A method for efficient heat exchange of a fanless solid heat storage electric boiler

A solid heat storage and electric boiler technology, which is applied to heat storage heaters, fluid heaters, lighting and heating equipment, etc. Work efficiency, improve heat exchange efficiency, and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

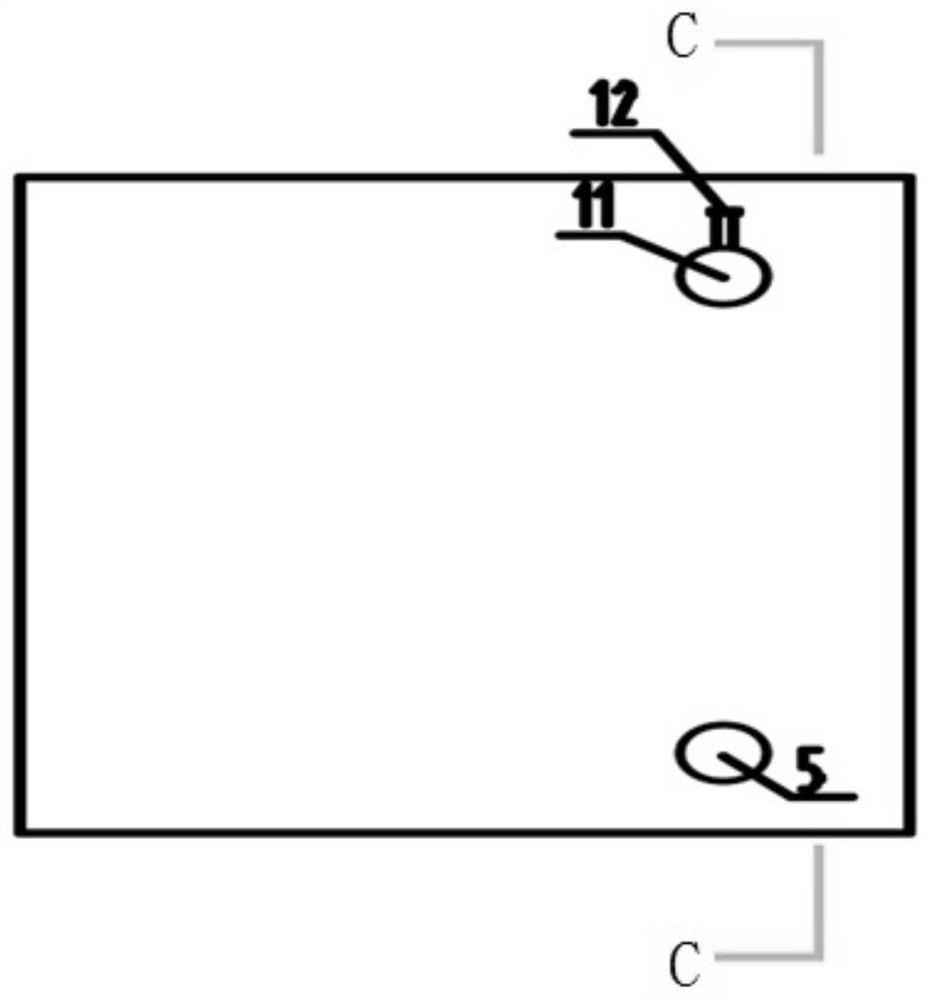

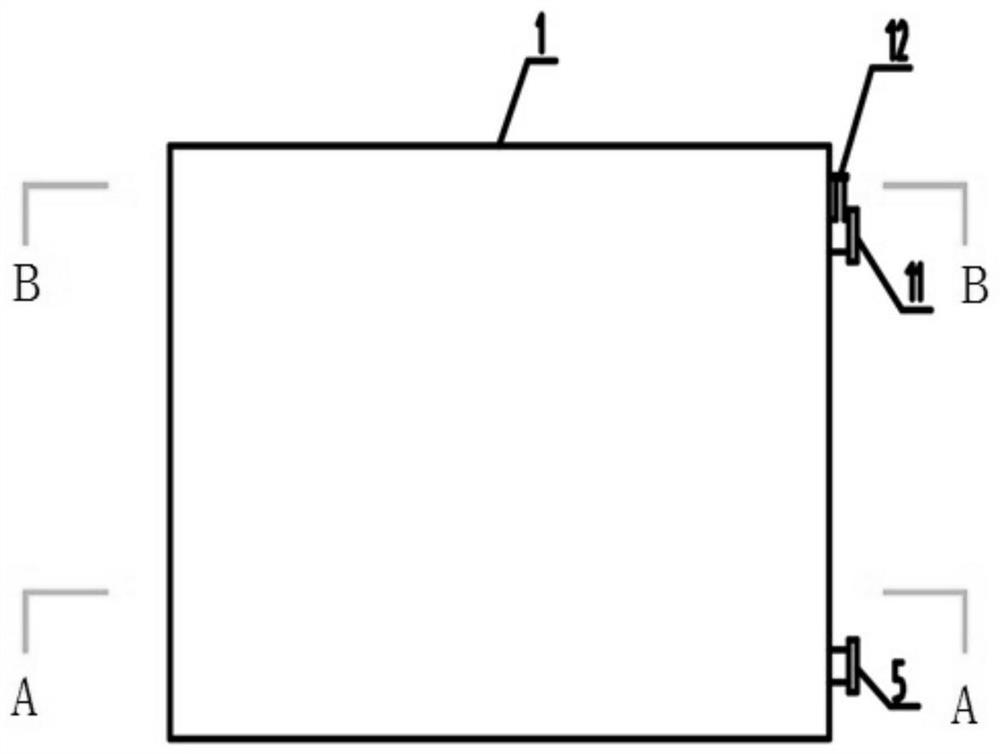

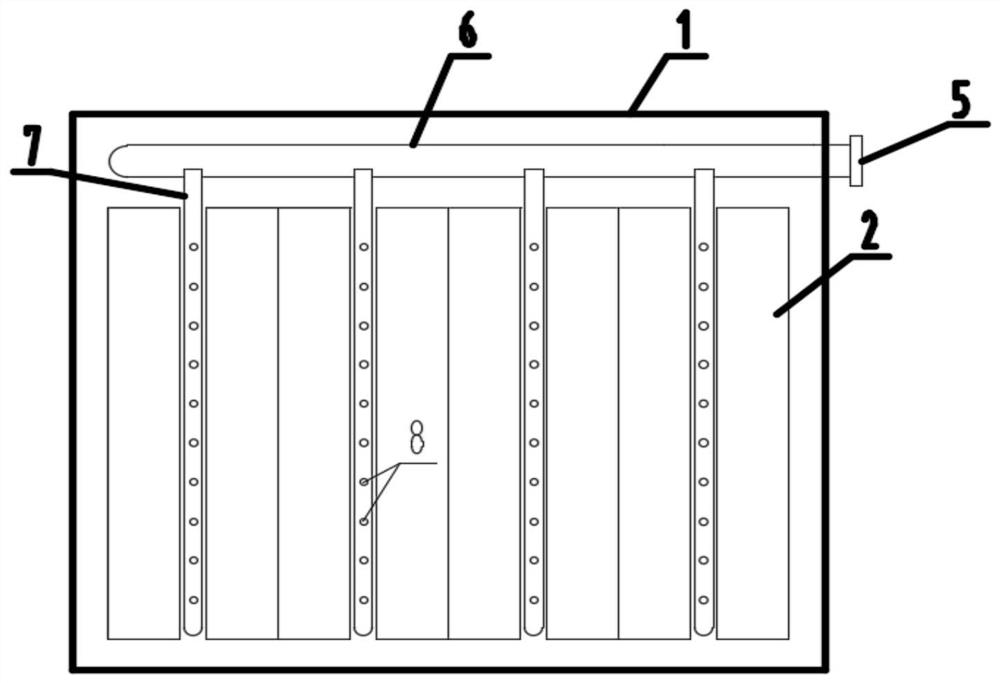

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0036] as follows Figure 1-8 As shown, a method for efficient heat exchange of a fanless solid heat storage electric boiler of the present invention includes the following content: evenly distribute the return water of the heating system in the solid heat storage electric boiler, and realize the return water of the internal heating system and the heat storage body 2 Measures for uniform heat exchange, uniform confluence of water supply for heating, prevention of internal heat leakage, and measures to avoid medium vaporization in internal pipelines during heating;

[0037] Step 1: Evenly distribute the return water of the heating system in the solid heat storage electric boiler

[0038] In order to make the return water of the solid heat storage electric boiler heating system enter the interior of the solid heat storage electric boiler, a pipe with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com