A kind of PBT permanent antistatic material and its preparation method and application

An antistatic and conductive technology, which is applied in the field of PBT permanent antistatic materials and its preparation, can solve problems such as hazards, poor low-temperature impact toughness, and difficulty in controlling static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

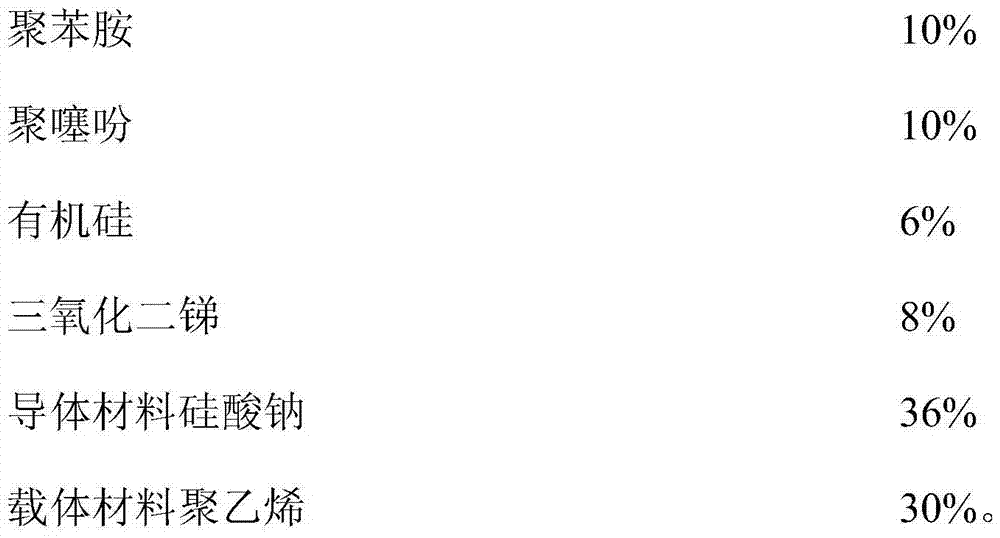

[0048] In this embodiment, the PBT antistatic material is prepared from the following raw materials:

[0049] PBT80%

[0050] Flame retardant conductive static dissipative masterbatch 20%

[0051] Among them, the flame retardant conductive static dissipative masterbatch is prepared from the following raw materials:

[0052]

[0053] The preparation method of PBT antistatic material is as follows:

[0054] A. Add polyaniline, polythiophene, silicone, conductive material and polyethylene into the mixer, the stirring speed is 20r / min, and blend and dope for 30min to obtain the mixed material; add the mixed material to the twin-screw extruder Medium-extrusion granulation, the preheating temperature in the screw area of the extruder is 180°C, and the screw speed is 320r / min, to obtain a flame-retardant, conductive and static-dissipative masterbatch;

[0055] B. Blending PBT and flame retardant conductive static dissipative masterbatch, the stirring rate during blending is 1...

Embodiment 2

[0057] In this embodiment, the PBT antistatic material is prepared from the following raw materials:

[0058] PBT75%

[0059] Flame retardant conductive static dissipative masterbatch 25%

[0060] Among them, the flame retardant conductive static dissipative masterbatch is prepared from the following raw materials:

[0061]

[0062] The preparation method of PBT antistatic material is as follows:

[0063] A. Add polyaniline, polythiophene, silicone, conductive material and polyethylene into the mixer, the stirring speed is 90r / min, and blend and dope for 10min to obtain the mixed material; add the mixed material to the twin-screw extruder Medium-extrusion granulation, the preheating temperature in the screw area of the extruder is 250°C, and the screw speed is 190r / min, to obtain a flame-retardant, conductive and static-dissipative masterbatch;

[0064] B. Blending PBT and flame retardant conductive static dissipative masterbatch, the stirring rate during blending is 2...

Embodiment 3

[0066] In this embodiment, the PBT antistatic material is prepared from the following raw materials:

[0067] PBT95%

[0068] Flame retardant conductive static dissipative masterbatch 5%;

[0069] Among them, the flame retardant conductive static dissipative masterbatch is prepared from the following raw materials:

[0070]

[0071] The preparation method of PBT antistatic material is as follows:

[0072] A. Add polyaniline, polythiophene, silicone, conductive material and polyethylene into the mixer, the stirring speed is 50r / min, and blend and dope for 15min to obtain the mixed material; add the mixed material to the twin-screw extruder Medium-extrusion granulation, the preheating temperature in the screw area of the extruder is 200°C, and the screw speed is 220r / min, to obtain a flame-retardant, conductive and static-dissipative masterbatch;

[0073] B. Blending PBT and flame-retardant, conductive and static-dissipative masterbatch, the stirring rate during blending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com