A high-frequency high-impedance iron-poor manganese-zinc ferrite and its preparation method

A manganese-zinc ferrite, high-impedance technology, applied in the direction of inorganic material magnetism, etc., can solve the problems of low saturation magnetic induction and Curie temperature, limited anti-EMI ability, low impedance, etc., to achieve high magnetic permeability, Good high impedance performance, the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

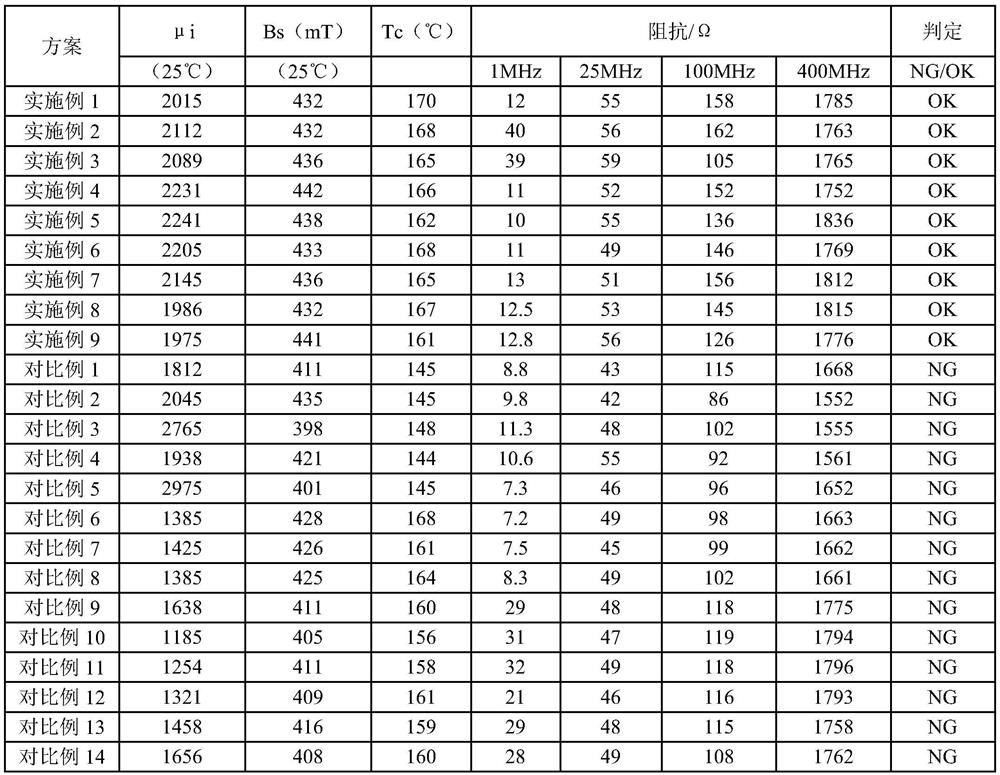

Examples

Embodiment 1

[0041] A method for preparing a high-frequency and high-impedance poor iron-manganese-zinc ferrite, comprising the steps of:

[0042] (1) Ingredients and sanding: weigh 48.6% Fe by mole percentage 2 O 3 , 32.8% MnO, 17.5% ZnO and 1.1% Co 2 O 3 Four main components, put into a sand mill, add deionized water for mixing and crushing for 40 minutes, and then spray and granulate to obtain spray material after uniform mixing;

[0043] (2) Pre-sintering: put the spray material into the pre-sintering furnace of the rotary kiln, and carry out pre-sintering at 800 ° C to obtain the pre-sintering material, and the feeding amount is 250kg / h;

[0044] (3) Secondary sanding: Add additive to pre-sintered material: 50ppm SiO 2 , 500ppm CaCO 3 , 200ppm Bi 2 O 3 , 200ppm ZrO 2 , 400ppm TiO 2 , and then add deionized water and put it into a sand mill for secondary sand grinding to obtain secondary sand abrasive. ;

[0045] (4) Spray granulation and molding: add 0.08wt% of PVA by weigh...

Embodiment 2

[0052] A method for preparing a high-frequency and high-impedance poor iron-manganese-zinc ferrite, comprising the steps of:

[0053] (1) Ingredients and sanding: weigh 47.8% Fe by mole percentage 2 O 3 , 36% MnO, 15% ZnO and 1.2% Co 2 O 3 The four main components are put into a sand mill and deionized water is added for mixing and crushing for 30 minutes. After uniform mixing, spray granulation is carried out to obtain a spray material;

[0054] (2) Pre-sintering: put the spray material into the pre-sintering furnace of the rotary kiln, and carry out pre-sintering at 750 ° C to obtain the pre-sintering material, and the feeding amount is 200 kg / h;

[0055] (3) Secondary sanding: Add additive to pre-sintered material: 10ppm SiO 2 , 200ppm CaCO 3 , 100ppm Bi 2 O 3 , 100ppm ZrO 2 , 100ppm TiO 2 , and then add deionized water and put it into a sand mill for secondary sanding to obtain secondary sand abrasives. The feeding amount is 200kg / h (calculated as dry powder), and...

Embodiment 3

[0063] A method for preparing a high-frequency and high-impedance poor iron-manganese-zinc ferrite, comprising the steps of:

[0064] (1) Ingredients and sanding: weigh 49.8% Fe by mole percentage 2 O 3 , 31% MnO, 18.5% ZnO and 0.7% Co 2 O 3 The four main components are put into a sand mill and deionized water is added for mixing and crushing for 50 minutes. After uniform mixing, spray granulation is carried out to obtain a spray material;

[0065] (2) Pre-sintering: put the spray material into the pre-sintering furnace of the rotary kiln, and carry out pre-sintering at 900 ° C to obtain the pre-sintering material, and the feeding amount is 300 kg / h;

[0066] (3) Secondary sanding: Add additives to the pre-sintered material: 100ppm SiO 2 , 1000ppm CaCO 3 , 300ppmBi 2 O 3 , 300ppm ZrO 2 , 600ppm TiO 2 , and then add deionized water and put it into a sand mill for secondary sanding to obtain secondary sand abrasives. The feed amount is 250kg / h (calculated as dry powder)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com