A device and method for online testing of ferrous iron and total iron content in a sample

A technology for ferrous iron and iron content, applied in the preparation of test samples, measuring devices, color/spectral characteristics measurement, etc., can solve the problems of unsatisfactory accuracy, complicated detection methods, and long detection cycle, etc., and achieve reduction Labor intensity, reduce the risk of being oxidized, and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

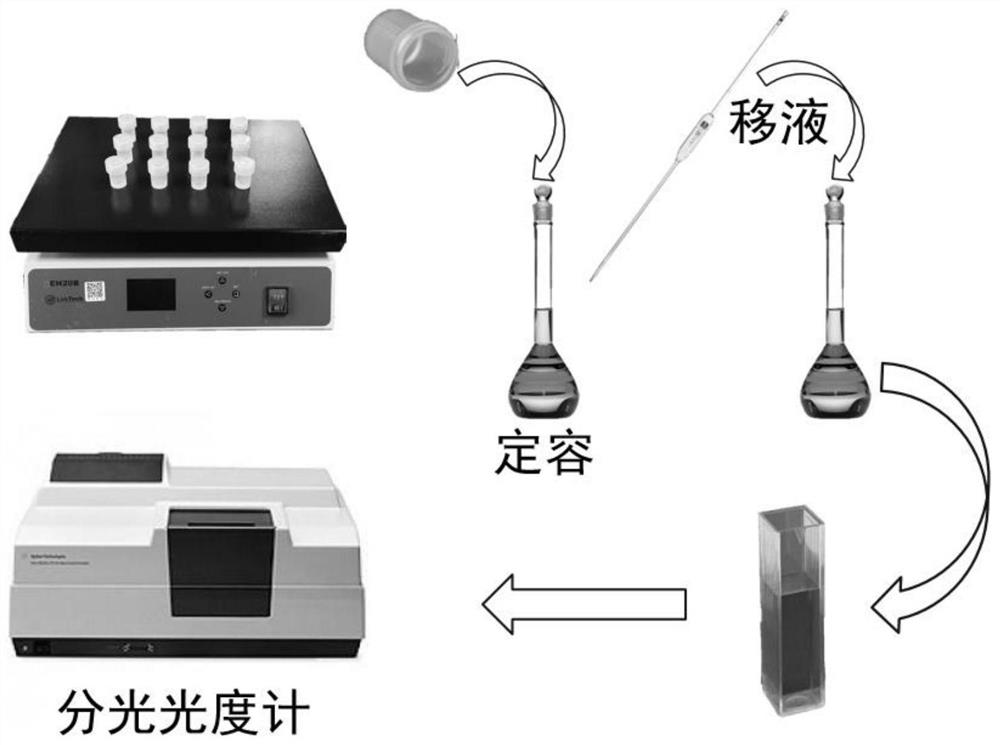

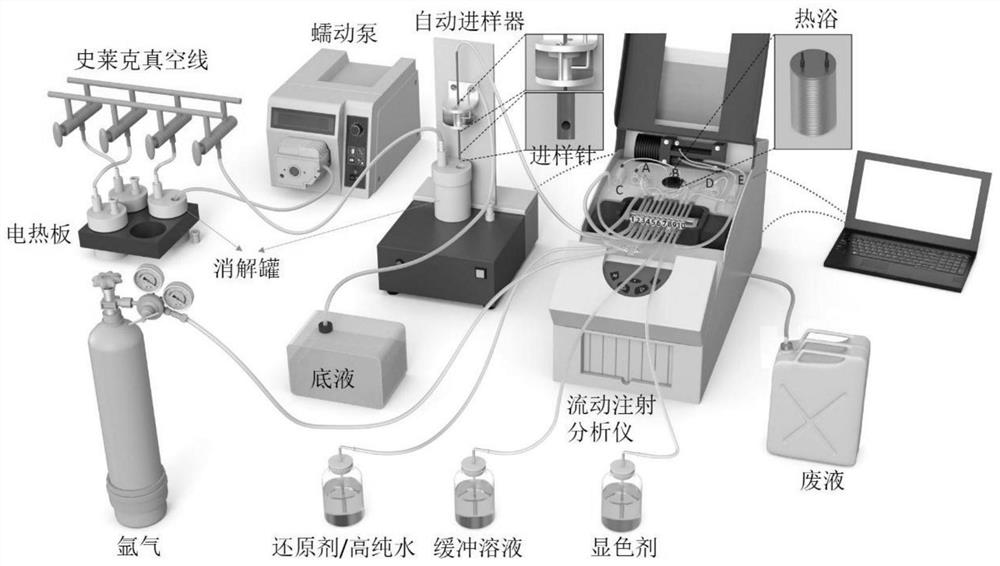

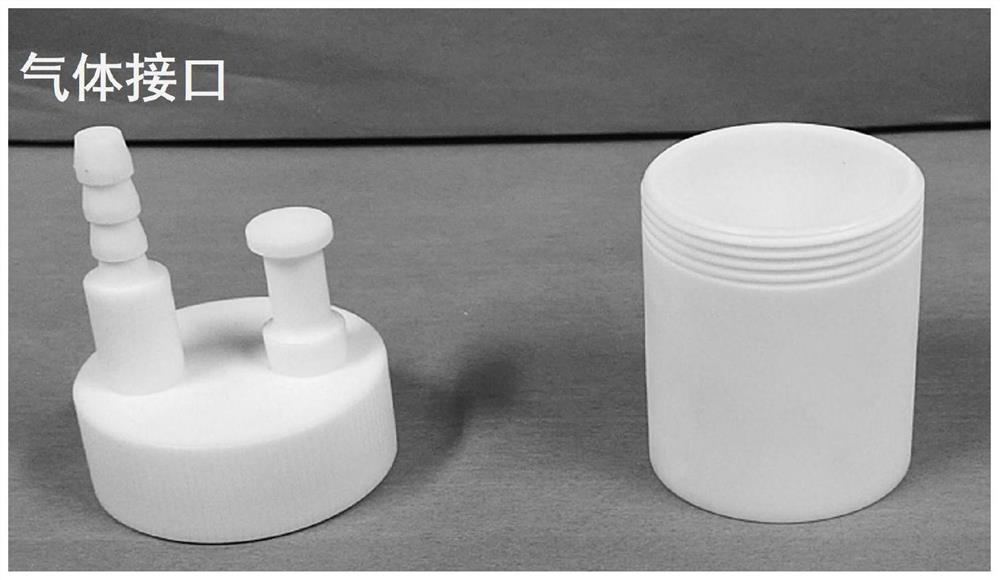

[0067] Digestion and constant volume: Accurately weigh 2-8 mg of standard geological sample JB-1a and place it in the Teflon sample dissolving tank, tighten the screw cap, and connect the vent hole to the Shrek vacuum line; plug the cap tightly, and then vacuumize first , and then introduce argon, repeat the operation three times; open the lid, add sulfuric acid (9mol / L) 0.6mL, hydrofluoric acid 0.4mL with a pipette gun in the argon flow; heat and digest on the electric heating plate for 6 minutes; digestion is complete Finally, add 4.0 mL of saturated boric acid in the argon flow; add 95.0 mL of high-purity water in the argon flow to make constant volume;

[0068] Test: The sample solution after constant volume is directly introduced into the flow injection analyzer for analysis; the specific operation is that the sample solution enters the flow injection analyzer through No. 1 sample pipe. At the same time, reducing agent or water (when analyzing total iron, the liquid used ...

Embodiment 2

[0074] The other steps are the same as in Example 1, except that the rock standard material JG-1a is used, ferrozine is used as the chromogen, and the sample solution after constant volume is directly introduced into the flow injection analyzer for analysis. The number of measurements is 5 times. Utilize above-mentioned determination method to the comparison of the measured value and standard value of ferrous iron and total iron in the international standard substance JG-1a as shown in table 2:

[0075] Table 2

[0076]

Embodiment 3

[0078] Other steps are the same as in Example 1, except that the rock standard material JR-2 is used, and the sample solution after constant volume is directly introduced into a flow injection analyzer for analysis. The number of measurements is 5 times. Utilize above-mentioned determination method to the comparison of the measured value and standard value of ferrous iron and total iron in international standard substance JG-1a as shown in table 3:

[0079] table 3

[0080]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com