Stone mastic asphalt mixture using recycled fan blade waste as filler

A technology of asphalt mastic and fan blades, which is applied in the field of material science and engineering, can solve problems such as environmental pollution, and achieve the effects of reducing costs, good application prospects and improving comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

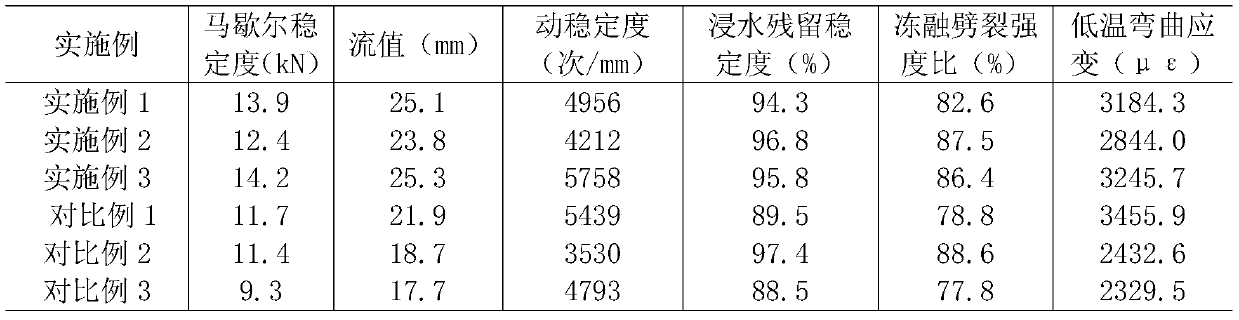

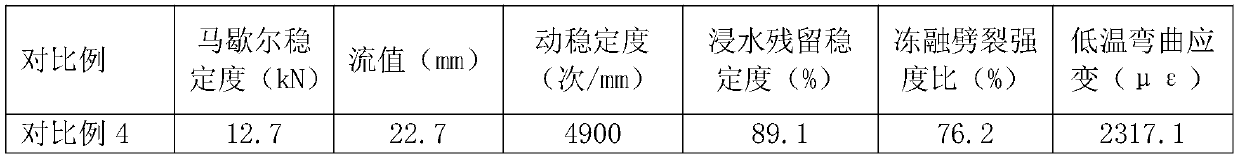

Examples

preparation example Construction

[0034] The preparation process of the SBS modified asphalt is as follows: when the asphalt is heated to 120-150°C, the SBS modifier is added for stirring, and then heated continuously to 180-200°C to obtain the SBS modified asphalt. No. 90 asphalt is used. The addition amount of the SBS modifier is 5-9% of the asphalt mass.

[0035] This application selects fan waste with different particle sizes to replace aggregates in asphalt mastic gravel mixture: fan powder waste replaces crushed stones with a particle size of ≤0.075mm; Among the fiber waste, fan fiber waste is selected to replace lignin fiber as a stabilizer; fan block waste is used to replace gravel with a particle size > 9.5 mm.

[0036] The total amount of recycled fan blade waste accounts for 0.12% to 0.15% of the total mass of all materials.

[0037] The asphalt ratio of SBS modified asphalt and all materials is 5.00%-8.00%.

[0038] The present application also protects a preparation method of the above-mentioned...

Embodiment 1

[0043] In this embodiment, the asphalt mastic macadam mixture with recycled fan blade waste as filler, in parts by weight, includes the following components: 0.7kg of SBS modified asphalt, and the total mass of lignin fiber and fibrous waste is 0.8kg , crushed stone 10kg, fan powder waste 0.4kg, fan massive waste 0.2kg in total;

[0044] Fan powder waste replaces gravel with a particle size of ≤0.075mm; in the fiber waste with a particle size of >0.075mm and a particle size of ≤9.5mm, choose fan fiber waste to replace lignin fiber as a stabilizer; use fan block waste to replace Crushed stone with a particle size > 9.5mm.

[0045] The total amount of recycled fan blade waste accounts for 0.14% of the total mass of all materials.

[0046] The asphalt mastic macadam mixture adopts SMA-16 skeleton structure gradation,

[0047] The gradation of asphalt horseshoe grease mixture is as follows:

[0048] Mesh size(mm) 19 16 13.2 9.5 4.75 2.36 1.18 0.6 0.3 0.15 0....

Embodiment 2

[0055] The raw material selection and preparation method of the mixture in this example are the same as in Example 1, except that the mass ratio of lignin fiber and fan fiber waste added is 1:9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com