Organic-inorganic hybrid fireproof coating and preparation method thereof

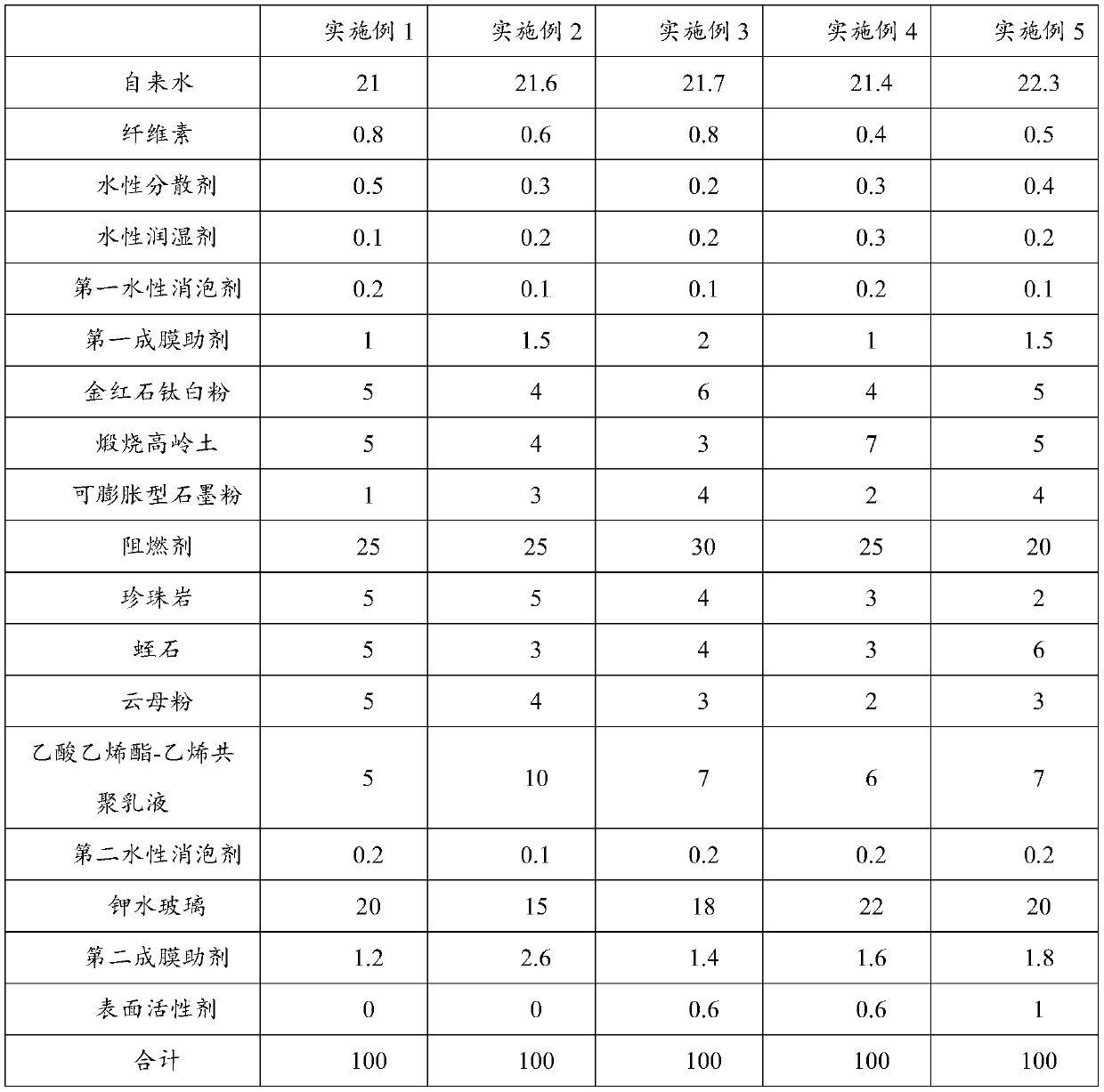

A kind of fire-proof coating, hybrid technology, applied in the direction of fire-proof coating, alkali metal silicate coating, coating, etc., can solve problems such as foaming, inorganic coating needs to be improved, whitening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The embodiment of the present application also provides a method for preparing the above-mentioned organic-inorganic hybrid fireproof coating, which includes the following steps:

[0044] S1. Add cellulose to part of the water, and stir at 800-1000 rpm until the cellulose is fully dissolved to form a cellulose solution.

