Heavy oil recovery method

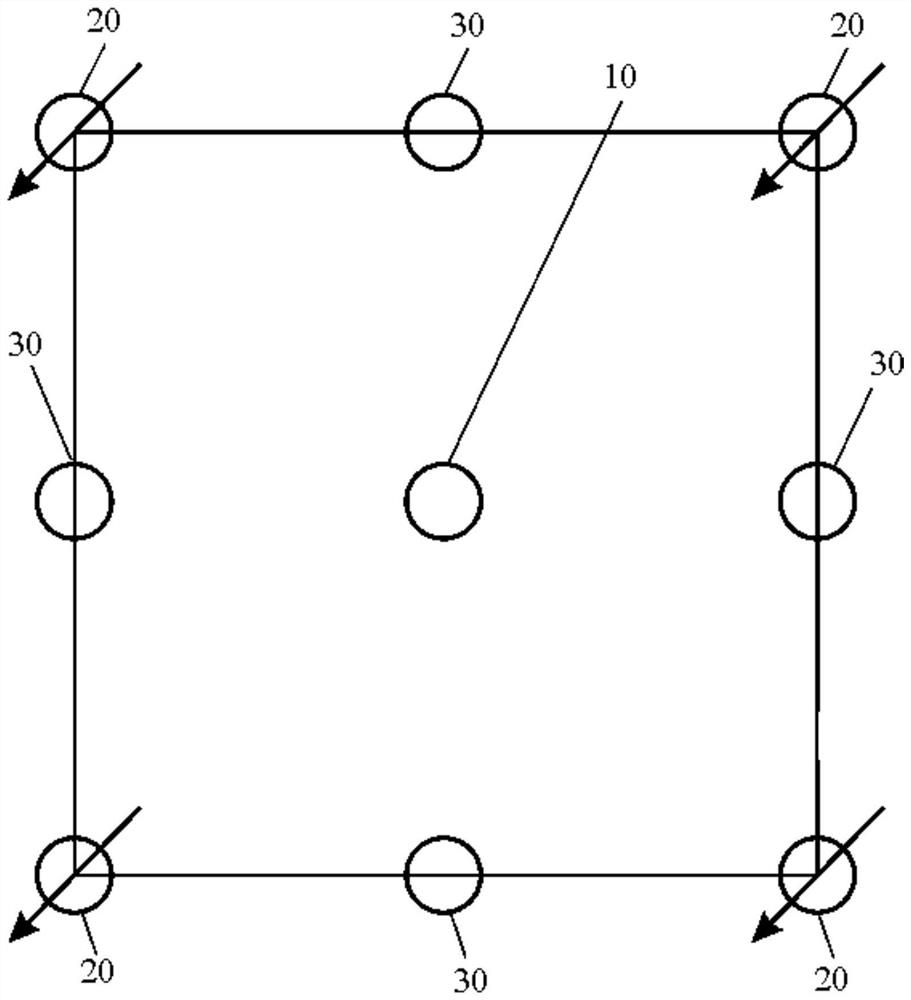

A production method and heavy oil technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problem of low recovery rate of reverse nine-point well pattern, so as to improve production degree and recovery rate , to solve the effect of low recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the present invention, unless otherwise stated, the orientation words used such as "upper, lower" are usually directed to the accompanying drawings

[0031] The technical solution of this embodiment is applied to disconnect the first vertical well 10 from the gas supply device, so as to connect the first vertical well 10 to the gas supply device.

