Bamboo tableware milling forming machine

A molding machine and tableware technology, which is applied in the field of mechanical processing, can solve the problems of troublesome feeding process, inability to move bamboo pieces, and achieve the effects of facilitating feeding, improving processing success rate, and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

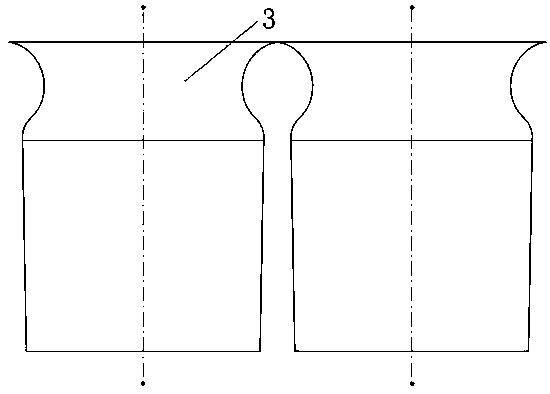

[0023] refer to Figure 1~3 : A milling and cutting machine for bamboo tableware, comprising a frame 1, a feed platform 2, a milling cutter 3 and a motor 4 driving the rotation of the milling cutter 3 are arranged on the frame 1, and the feed platform 2 and the milling cutter 3 move relatively The feeding platform 2 is provided with two clamping parts 21 for clamping a plurality of bamboo slices, at least one clamping part 21 is movably arranged on the feeding platform 2, and the movably provided clamping part 21 is used to increase or decrease The distance between the two clamping pieces 21 is that the clamping pieces 21 are movable on the feeding platform 2 through the cylinder 22; the profile of the clamping pieces 21 is the same as that of the bamboo tableware, and the distance between the two clamping pieces 21 is 15cm~30cm.

[0024] The line connecting the centers of the two clamping parts 21 is parallel to the tangent of the milling cutter 3 , and when the feed platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com