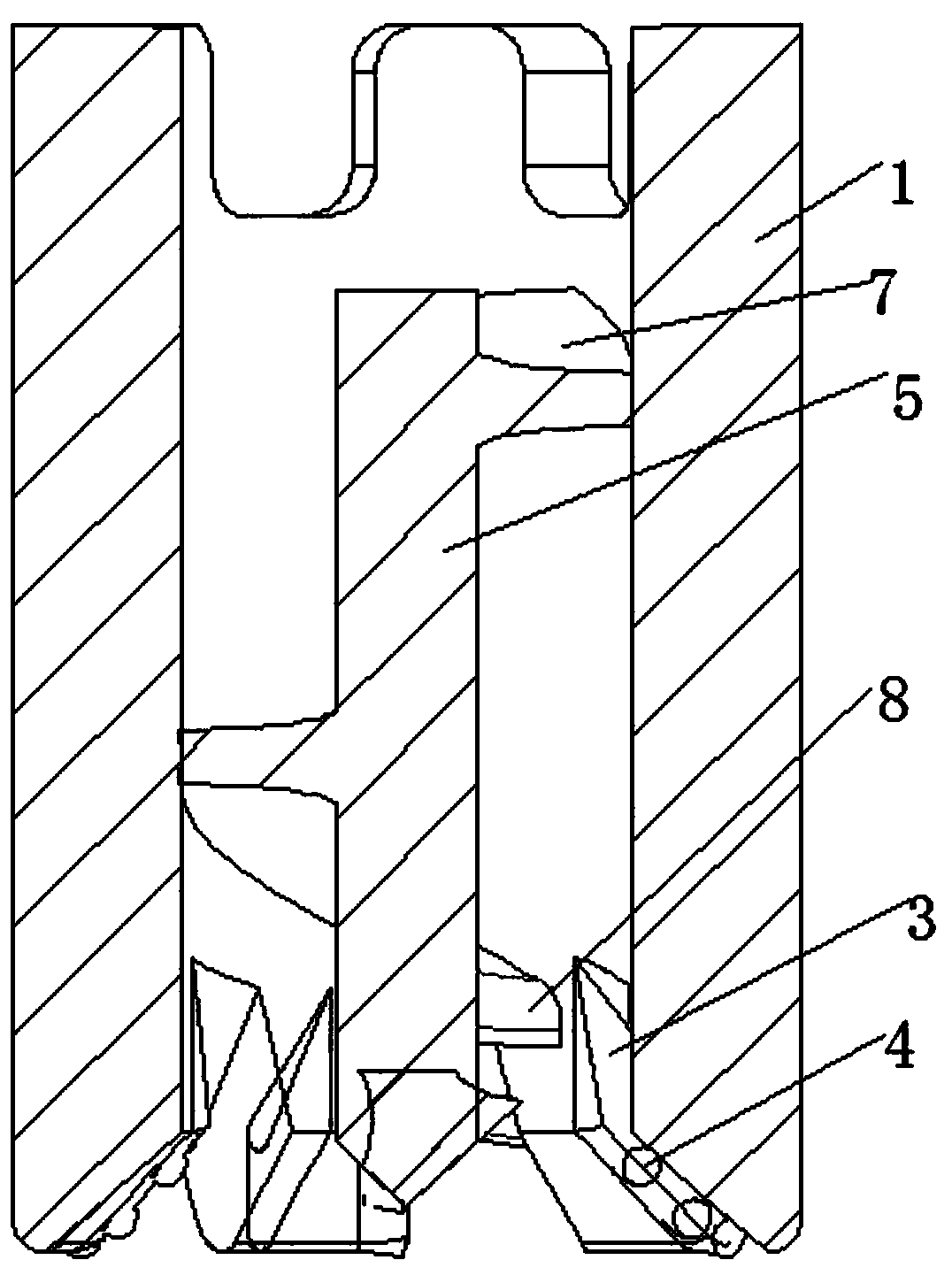

[0030] refer to figure 1 with image 3 , compared with Embodiment 1, the difference of this embodiment is: the dry drilling bit 1 drill bit end of the hollow cylindrical structure is distributed with a plurality of cutting blades 3 in the circumferential direction, and the cutting blades 3 are connected There are a plurality of cutting teeth 4, the cutting blade 3 is a cutting blade with an angle of 10°~60°, the side wall of the cutting blade and the end of the dry drill bit 1 form a side inclination angle along the circumferential direction, and the inclination angle is 5°~ 60°.

[0031] In actual use: a dry drilling bit 1 with a hollow cylindrical structure is distributed with multiple cutting blades 3 in the circumferential direction at one end of the drill bit, and the multiple cutting blades 3 are used for cutting rock formations, and multiple cutting teeth are connected to the cutting blades 3 4. A plurality of cutting teeth 4 increases the friction during cutting to i...

Embodiment 3

[0033] Compared with Embodiment 2, the difference of this embodiment lies in that: 4-12 cutting blades 3 are distributed in the circumferential direction of one end of the hollow cylindrical dry drilling bit 1 .

[0034] Preferably, there are six cutting blades 3 distributed in the circumferential direction of one end of the hollow cylindrical dry drilling bit 1 , and three cutting teeth 4 are connected to the cutting blades 3 .

[0035] In actual use: the dry drilling bit 1 with a hollow cylindrical structure has 4-12 cutting blades 3 distributed in the circumferential direction at one end, all of which are suitable for drilling in the surface layer with low requirements for drilling speed and soft lithology. The dry drilling bit 1 with a hollow cylindrical structure has six cutting blades 3 distributed in the circumferential direction at one end, and three cutting teeth 4 are connected to the cutting blades 3, so that the cutting efficiency is high during surface drilling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com