Ga2O3 nano-pillar photocatalytic material based on flexible substrate, and preparation method thereof

A technology of photocatalytic materials and flexible substrates, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as insufficient and difficult to absorb light, Achieve the effect of uniform shape, sufficient light absorption and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

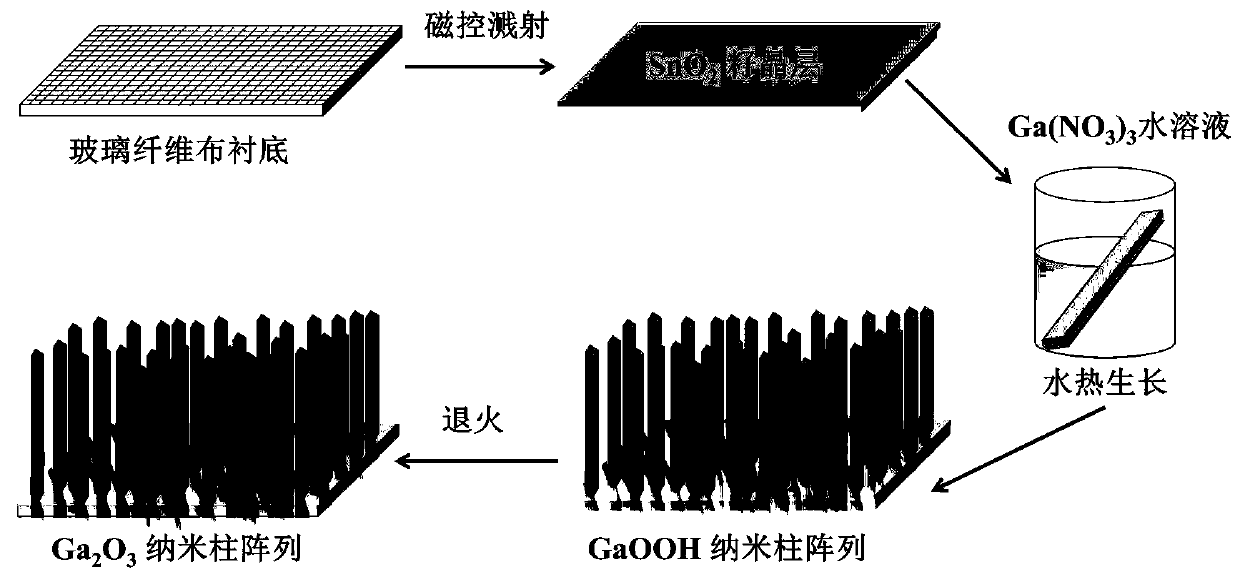

[0053] Ga on flexible substrate 2 o 3 The preparation method of nano column photocatalytic material, comprises the following steps:

[0054] (1) The flexible glass fiber substrate was ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 10 min, and then cleaned with dry N 2 Air-dried, and dried in an oven at 60°C for 12 hours for later use;

[0055] (2) Deposit SnO on the substrate cleaned in step (1) under vacuum by radio frequency magnetron sputtering 2 The film serves as a seed layer for growth and is annealed in a muffle furnace. The specific parameters of the RF magnetron sputtering technology used are as follows: the cavity vacuum is 5×10 -4 Pa, the working atmosphere is Ar and O 2 , the ratio is 1:1, the working pressure is 0.8Pa, the substrate temperature is 550°C, the sputtering power is 100W, and the sputtering time is 4h; the parameters of the muffle furnace annealing treatment used are as follows: the annealing temperature is 550°C ,...

Embodiment 2

[0064] Steps (1) and (2) are the same as those in Embodiment 1, and will not be repeated here.

[0065] (3) The sample obtained after step (2) will be placed in 0.6g / 30mL Ga(NO 3 ) 3 In the growth aqueous solution, the GaOOH nanopillar array was obtained by growing in a stainless steel autoclave at 150°C for 8h, and then placed in a muffle furnace for calcination at 400°C for 4h to obtain the α-Ga2O3 nanopillar array.

[0066] Further can also include step (4), the α-Ga based on flexible substrate 2 o 3 Nanopillar arrays were annealed at 700°C for 20min-120min to prepare different phases of Ga 2 o 3 array of nanopillars. Gained Ga 2 o 3 The chemical composition and morphology of the nanopillar array are similar to Example 1.

Embodiment 3

[0068] Steps (1), (2), and (4) are the same as those in Embodiment 1, and will not be repeated here.

[0069] (3) The sample obtained after step (2) will be placed in 0.3g / 30mL Ga(NO 3 ) 3 In the growth solution, grow in a stainless steel autoclave at 150 °C for 10 h to obtain GaOOH nanopillar arrays, and then place them in a muffle furnace for calcination at 400 °C for 4 h to obtain α-Ga 2 o 3 array of nanopillars. Gained Ga 2 o 3 The chemical composition and morphology of the nanopillar array are similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com