Automatic winding machine for self-adhesion elastic bandage

A self-adhesive elastic bandage and automatic tape winding technology, which is applied in bandages, medical science, etc., can solve the problems of destroying product performance, manual cutting of products, manual replacement of paper cores, etc., and achieve the effect of improving tape winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

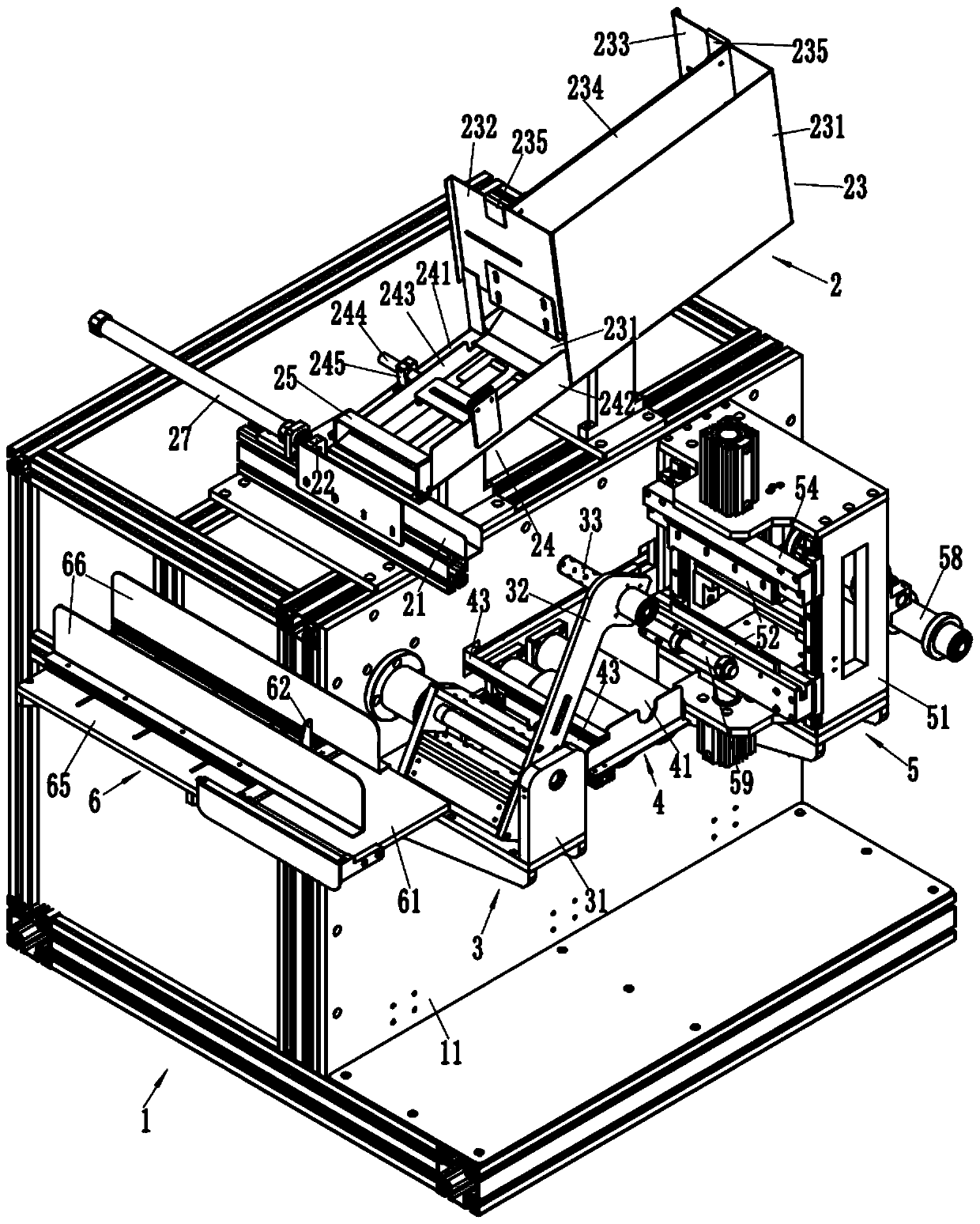

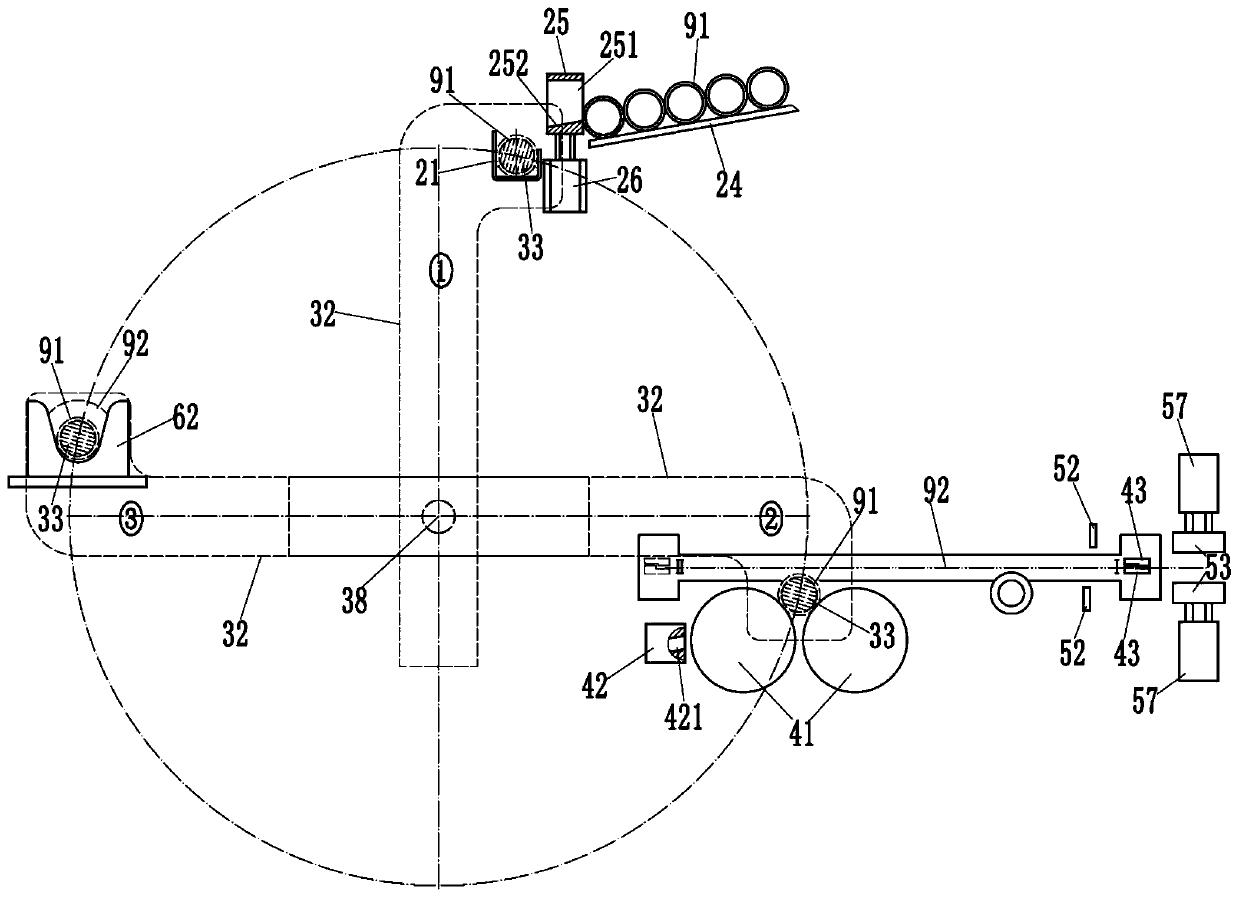

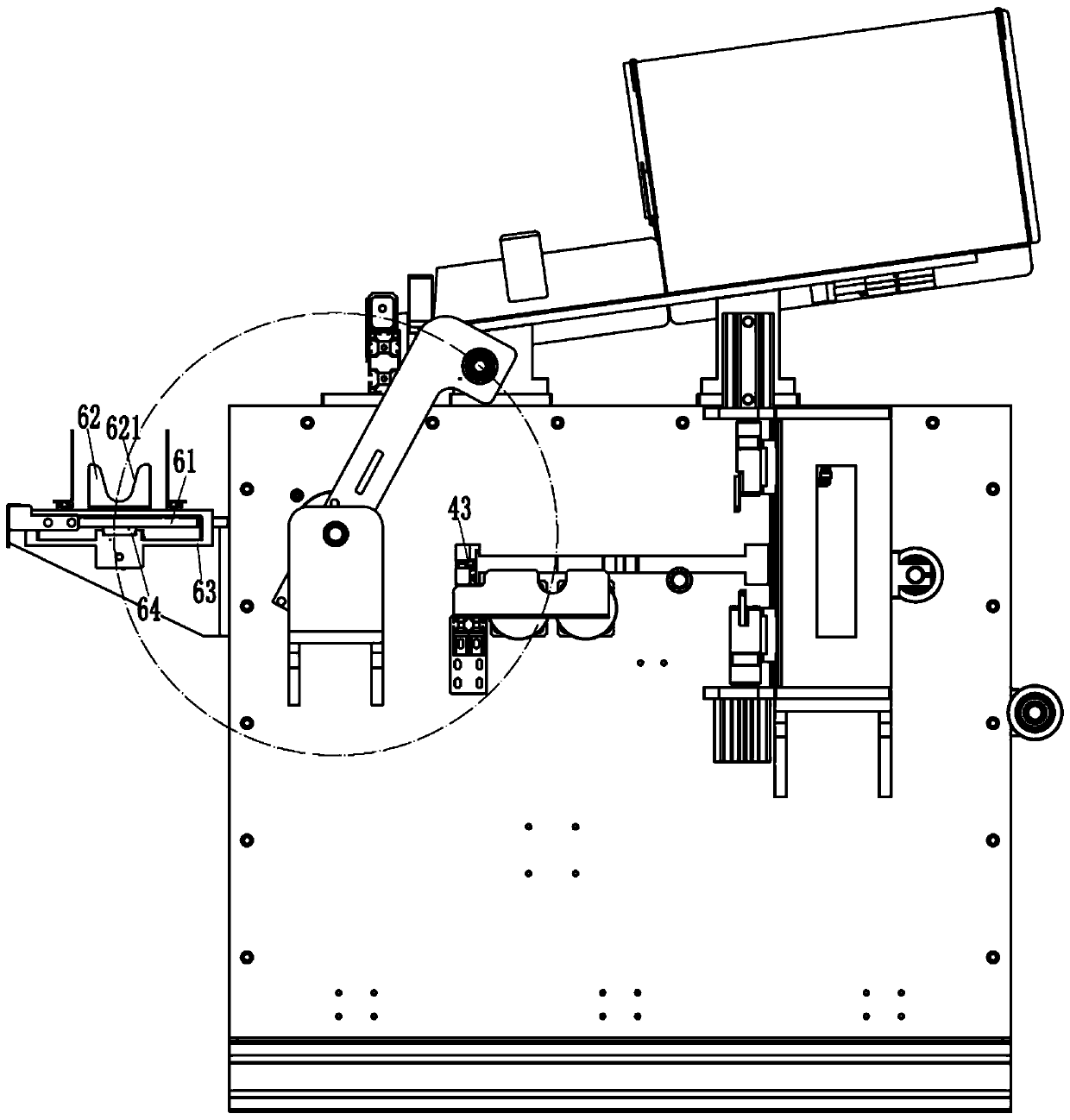

[0035] Examples, see e.g. Figure 1 to Figure 9 As shown, a self-adhesive elastic bandage automatic winding machine includes a frame 1, and the frame 1 is provided with a paper core feeding mechanism 2, a paper core transfer mechanism 3, a winding mechanism 4, bandage feeding and cutting Mechanism 5 and bandage roll discharge mechanism 6;

[0036] The paper core feeding mechanism 2 includes a "U"-shaped paper core feeding channel 21 fixed above the frame 1, and a paper core pushing block 22 that can move forward and backward is arranged in the paper core feeding channel 21;

[0037]The take-up mechanism 4 includes a pair of take-up rollers 41 symmetrically arranged at the bottom right of the paper core feeding channel 21, a blowing part 42 located on the left side of the two take-up rollers 41, and a belt blower located above the two take-up rollers 41. Two entrainment slats 43 arranged up and down, two entrainment slats 43 are provided with a translation mechanism 7 that dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com