[0045] S2. Add water-based dispersant, water-based wetting agent, water-based defoamer, film-forming aid, and water to the cellulose solution, and stir at 300-400 rpm for 5-10 minutes.

[0046] S3. Add rutile titanium dioxide, filler additives and flame retardants, and stir at 800-1000 rpm for 15-20 minutes. It is enough to detect that there are no particles, indicating that the pigments, fillers, and flame retardants have been uniformly dispersed in the solution. If particles are detected, it indicates that there are raw material particles that are not evenly dispersed.

[0047] S4. Add vinyl acetate-ethylene copolymer emulsion, and stir at 400-600 r...

Embodiment 1-5

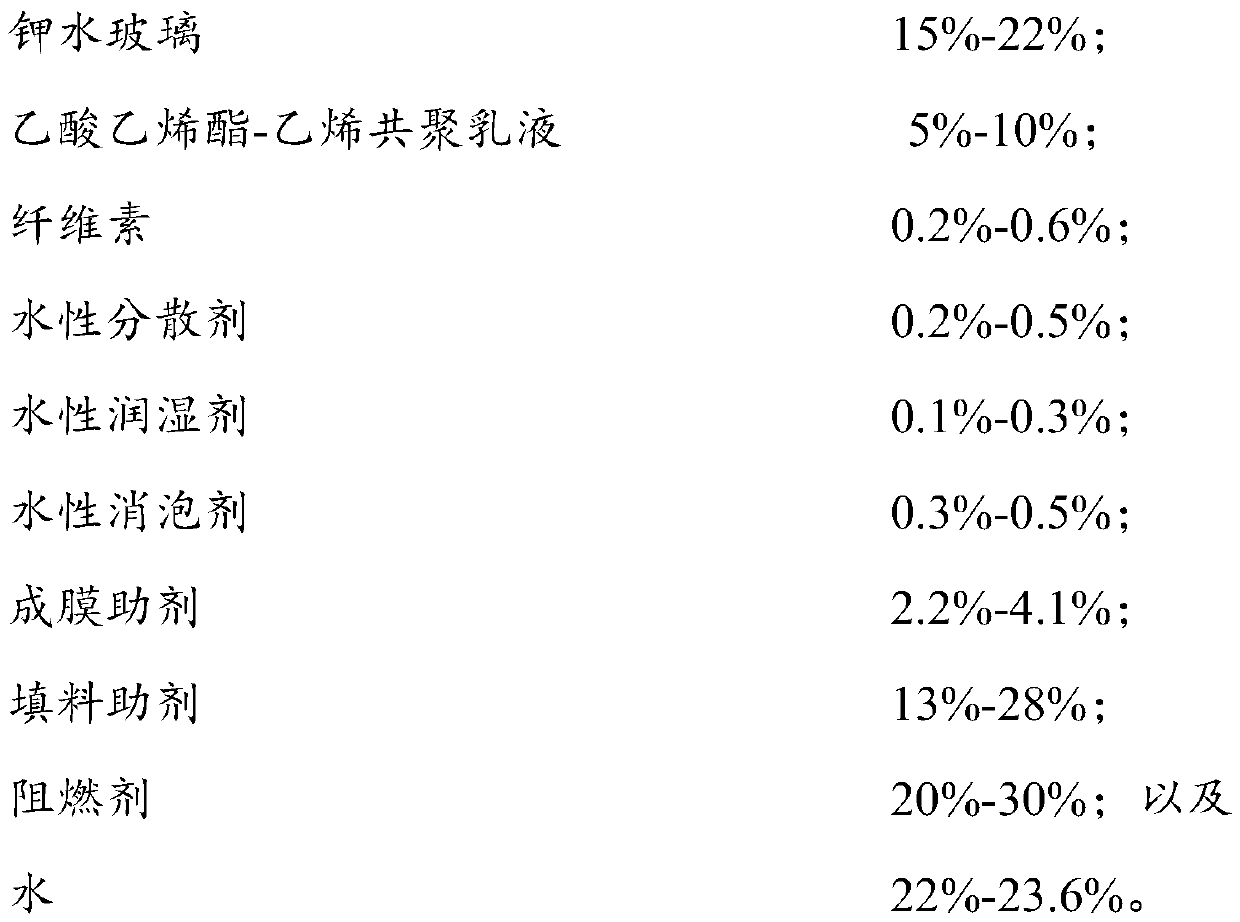

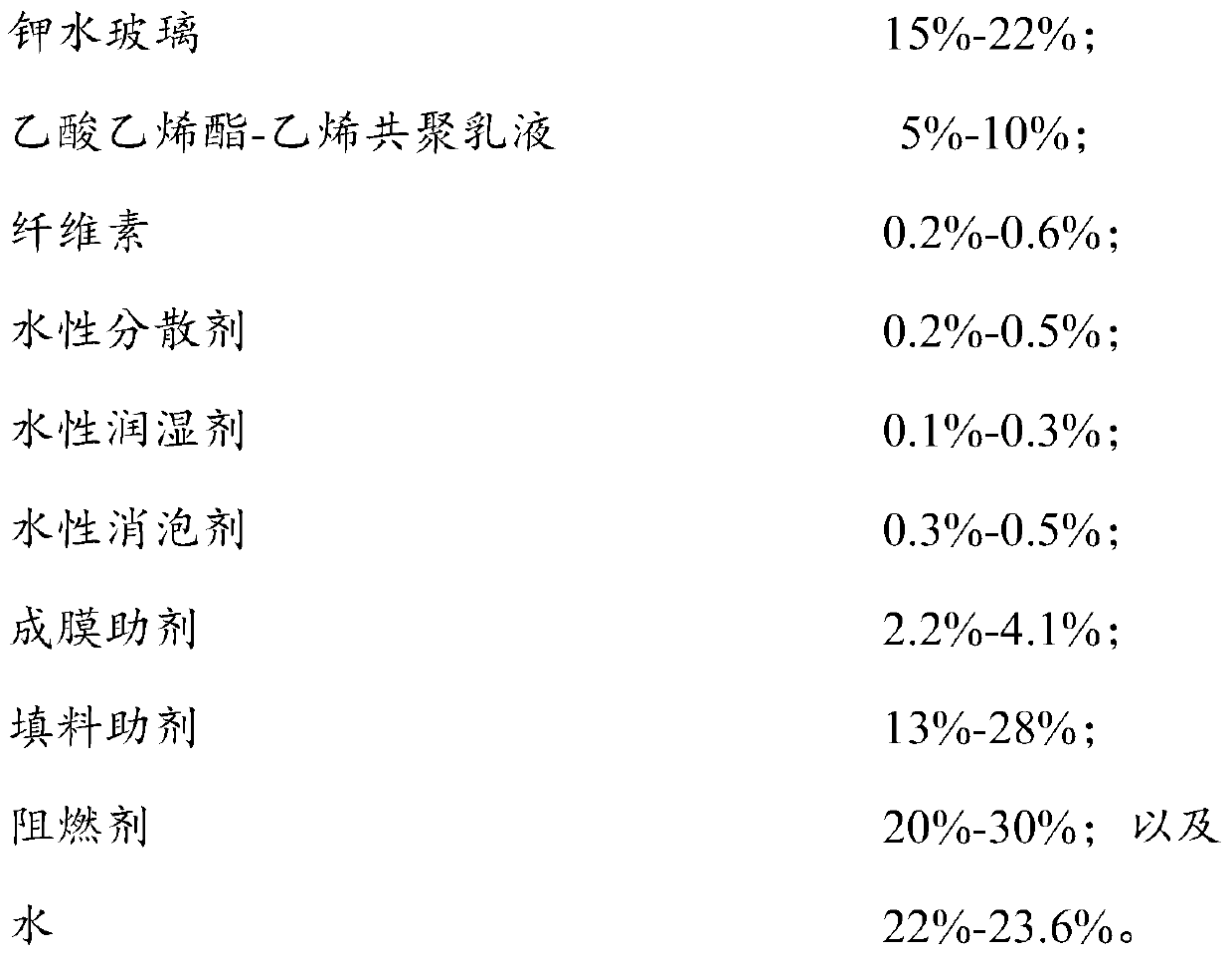

[0053] Each embodiment provides a fireproof coating respectively, model is: GT-NSP-FP2.5-A outdoor intumescent steel structure water-based fireproof coating, the raw material component formula of each embodiment is shown in Table 1.

[0054] The raw material component formula of table 1 embodiment 1-5

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com