Splicing anti-skid floor

A non-slip floor and splicing technology, which is applied in the direction of elastic floor, floor, covering/lining, etc., can solve the problems of non-waterproof and anti-skid function, inconvenient installation of the floor, etc., and achieve simple structure, simplified installation process and increased friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

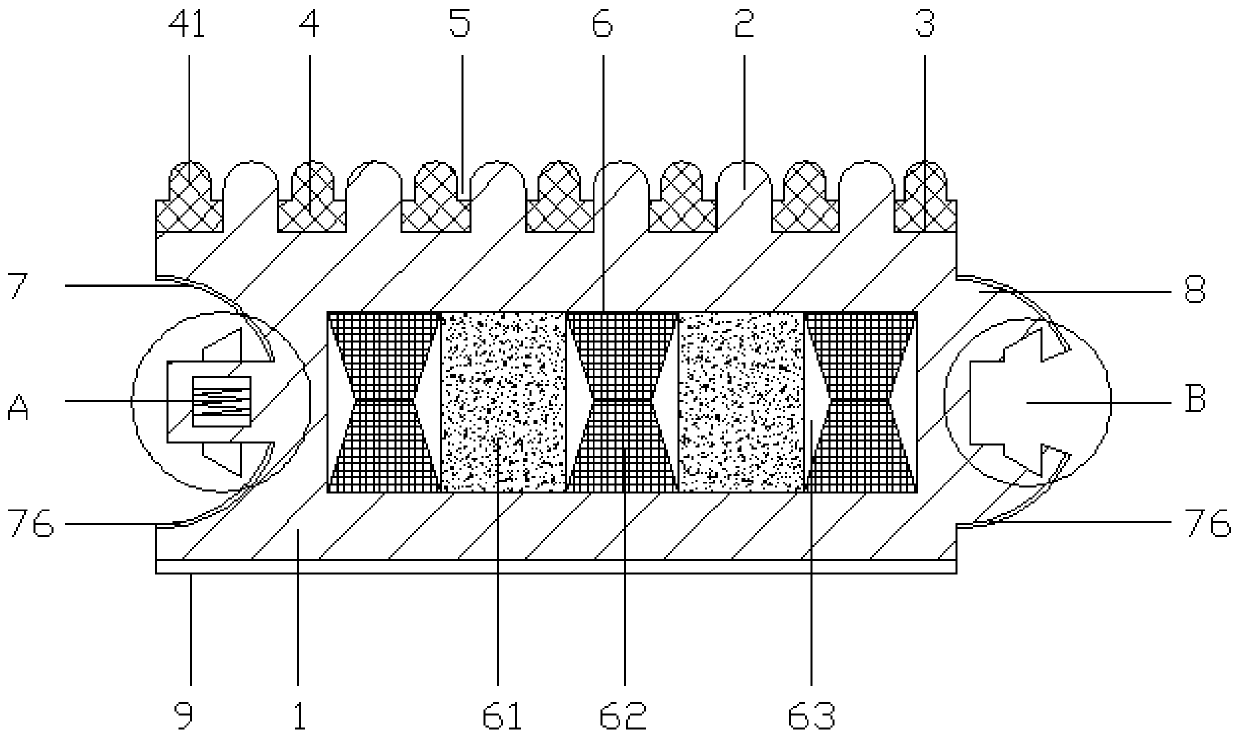

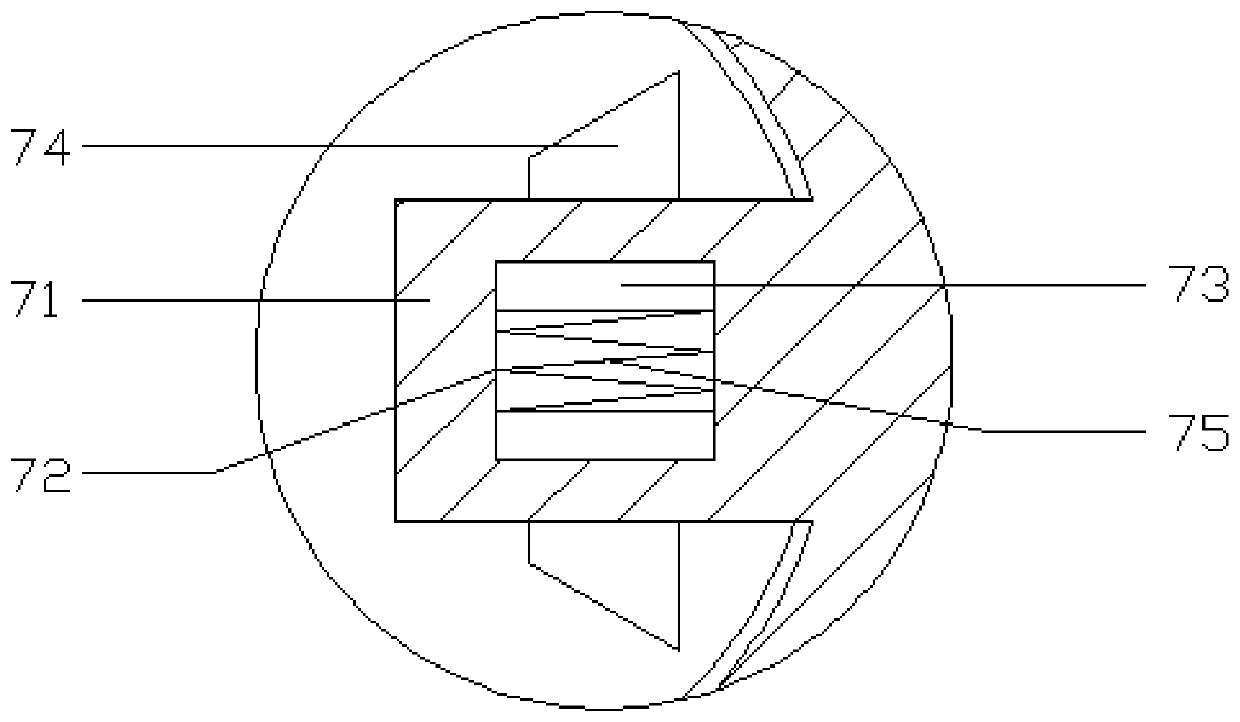

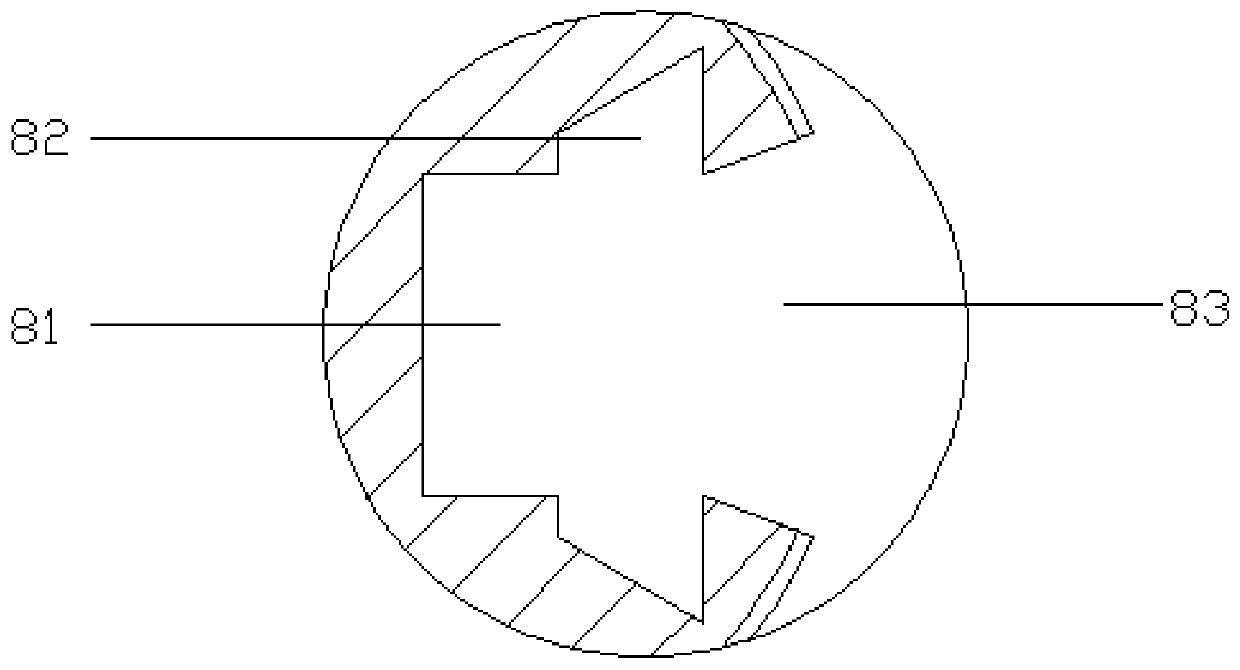

[0019] Referring to the accompanying drawings, a spliced anti-slip floor according to the present invention includes a floor body 1, a surface boss 2, an anti-slip mat installation groove 3, an anti-slip mat 4, a water guide groove 5, a middle groove 6, a first splicing end 7, and a second splicing end. end 8 and bottom protective layer 9, the top of the floor main body 1 is provided with several surface bosses 2, and anti-slip mat installation grooves 3 are arranged between each of the surface bosses 2, and the anti-skid mat installation grooves 3 are provided with Anti-slip mat 4, the top of the anti-slip mat 4 is provided with an anti-slip protrusion 41, a water guide groove 5 is provided between the anti-slip protrusion 41 and the surface protrusion 2, and a middle groove 6 is provided inside the floor main body 1, The left side wall of the floor body 1 is provided with a first splicing end 7, and the right side wall of the floor body 1 is provided with a second splicing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com