Oil dirt disposal system and process

A technology for disposal system and contamination, applied in the field of contamination treatment, can solve problems such as environmental pollution, and achieve the effect of reducing harmful effects, avoiding pollution and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

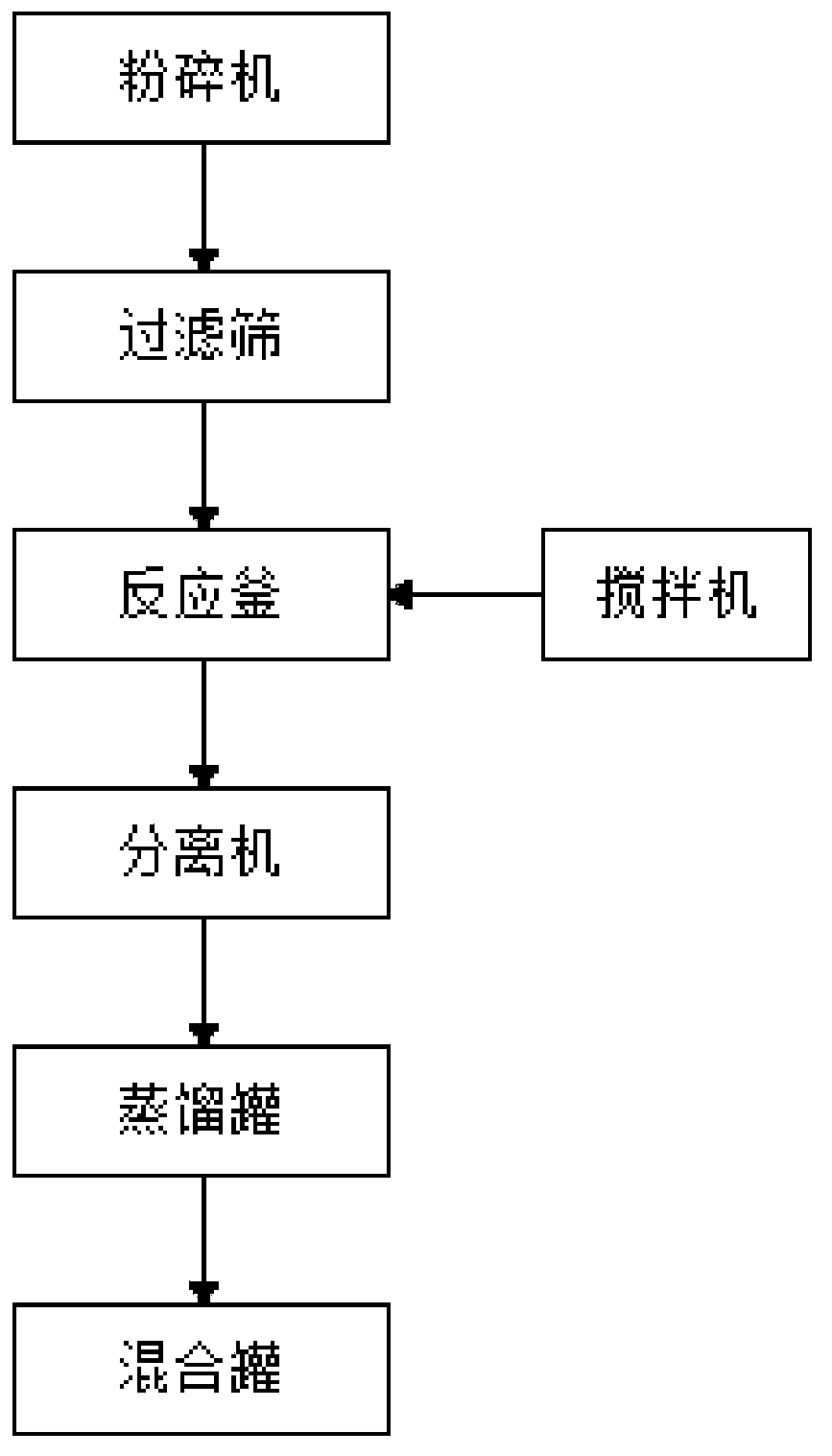

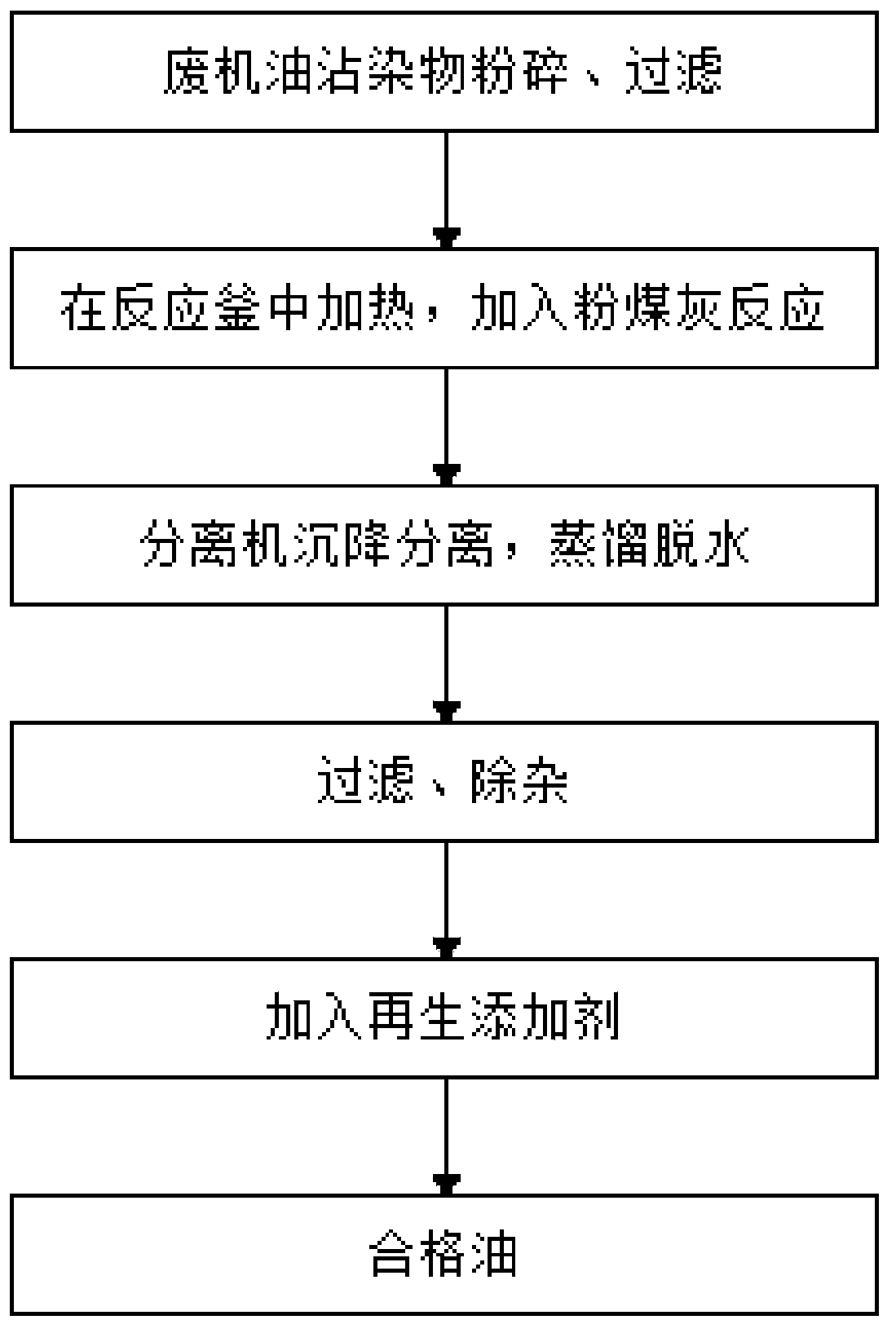

[0027] Such as figure 1 , figure 2 As shown, a kind of oil stain disposal system described in this embodiment includes a pulverizer, a filter screen, a reaction kettle, a separator, a distillation tank, and a mixing tank. The pulverizer is connected with the filter screen, and the filter screen is connected with the filter screen. The reaction kettle is connected, the reaction kettle is provided with a first adding device for adding fly ash, the reaction kettle is connected with the separator, the separator is connected with the distillation tank, the distillation tank is connected with the mixing tank, and the mixing tank is equipped with In the second adding device for adding regeneration additives, a stirrer is provided in the reaction kettle. Wherein, the filter sieve includes a primary filter sieve and a secondary filter sieve. The filter screen of the primary filter sieve is 30-70 mesh, and the filter screen of the secondary filter sieve is 220-350 mesh. Small particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com