Mechanical-based heat treatment device for flanged steel pot products

A technology for heat treatment devices and steel pots, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of breakdown in the flanging area, affect product quality, and different distances, and achieve the effect of improving the functional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

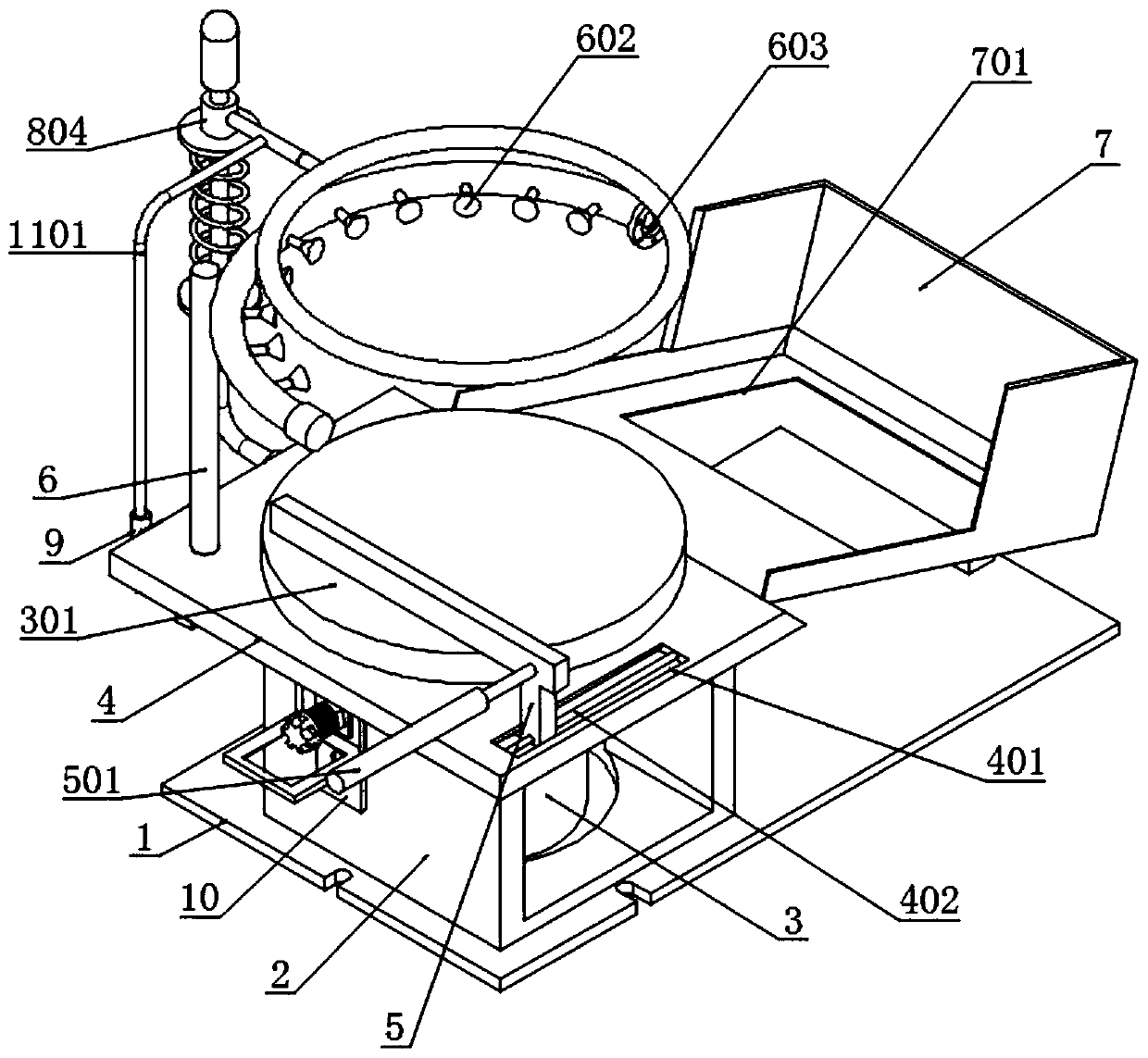

