Method for alleviating scaling of pre-polymerization tower

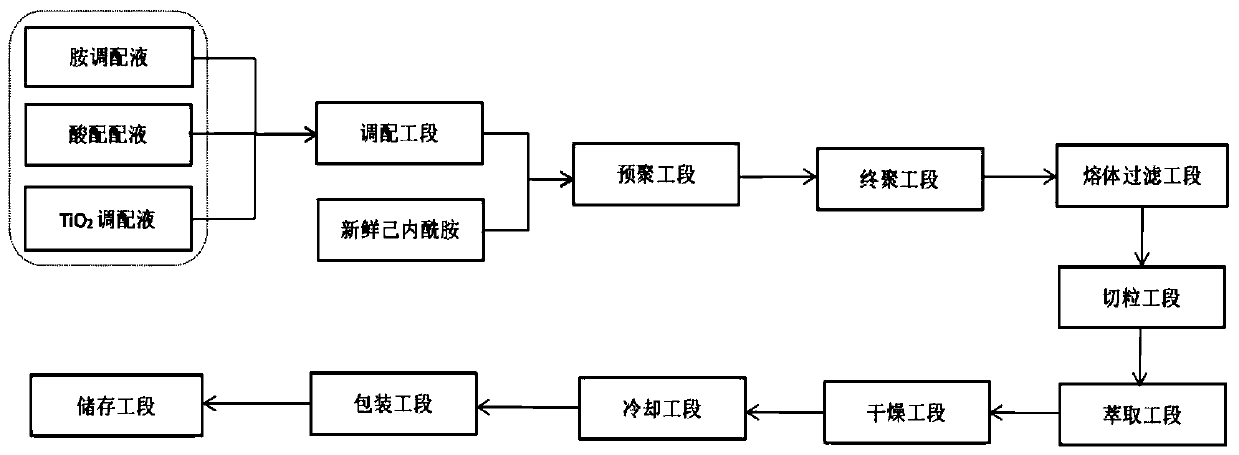

A pre-polymerization and polymerization technology, applied in the field of fiber polymerization, can solve the problems of poor particle compactness, fouling of polymerization towers, and prone to coagulation, etc., and achieves the effects of good compactness, extended replacement cycle, and alleviation of fouling phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

