An organic optoelectronic device

An optoelectronic device and organic technology, applied in the field of organic optoelectronic devices, can solve the problems of short burnout time, screen burnout, OLED screen burnout, etc., and achieve the effect of improving service life and improving bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

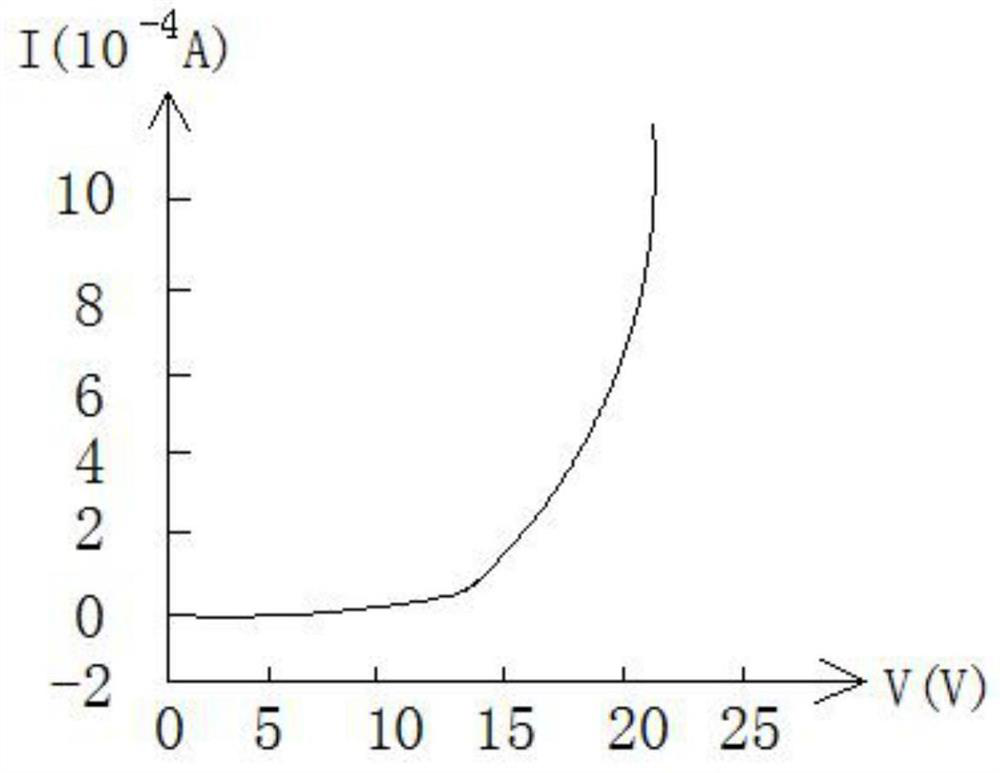

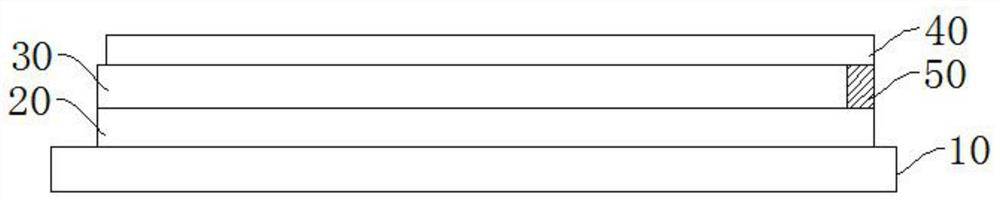

[0038] Please refer to figure 2 , this embodiment provides an organic optoelectronic device, comprising a substrate 10, and a first electrode layer 20, an organic functional layer 30 and a second electrode layer 40 formed on the substrate 10 in sequence; the first electrode layer 20 and Between the second electrode layers 40, an over-electricity confinement layer 50 is arranged in parallel with the organic functional layer 30, and the material of the over-electricity confinement layer 50 is a pressure-sensitive material.

[0039] The over-electric confinement layer, its varistor voltage V 压敏 with the safe voltage V of organic optoelectronic devices 安全 The relationship is as follows:

[0040] V 压敏 =k*V 安全, k is a constant between 0.7-1.3;

[0041] where the safety voltage V 安全 It is set according to different device structures, which is generally related to the operating voltage V of the organic optoelectronic device. 0 The following relationship is satisfied between: ...

Embodiment 2

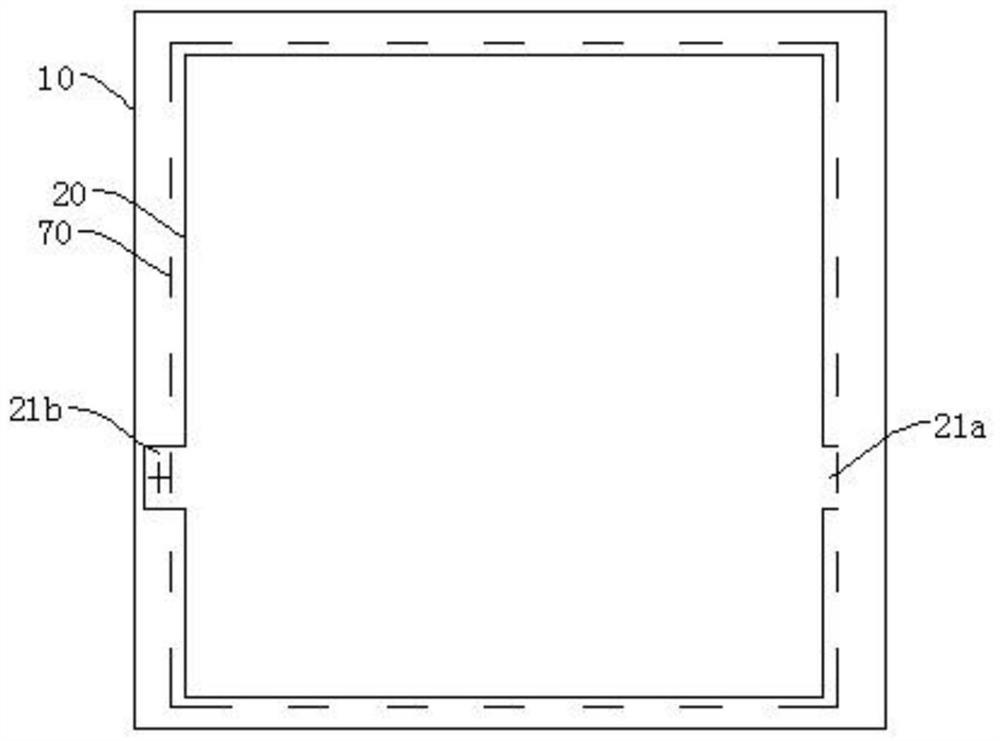

[0082] On the basis of Example 1, the implementation of the over-electricity confinement layer 50 in this example is replaced by: directly using the insulating region in the organic optoelectronic device to realize, specifically:

[0083] like Figure 15 As shown, taking the OLED screen as an example, in the structure of the OLED device, an insulating region 60 is provided between the first electrode layer 20 and the second electrode layer 40; the insulating region 60 is formed on the first electrode layer 40. On the electrode layer 20 and it isolates the pixel area on the first electrode layer 20, the organic functional layer 30 is located in the pixel area; the insulating area 60 is used to isolate the first electrode layer 20 and the second electrode layer 40 is also used to isolate adjacent pixels; it is generally selected from organic materials, such as phenolic resin, polyimide, etc.; in this embodiment, the material of the entire area of the insulating region 60 is di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com