Auxiliary power supply system, maglev train and maglev track

A technology for maglev trains and power supply systems, applied to electric vehicles, motor vehicles, electrical components, etc., can solve the problems of high noise and heavy weight of maglev trains, and achieve the effects of simple electrical wiring, light weight, and reduced installation space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

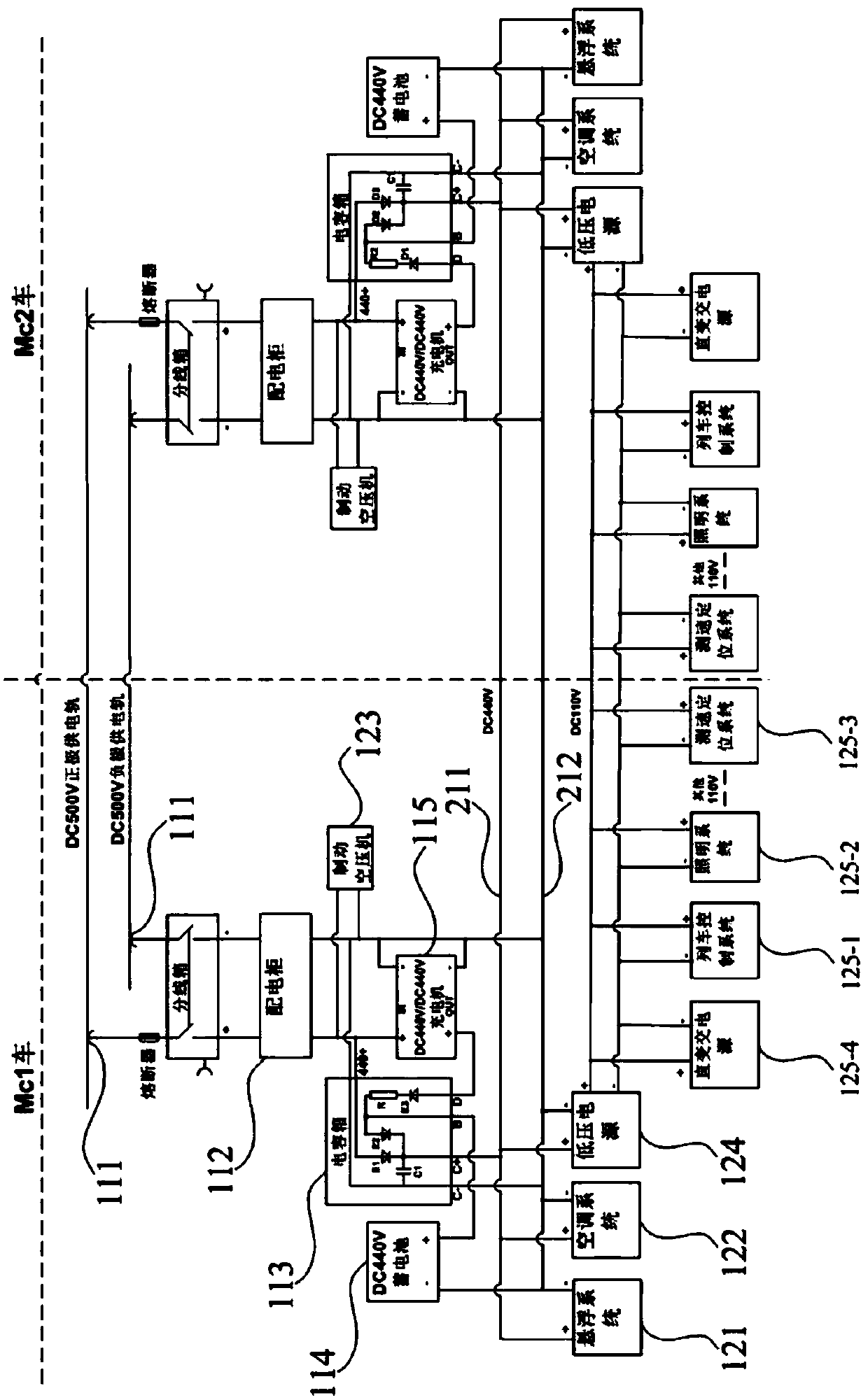

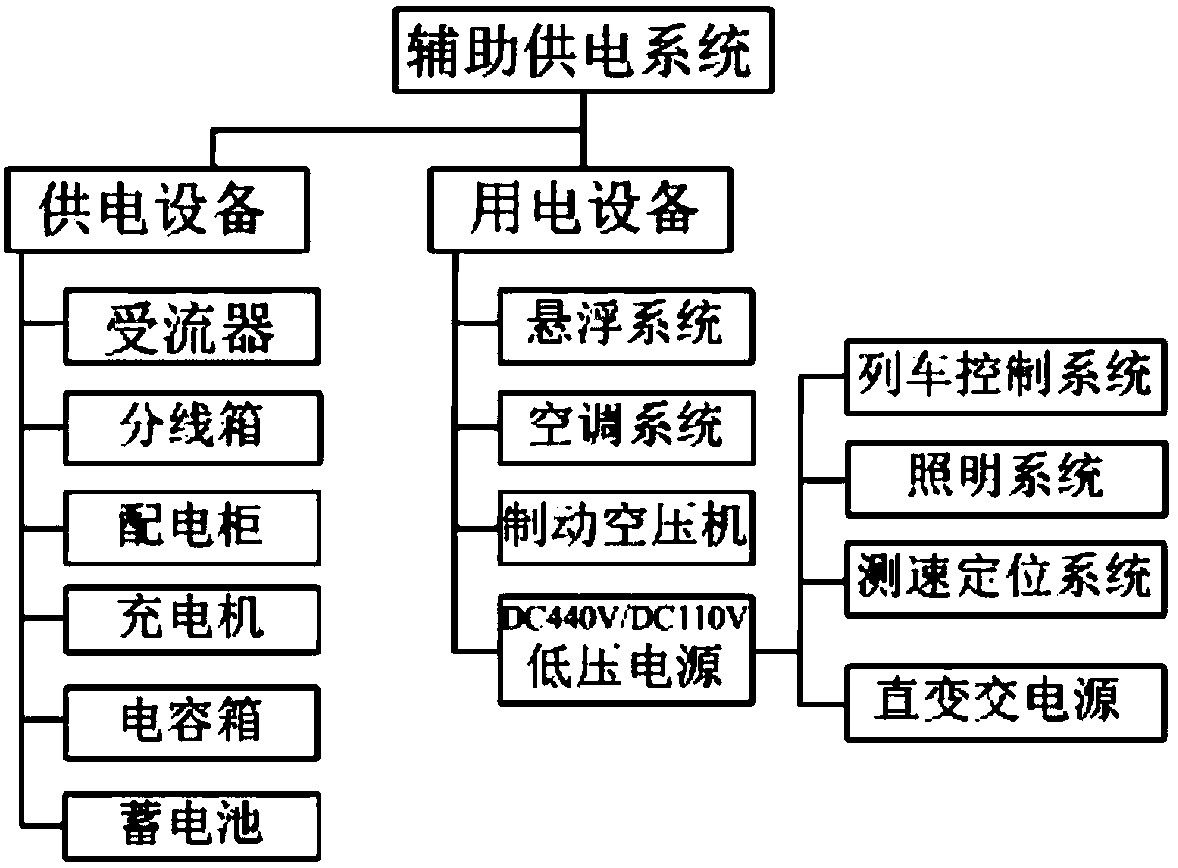

[0045] figure 1 This is a circuit diagram of a magnetic levitation train in an embodiment of this application, figure 2 for figure 1 The structure diagram of the auxiliary power supply system of the maglev train shown. The auxiliary power supply system of the maglev train of the embodiment of the present application, such as figure 1 with figure 2 Shown, including:

[0046] Power supply equipment for taking direct current from an external power supply rail and outputting direct current to the bus of the maglev train; figure 1 In the case, the positive pole of the bus is represented by 211, and the negative pole of the bus is represented by 212;

[0047] Electrical equipment, the electrical equipment is all direct current electrical equipment, and the electrical equipment is powered by the power supply equipment and the busbar of the maglev train.

[0048] In the auxiliary power supply system of the maglev train of the embodiment of the present application, the power supply equipm...

Embodiment 2

[0104] The magnetic levitation train of the embodiment of the present application includes a plurality of train units connected in a row, each of the train units includes an auxiliary power supply system, and the auxiliary power supply system is the auxiliary power supply system described in the first embodiment.

Embodiment 3

[0106] The magnetic levitation track of the third embodiment of the present application includes:

[0107] A power supply rail set on the ground, the rated voltage of the power supply rail is DC 500V, figure 1 In the case of DC500V, the fluctuation range of the power supply voltage of the power supply rail is between 450 volts and 520 volts DC; the power supply rail is used for the power supply of the maglev train described in the second embodiment.

[0108] The magnetic levitation rail of the embodiment of the present application includes a power supply rail set on the ground, the rated voltage of the power supply rail is 500 volts DC, and the fluctuation range of the power supply voltage of the power supply rail is 450 volts to 520 volts DC. Compared with the rated voltage of the power supply rail in the background art, which is DC 1500V, the rated voltage of the power supply rail is lower, which is convenient for the use of the maglev train powered by the power supply rail.

[010...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com