Synthetic method for improving yield of methamidophos intermediate

A synthetic method, the technology of methamidophos, applied in the field of fine chemical production, can solve the problem of not exceeding 75%, and achieve the effect of improving quality standards and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

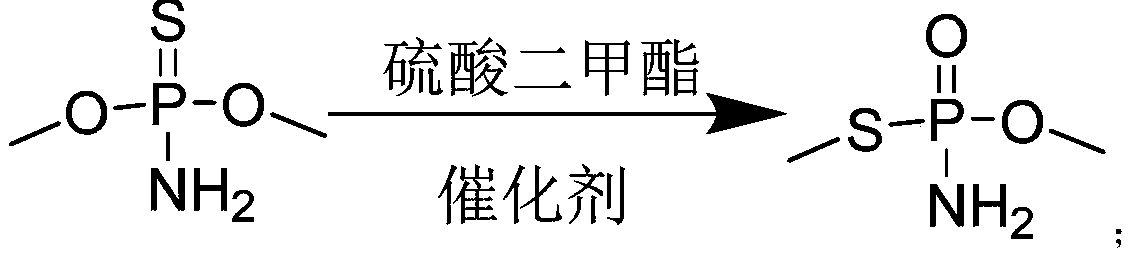

Method used

Image

Examples

Embodiment 1

[0020] A kind of synthetic method that is used to improve the productive rate of methamidophos intermediate, it comprises getting O, O-dimethyl thiophosphoramide (spermine for short) 148g (1mol), methylene dichloride 15g, catalyzer methyl iodide 0.2g Put it into a 250mL reaction bottle, add 12.6g of dimethyl sulfate (0.1mol) dropwise, control the reaction temperature at 45-50°C, stir and react for 5 hours to obtain methamidophos with a content of 73.4% and a reaction yield of 92.7%.

Embodiment 2

[0022] A kind of synthetic method that is used to improve the productive rate of methamidophos intermediate, it comprises getting O, O-dimethyl phosphorothioate (spermine for short) 148g (1mol), chloroform 25g, catalyst methyl methanesulfonate 0.1 g was put into a 250mL reaction bottle, 12.6g of dimethyl sulfate was added dropwise, the reaction temperature was controlled at 35-40°C, and the reaction was stirred for 4 hours to obtain methamidophos with a content of 73.4% and a reaction yield of 96.8%.

Embodiment 3

[0024] A kind of synthetic method that is used to improve the productive rate of methamidophos intermediate, it comprises getting O, O-dimethyl thiophosphoramide (spermine for short) 148g (1mol), carbon tetrachloride 35g, catalyst trifluoroform Put 0.05 g of methyl sulfonate into a 250 mL reaction flask, add 12.6 g of dimethyl sulfate dropwise, control the reaction temperature at 30-35°C, and stir for 3 hours to obtain methamidophos with a content of 70.4% and a reaction yield of 97.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com