Membrane stack capable of being automatically assembled and disassembled for treating radioactive wastewater

A radioactive wastewater, automatic loading and unloading technology, applied in the direction of radioactive pollutants, special treatment targets, water/sludge/sewage treatment, etc., can solve unfavorable installation, maintenance and membrane replacement, difficult infiltration and extravasation, membrane stack Performance degradation and other problems, to achieve the effect of promoting the application, less scrapped components, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

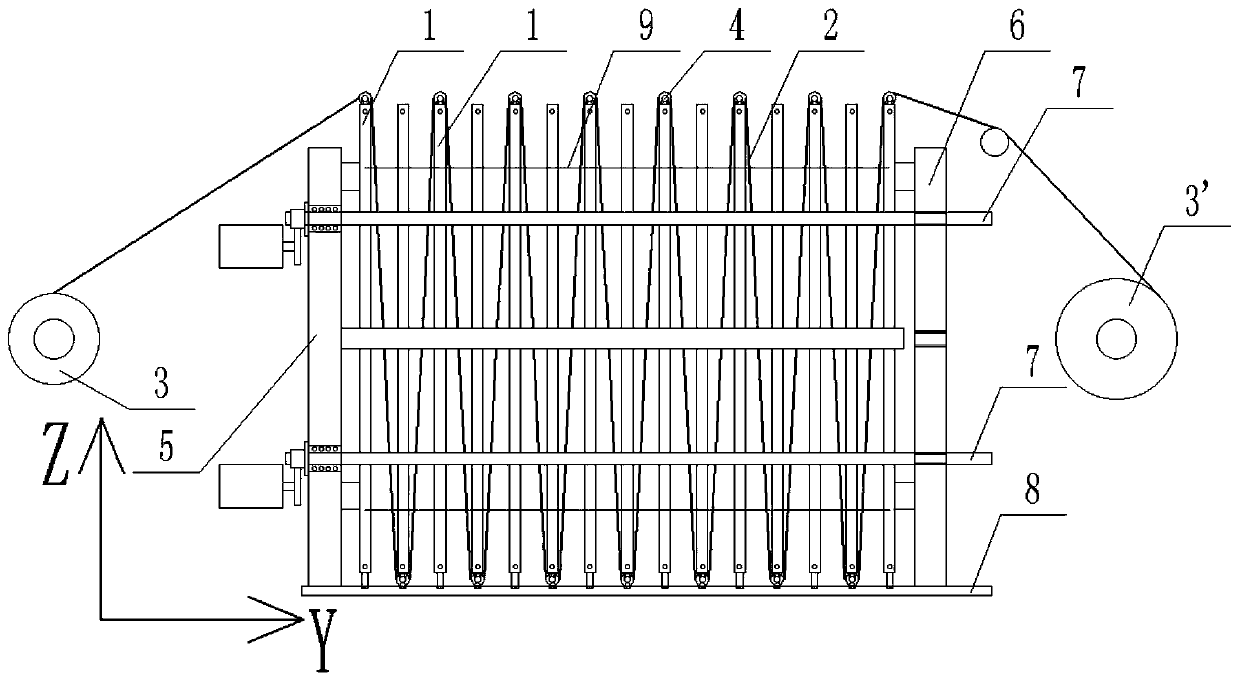

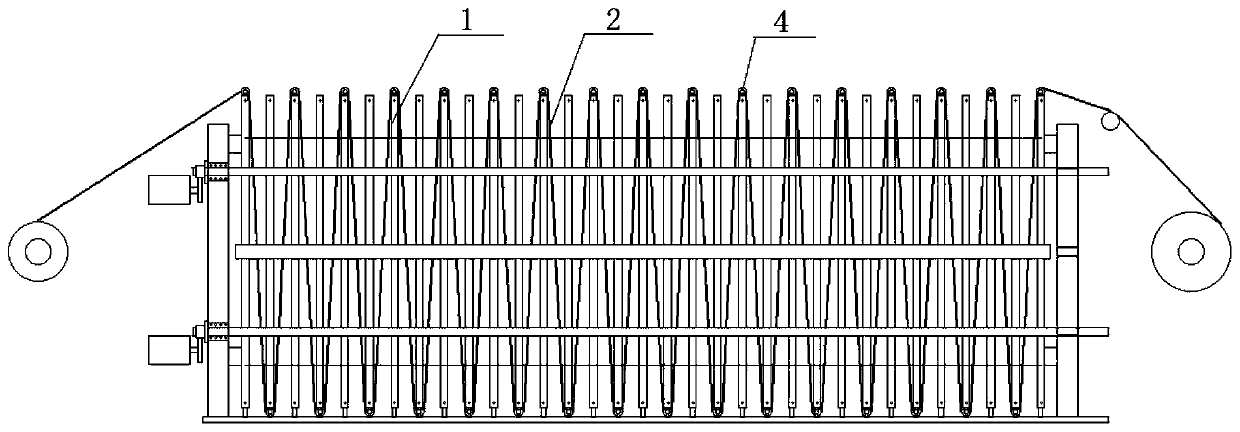

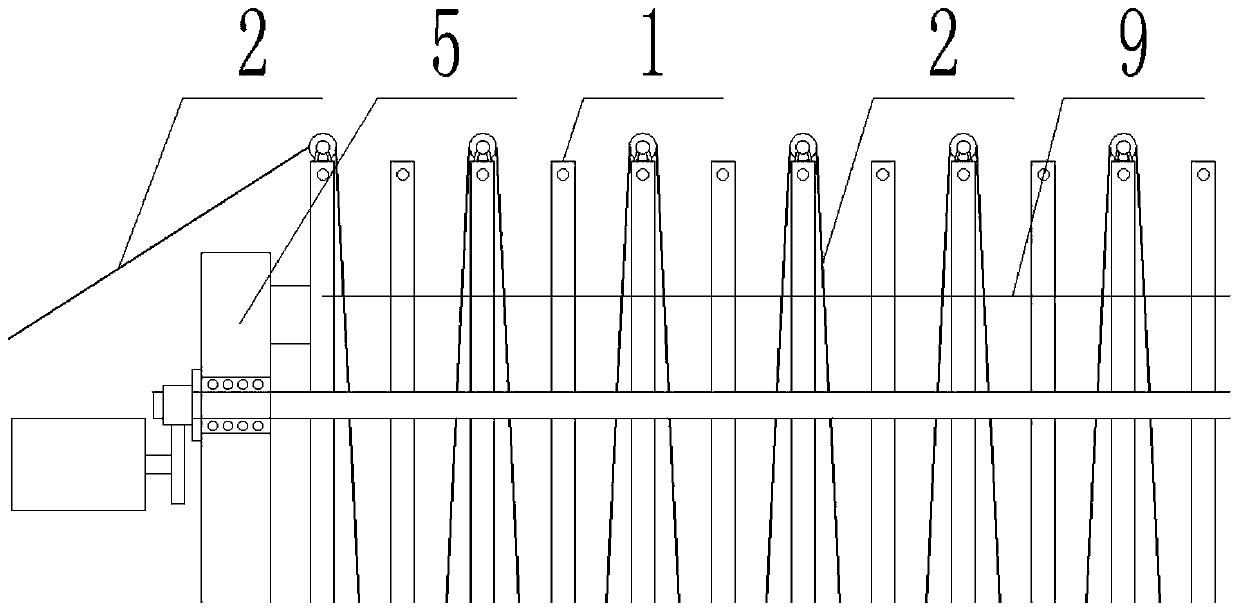

[0138] Embodiment 1 is used for the automatic loading and unloading of the membrane in the membrane stack of processing radioactive waste water

[0139] The membrane stack obtained above is used to treat radioactive wastewater, and the feed and discharge are shown in Figure 11(1), wherein the "original acid" is the treated water source, which is the high-acid and high-radioactive waste produced by the reprocessing of spent fuel. Waste liquid (that is, waste liquid containing high-concentration acid and high-radioactive substances), the composition of which is: nitric acid 7mol / l; U (uranium) content 1g / l, activity: >10 9 Bq / L, see "original acid" shown in Table 1 for details; in Figure 11(1), "cation" refers to "cation exchange membrane" (abbreviated as C membrane); between the dialysis chamber and the diffusion chamber are cations Exchange membrane, the "residual acid" is the acid obtained in the dialysis chamber, and the "acid generation" is the acid obtained in the "diffu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com