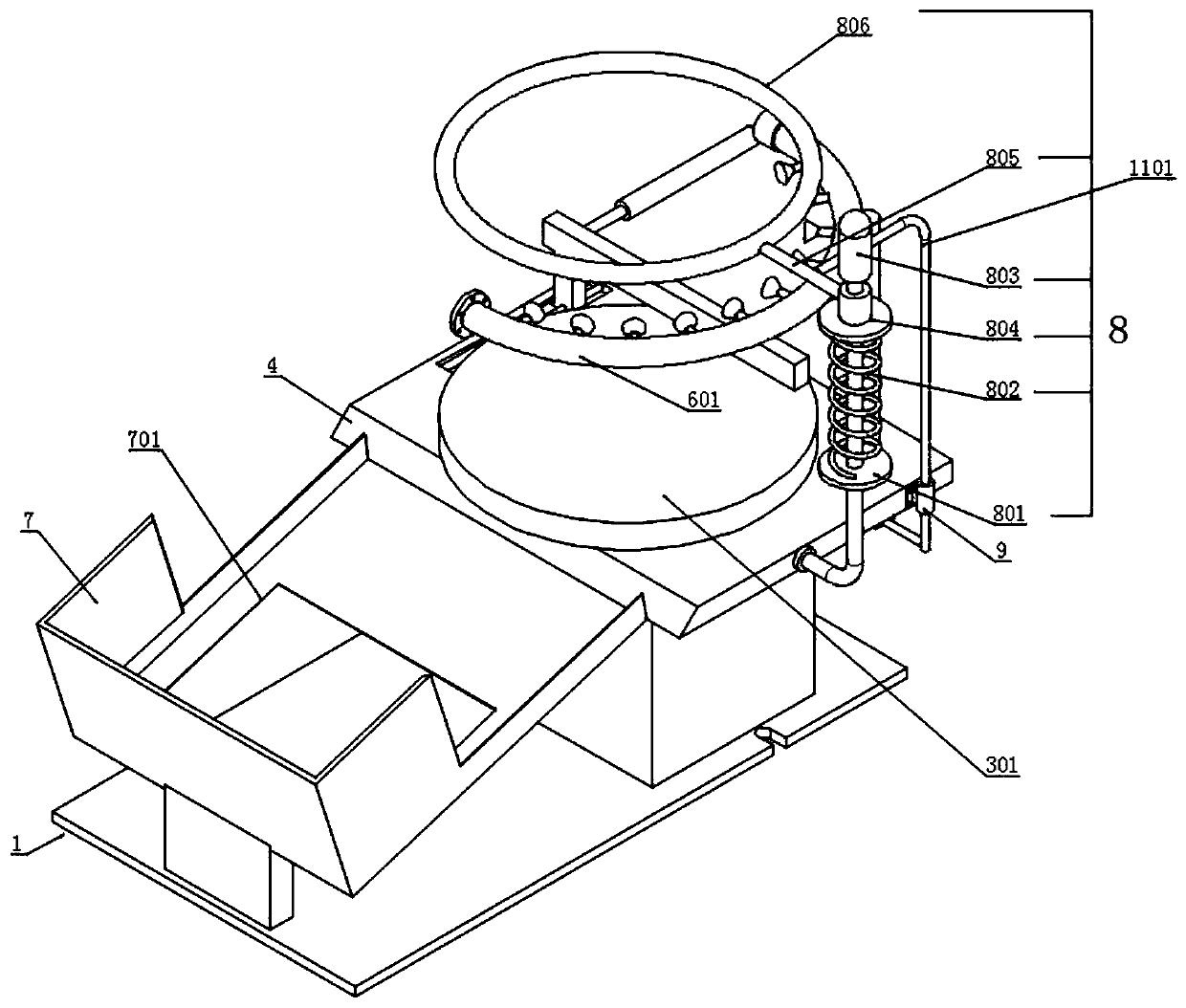

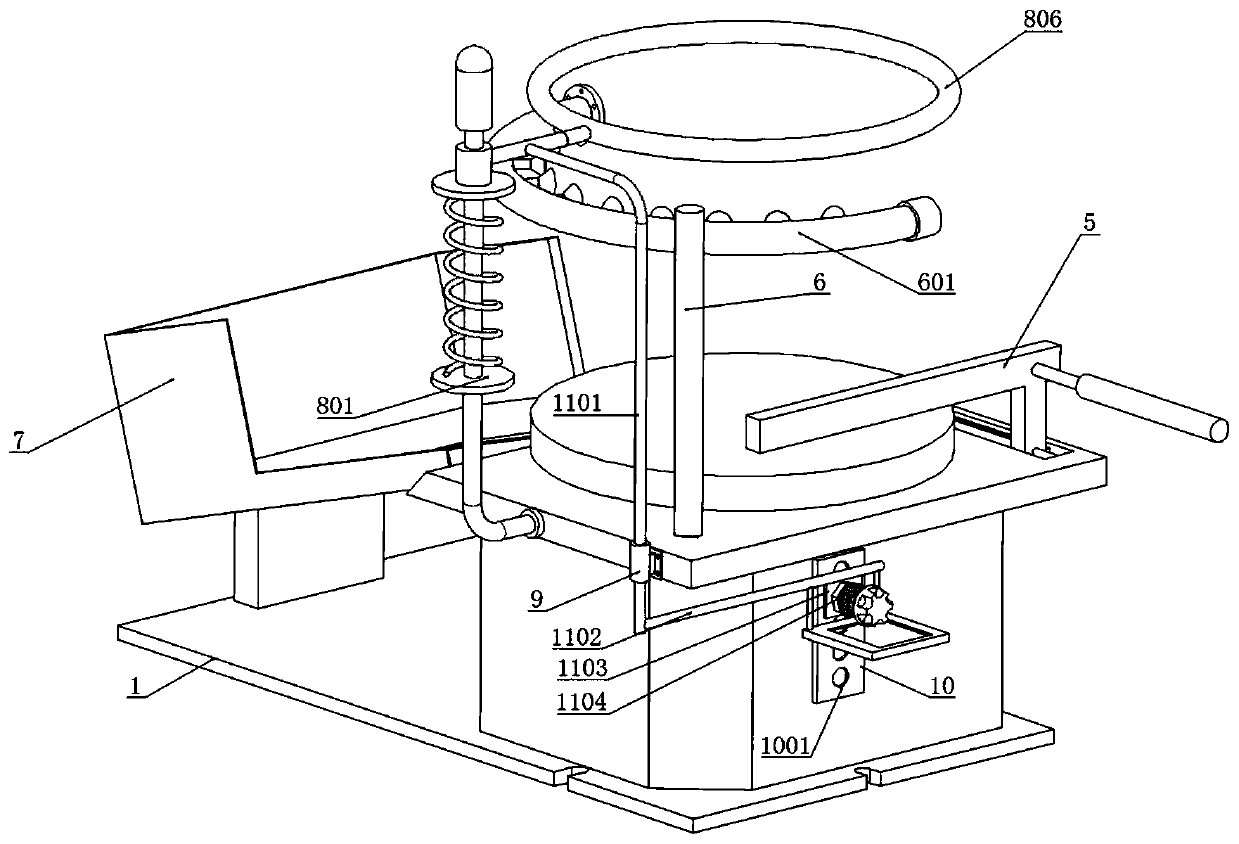

[0026] see Figure 1 to Figure 9 , a kind of embodiment that the present invention provides: based on the heat treatment device of the steel pan product processing flanging of machine, comprise bottom plate 1, regulating plate 10 and pressing mechanism 11; The top surface of the vertical compartment 2 supports the top seat 4 welded with a rectangular plate structure, and a sliding material seat 7 is installed on the right side of the top surface of the bottom plate 1 through a vertical welding plate; the front side of the vertical compartment 2 is provided with a rectangular storage chamber , a slow motor 3 is installed in its storage cavity, the rotation axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com