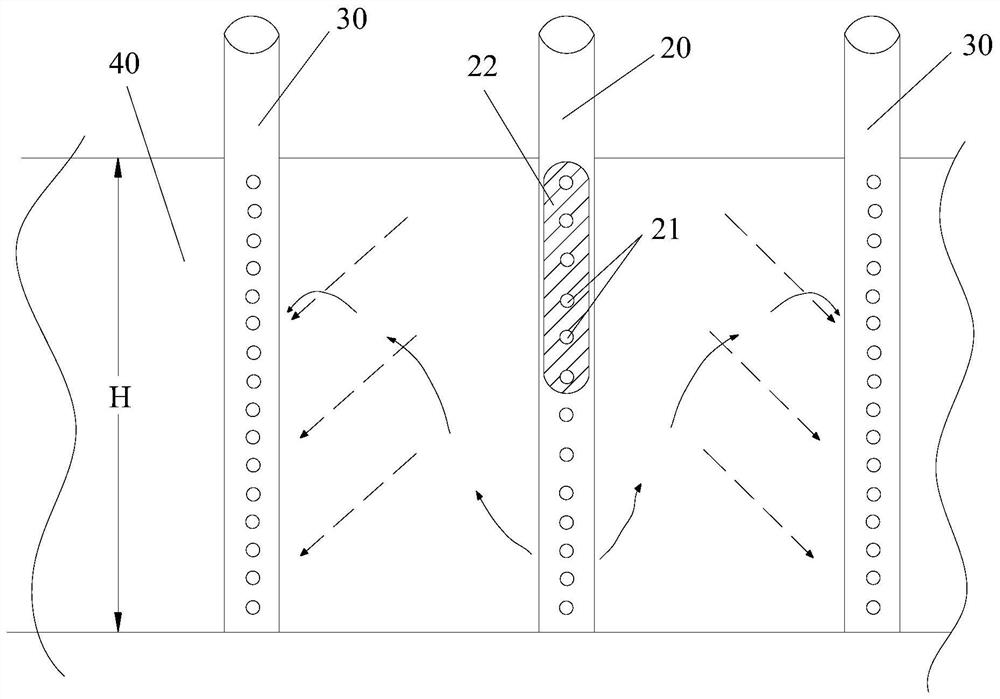

[0034] In this embodiment, in the steam injection cycle of the gas supply device, the daily steam injection volume of the gas supply device is 2 to 3 tons per meter. This

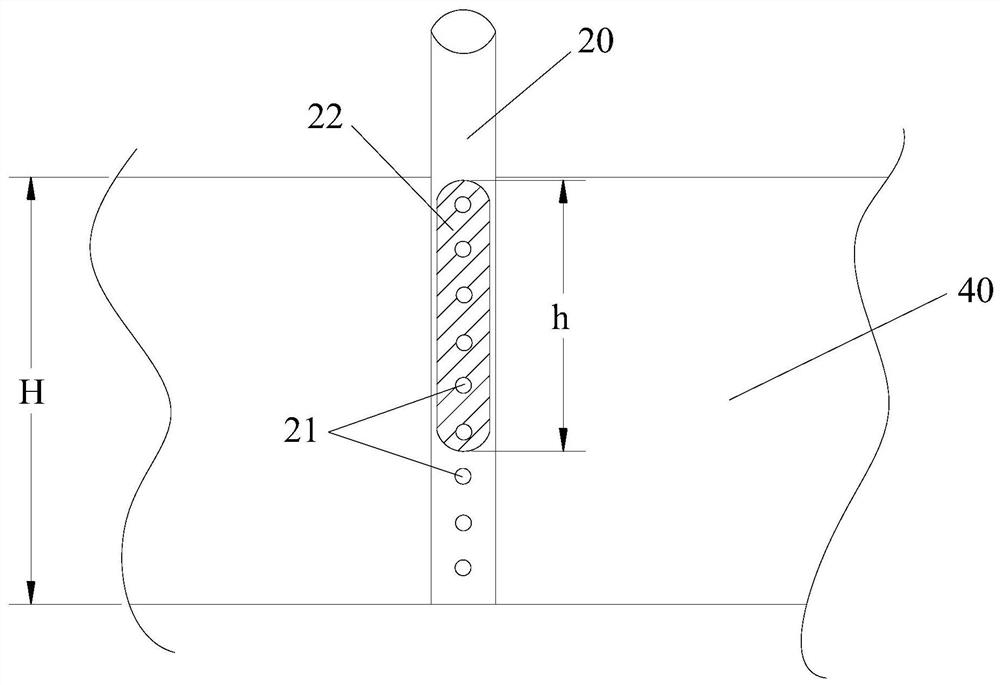

[0035] In this embodiment, the preset length h and the thickness H of the oil layer 40 satisfy 0.5H≤h≤0.6H. Thus, the above

[0036] Specifically, after the second vertical well 20 is disconnected from the oil production device, the upper end of the second vertical well 20 is blocked.

[0039] In this embodiment, the carbon dioxide gas injection amount of the gas supply device is 1.5 to 2.5 tons per meter. Specifically, if the oil layer 40

[0043] It sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com