Epoxy chopped carbon fiber felt prepreg for rapid prototyping and production process thereof

A short-cut carbon fiber and prepreg technology, applied in the field of resin-based composite materials, can solve the problems of complex layup design, carbon fiber is not easy to disperse uniformly, and material utilization rate is low. VOC environmental protection requirements, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An epoxy chopped carbon fiber mat prepreg for rapid prototyping comprising an areal density of 300g / m 2 The percentage by weight of ELG reclaiming chopped carbon fiber mat A3 is 39%, and the epoxy resin composition weight percentage that can be thickened rapidly obtained after the fast curing epoxy resin and isophorone diamine thickener is mixed is 61%; Wherein , The weight ratio of fast curing epoxy resin and isophorone diamine thickener is 100:5.4.

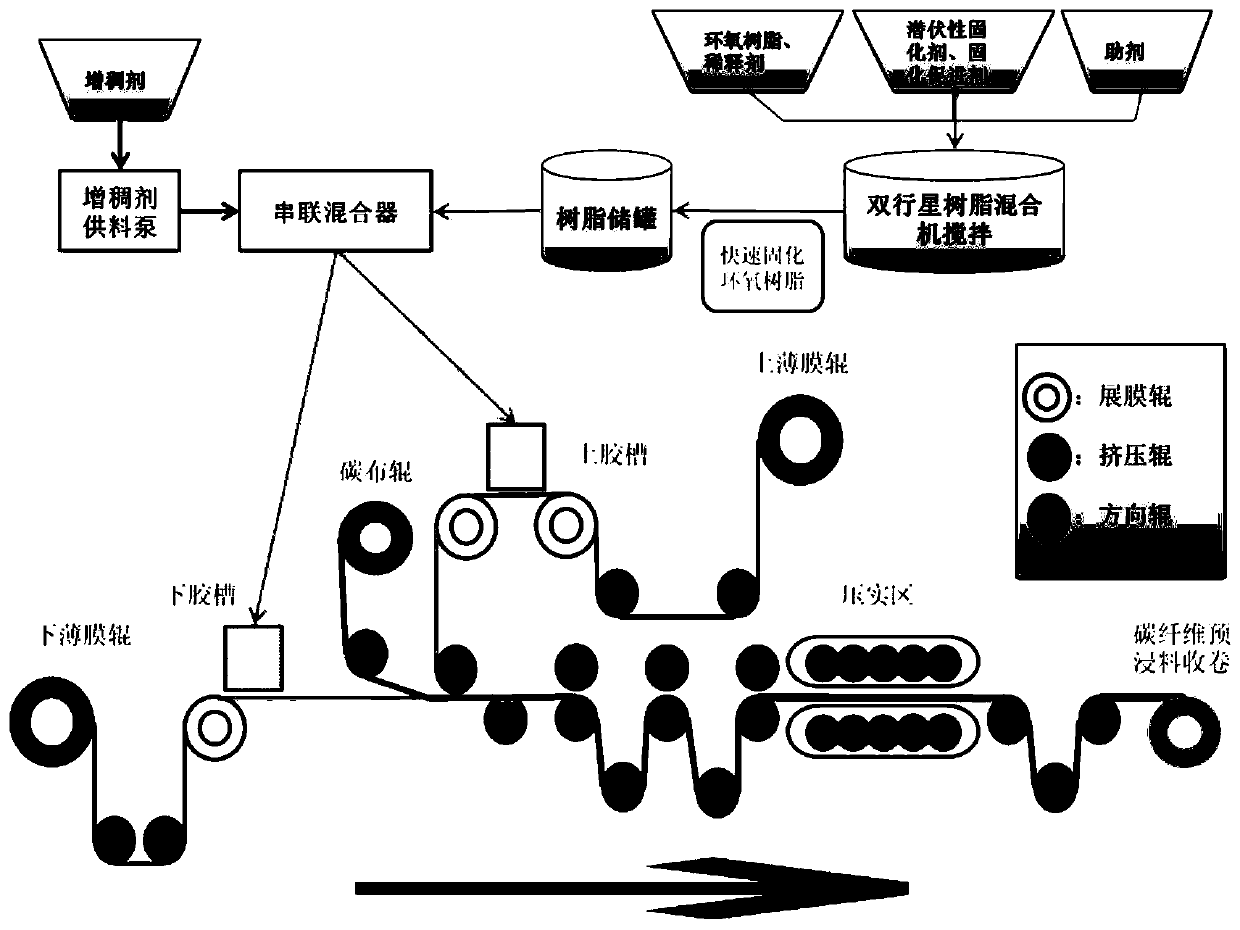

[0044] A production process of epoxy chopped carbon fiber felt prepreg for rapid prototyping, the process flow is as follows figure 1 shown, including the following steps:

[0045] a. Add epoxy resin, active diluent containing three epoxy functional groups, hydrazide curing agent, organic urea and modified imidazole curing accelerator, sizing agent and defoamer to the twin-axis resin mixer and stir to obtain a fast Curing the epoxy resin composition and storing it in a resin storage tank;

[0046] b. The fast-curing e...

Embodiment 2

[0059] An epoxy chopped carbon fiber mat prepreg for rapid prototyping, including an areal density of 200 g / m 2 The percentage by weight of ELG reclaiming chopped carbon fiber mat A2 is 30%, and the epoxy resin composition weight percentage that can be thickened rapidly obtained after the fast curing epoxy resin and isophorone diamine thickener is mixed is 70%; Wherein , The weight ratio of fast curing epoxy resin and isophorone diamine thickener is 100:5.4.

[0060] A production process of epoxy chopped carbon fiber felt prepreg for rapid prototyping, comprising the following steps:

[0061] a. Add epoxy resin, active diluent containing three epoxy functional groups, hydrazide curing agent, organic urea and modified imidazole curing accelerator, sizing agent and defoamer to the twin-axis resin mixer and stir to obtain a fast Curing the epoxy resin composition and storing it in a resin storage tank;

[0062] b. The fast-curing epoxy resin composition and the isophorone diam...

Embodiment 3

[0075] An epoxy chopped carbon fiber mat prepreg for rapid prototyping comprising an areal density of 400g / m 2The percentage by weight of ELG reclaiming chopped carbon fiber felt A4 is 39%, and the rapidly thickening epoxy resin composition weight percentage obtained after the mixing of fast-curing epoxy resin and isophorone diamine thickener is 61%; wherein , The weight ratio of fast curing epoxy resin and isophorone diamine thickener is 100:5.4.

[0076] A production process of epoxy chopped carbon fiber felt prepreg for rapid prototyping, comprising the following steps:

[0077] a. Add epoxy resin, reactive diluent containing two epoxy functional groups, dicyandiamide, organic urea and modified imidazole curing accelerator, sizing agent and defoamer to the twin-axis resin mixer and stir to obtain rapid curing An epoxy resin composition stored in a resin storage tank;

[0078] b. The fast-curing epoxy resin composition and the isophorone diamine thickener are pumped into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com