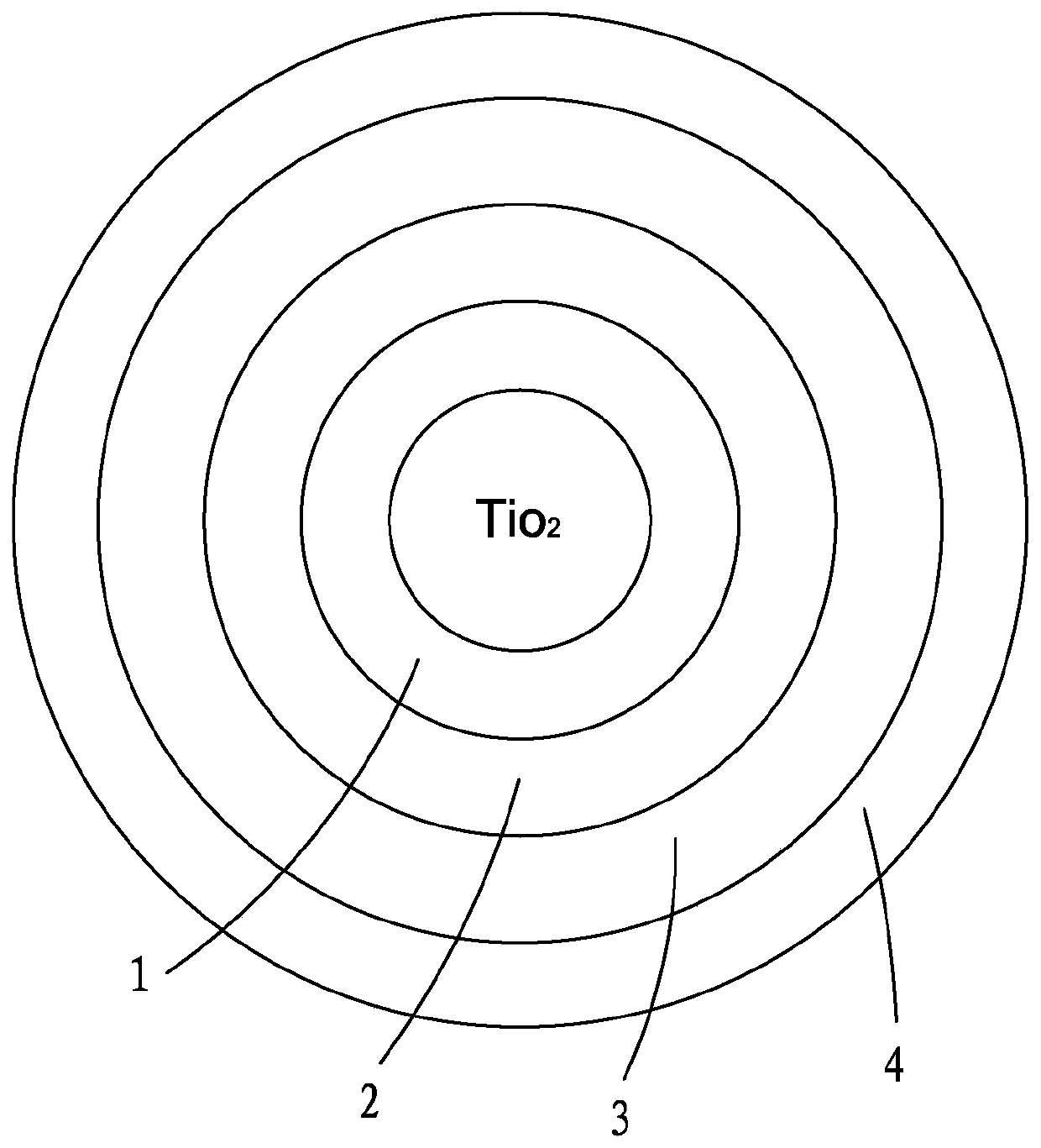

[0028] see figure 1 As shown, the present invention first provides a modified titanium dioxide matting agent, which includes titanium dioxide particles and a composite layer coated on the titanium dioxide particles. , aluminum oxide layer 3 and silicone polymer coating 4.

[0029] In the present invention, silica is coated on the innermost layer to avoid SiO 2 dissociated, and coated with TiO 2 The higher the silicon content, the more free SiO 2 the more. In the extraction tower, when the polyamide fiber slice monomer is extracted, silicon ions are dissolved in the extraction water, and then scaling and pipeline blockage occur during the recovery and treatment process of the extraction water, that is, the three-effect evaporation and concentration extraction water section. The element separation tank is fouled, resulting in major anomalies.

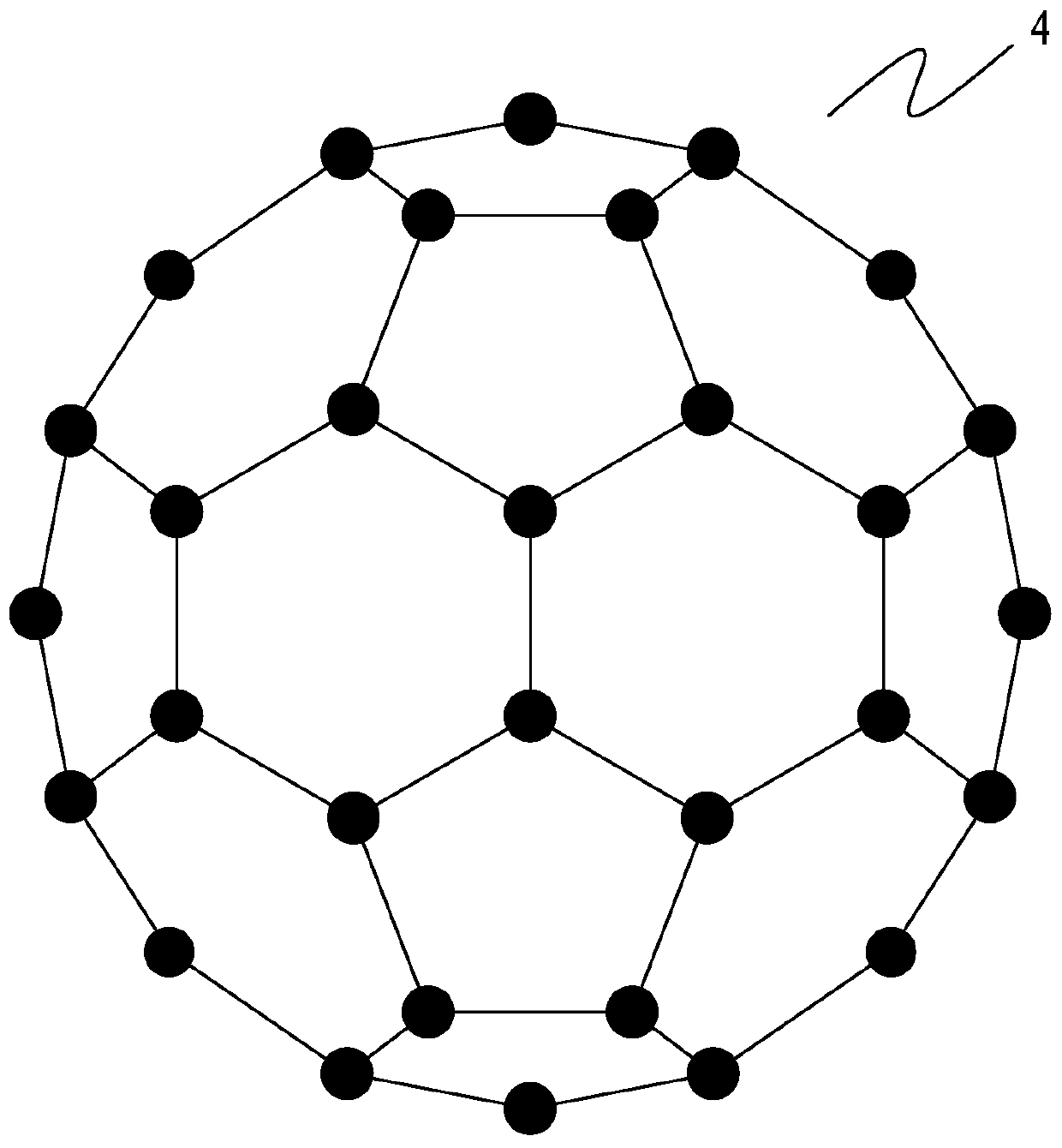

[0030] The organosilicon polymer layer 4 is an organosiloxane polymer layer, which is covered on the surface of the particles in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com